Imigaqo esisiseko yoyilo lwephedi yePCB

Ngokohlalutyo lwesakhiwo esidityanisiweyo se-solder samacandelo ahlukeneyo, ukuze kuhlangatyezwane neemfuno zokuthembeka kwamalungu e-solder, uyilo lwephedi yePCB kufuneka lulawule ezi zinto zibalulekileyo zilandelayo:

I-1, i-symmetry: zombini iziphelo zepadi kufuneka zilingane, ukwenzela ukuba kuqinisekiswe ukulingana koxinzelelo lwe-solder etyhidiweyo.

2. Isithuba sepadi: Qinisekisa ubungakanani obufanelekileyo bomphetho wecandelo okanye iphini kunye nepad.Isithuba esikhulu kakhulu okanye esincinci kakhulu sepadi siya kubangela iziphene kwi-welding.

3. Ubungakanani obusele bepadi: ubungakanani obuseleyo becandelo lesiphelo okanye ipini emva kokuqhawula kunye nephedi kufuneka kuqinisekiswe ukuba i-solder joint ingenza i-meniscus.

4.Ububanzi bePad: Kufuneka buhambelane ngokusisiseko nobubanzi besiphelo okanye isikhonkwane secandelo.

iingxaki Solderability ezibangelwa iziphene uyilo

01. Ubungakanani bepadi buhluka

Ubungakanani boyilo lwepadi kufuneka buhambelane, ubude bufanele bufanelekele uluhlu, ubude bokwandiswa kwepadi bunoluhlu olufanelekileyo, olufutshane kakhulu okanye olude kakhulu luxhomekeke kwinto ye-stele.Ubungakanani bepadi abuhambisani kwaye ukuxhatshazwa akulingani.

02. Ububanzi bepadi bubanzi kunepini yesixhobo

Uyilo lwePad alunakuba banzi kakhulu kunamacandelo, ububanzi bepadi bububanzi obuyi-2mil ngaphezu kwamacandelo.Ububanzi bephedi ebanzi kakhulu buya kukhokelela ekususweni kwecandelo, ukuwelda emoyeni kunye netoti engonelanga kwipadi kunye nezinye iingxaki.

03. Ububanzi bepadi bumxinwa kunephini lesixhobo

Ububanzi boyilo lwe-pad buncinci kunobubanzi bamacandelo, kwaye indawo yokudibanisa i-pad kunye namacandelo incinci xa i-SMT i-patches, elula ukubangela ukuba amacandelo ame okanye ajike.

04. Ubude bepadi bude kunepini yesixhobo

I-pad eyiliweyo akufanele ibe yinde kakhulu kunepini yecandelo.Ngaphandle koluhlu oluthile, ukuhamba ngokugqithiseleyo kwe-flux ngexesha le-SMT reflow welding kuya kubangela ukuba icandelo litsale indawo ye-offset kwicala elinye.

05. Isithuba phakathi kweepads sifutshane kuneso samacandelo

Ingxaki ye-short-circuit ye-pad spacing ngokubanzi iyenzeka kwi-IC pad spacing, kodwa i-design ye-spacing yangaphakathi yezinye iipads ayikwazi ukuba mfutshane kakhulu kune-pin ye-spacing yamacandelo, eya kubangela isiphaluka esifutshane ukuba idlula uluhlu oluthile lwamaxabiso.

06. Ububanzi bepini yephedi buncinci kakhulu

Kwi-SMT patch yecandelo elifanayo, iziphene kwi-pad ziya kubangela ukuba icandelo likhuphe.Umzekelo, ukuba i-pad incinci kakhulu okanye inxalenye yepedi incinci kakhulu, ayiyi kwenza i-tin okanye i-tin encinci, ibangele ukuxinana okwahlukileyo kuzo zombini iziphelo.

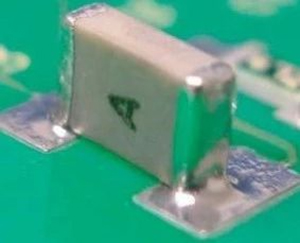

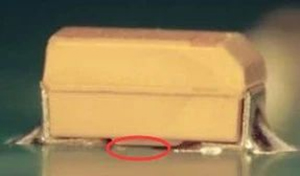

Iimeko zangempela zeepads ezincinci ze-bias

Ubungakanani bepads eziphathekayo abuhambelani nobukhulu bepakethe yePCB

Inkcazo yengxaki:Xa imveliso ethile iveliswa kwi-SMT, kufunyenwe ukuba i-inductance ivaliwe ngexesha lokuhlolwa kwe-welding yangasemva.Emva kokuqinisekiswa, kufunyenwe ukuba izinto ze-inductor azihambelani neepads.*1.6mm, imathiriyeli iya kubuyiselwa umva emva kwe-welding.

Impembelelo:Uxhulumaniso lombane lwezinto eziphathekayo luba lubi, luchaphazela ukusebenza kwemveliso, kwaye lubangela ukuba imveliso ingakwazi ukuqala ngokuqhelekileyo;

Ukwandiswa kwengxaki:Ukuba ayinakuthengwa kubukhulu obufanayo ne-PCB pad, inzwa kunye nokuchasana kwangoku kunokuhlangabezana nezinto ezifunwa yisekethe, ngoko umngcipheko wokutshintsha ibhodi.

Ixesha lokuposa: Apr-17-2023