Inkqubo yemveliso yePCBA eneenkcukacha (kubandakanywa yonke inkqubo yeDIP), ngena kwaye ubone!

"Inkqubo yeSoldering yamaza"

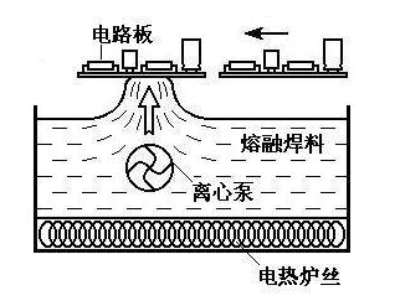

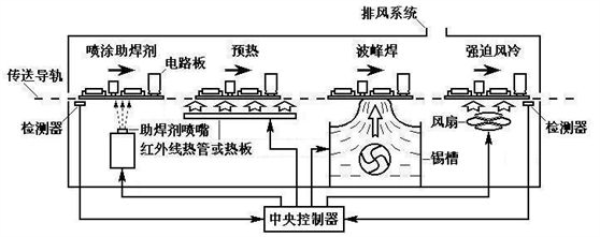

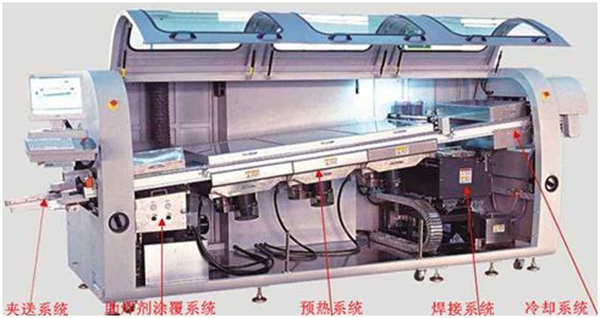

I-Wave soldering ngokuqhelekileyo yinkqubo ye-welding yezixhobo ze-plug-in. Yinkqubo apho i-solder yolwelo olunyibilikisiweyo, ngoncedo lwempompo, yenza imilo ethile ye-solder wave kumphezulu wolwelo wetanki ye-solder, kwaye iPCB yecandelo elifakiweyo idlula kwincopho ye-solder wave kwindawo ethile. I-Angle kunye nobunzulu bokuntywiliselwa kwikhonkco lokuhambisa ukuphumeza i-solder joint welding, njengoko kuboniswe kumzobo ongezantsi.

Inkqubo yokuhamba ngokubanzi ihamba ngolu hlobo lulandelayo: ukufakwa kwesixhobo --PCB ukulayishwa -- wave soldering --PCB ukothulwa --DIP pin trimming -- ukucoca, njengoko kubonisiwe kumfanekiso ongezantsi.

I-1.THC iteknoloji yokufaka

1. Ukwenza isikhonkwane secandelo

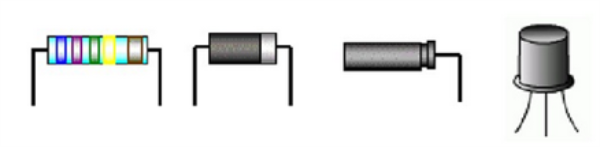

Izixhobo ze-DIP kufuneka zibunjwe phambi kokufakwa

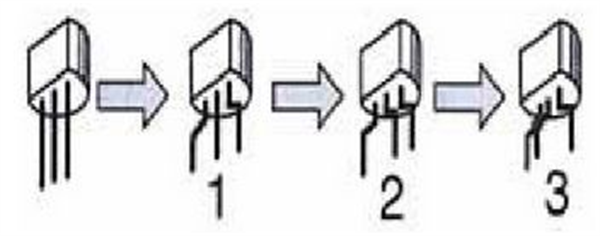

(1) Ukubunjwa kwecandelo elicutshungulwe ngesandla: Iphini eligobileyo linokwakheka nge-tweezers okanye i-screwdriver encinci, njengoko kubonisiwe kulo mfanekiso ungezantsi.

(2) Ukulungiswa komatshini wamacandelo okubunjwa: ukubunjwa komatshini wamacandelo kugqitywe ngoomatshini bokubunjwa obukhethekileyo, umgaqo wayo wokusebenza kukuba i-feeder isebenzisa i-vibration feeding kwi-feed materials, (ezifana ne-plug-in transistor) kunye nesahluli ukufumana indawo. i-transistor, inyathelo lokuqala kukugoba izikhonkwane kumacala omabini kwicala lasekhohlo nasekunene; Isinyathelo sesibini kukugoba iphini eliphakathi ngasemva okanye phambili kwifom. Njengoko kubonisiwe kumfanekiso olandelayo.

2. Faka amacandelo

Ngokusebenzisa iteknoloji yokufaka umngxuma yahlulwe ngokufaka ngesandla kunye nokufakwa kwezixhobo ezizenzekelayo

(1) Ukufakwa ngesandla kunye nokuwelda kufuneka kuqala kufakwe ezo nxalenye kufuneka zilungiswe ngoomatshini, njengesixhobo sokupholisa, isibiyeli, ikliphu, njl.njl., yesixhobo sombane, emva koko sifake amacandelo afuna ukudityaniswa kunye nokulungiswa. Musa ukuthintela izikhonkwane zecandelo kunye ne-foil yobhedu kwi-plate yokushicilela ngokuthe ngqo xa ufaka.

(2) I-plug-in ye-Mechanical automatic (ebizwa ngokuba yi-AI) yeyona nto iphezulu kakhulu iteknoloji yokuvelisa i-automated ekufakeni iimveliso ze-elektroniki zangoku. Ufakelo lwezixhobo zoomatshini ezizenzekelayo kufuneka kuqala kufakwe ezo zixhobo ezinobude obuphantsi, kwaye emva koko kufakwe ezo zixhobo ezinobude obuphezulu. Amacandelo abalulekileyo abalulekileyo kufuneka afakwe kufakelo lokugqibela. Ukufakwa kwe-rack dissipation rack, i-bracket, i-clip, njl. Kufuneka ibe kufuphi nenkqubo ye-welding. Ulandelelwano lwendibano yamacandelo ePCB luboniswe kulo mfanekiso ulandelayo.

3. I-wave soldering

(1) Umgaqo wokusebenza we-wave soldering

I-Wave soldering luhlobo lwetekhnoloji eyenza imilo ethile ye-solder wave phezu komphezulu we-solder yolwelo olutyhidiweyo ngokumpompa uxinzelelo, kwaye yenza indawo ye-solder kwindawo ye-pin welding xa icandelo lendibano elifakwe kunye necandelo lidlula kwi-solder. wangawangisa ngeAngile esisigxina. Icandelo liqala ukufudumeza kwindawo yokutshisa umatshini we-welding ngexesha lenkqubo yokuhanjiswa ngumqhubi we-chain (icandelo lokufudumeza kunye nokushisa okuza kuphunyezwa lisalawulwa yi-curve echazwe kwangaphambili). Kwi-welding yangempela, ngokuqhelekileyo kuyimfuneko ukulawula ukushisa kwangaphambili kwendawo yecandelo, ngoko ke izixhobo ezininzi zongeze izixhobo zokubona ubushushu obuhambelanayo (ezifana ne-infrared detectors). Emva kokufudumeza, indibano ingena kwi-groove ekhokelela kwi-welding. Itanki yenkcenkce iqulethe i-solder yolwelo olutyhidiweyo, kwaye umlomo wombhobho osemazantsi wetanki yentsimbi utshiza i-wave wave crest emileyo ye-solder etyhidiweyo, ukuze xa umphezulu we-welding wecandelo udlula kwi-wave, ufudunyezwe liza le-solder. , kwaye i-solder wave nayo imanzisa indawo ye-welding kwaye iyanda ukuze igcwalise, ekugqibeleni ifezekise inkqubo ye-welding. Umgaqo wayo wokusebenza uboniswe kumzobo ongezantsi.

I-Wave soldering isebenzisa umgaqo wokuhambisa ubushushu ukufudumeza indawo ye-welding. I-solder etyhidiweyo isebenza njengomthombo wobushushu, kwelinye icala ligeleza ukuhlamba indawo ye-pin welding, kwelinye icala nayo idlala indima yokuqhuba ubushushu, kwaye indawo ye-pin welding ishushu phantsi kwesi senzo. Ukuze kuqinisekiswe ukuba indawo ye-welding iyatshisa, i-wave ye-solder ngokuqhelekileyo inobubanzi obuthile, ukwenzela ukuba xa i-welding surface yecandelo idlula kwi-wave, kukho ukufudumeza okwaneleyo, ukumanzisa, njalo njalo. Kwi-solder yemveli, i-wave enye isetyenziswa ngokubanzi, kwaye i-wave ithe tyaba. Ngokusetyenziswa kwe-lead solder, okwangoku yamkelwa ngendlela ye-double wave. Njengoko kubonisiwe kumfanekiso olandelayo.

I-pin yecandelo ibonelela ngendlela yokuba i-solder ingene kwi-metallized ngokusebenzisa umngxuma kwisimo esiqinileyo. Xa isikhonkwane sichukumisa i-solder wave, i-solder yolwelo ikhwela i-pin kunye nodonga lomngxuma ngendlela yoxinzelelo lomphezulu. Isenzo se-capillary ye-metallized ngokusebenzisa imingxuma iphucula ukunyuka kwe-solder. Emva kokuba i-solder ifike kwi-pad ye-PcB, isasazeka phantsi kwesenzo soxinzelelo lomphezulu we-pad. I-solder ekhuphukayo ikhupha igesi ephumayo kunye nomoya ukusuka kumngxuma wokutyhutyha, ngaloo ndlela igcwalisa umngxuma wokutyhutyha kwaye yenze i-solder joint emva kokupholisa.

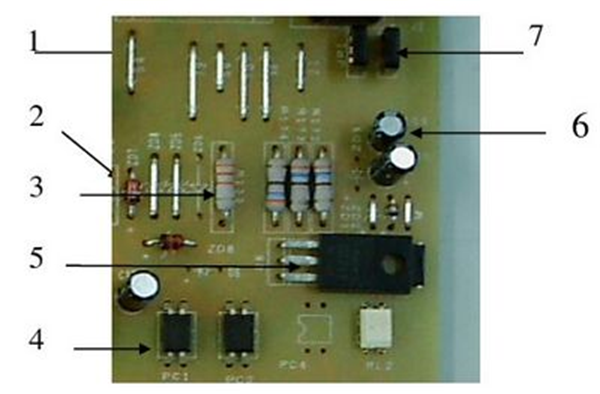

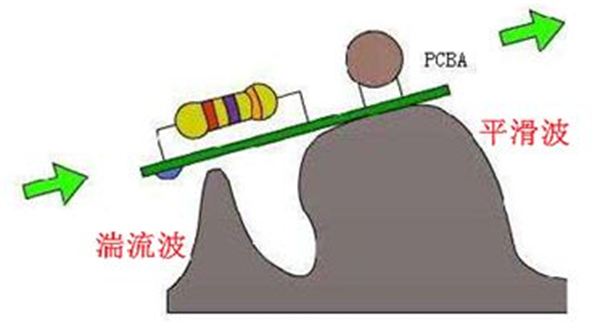

(2) Amacandelo aphambili omatshini wokuwelda amaza

Umatshini wokuwelda wamaza wenziwa ikakhulu libhanti lokuhambisa, isifudumezi, itanki yetoti, impompo, kunye nesixhobo sokutshiza (okanye sokutshiza). Yahlulwe kakhulu kwindawo yokongeza i-flux, indawo yokufudumala, indawo ye-welding kunye nendawo yokupholisa, njengoko kubonisiwe kulo mfanekiso ulandelayo.

3. Umahluko ophambili phakathi kwe-wave soldering kunye ne-reflow welding

Umahluko omkhulu phakathi kwe-wave soldering kunye ne-reflow welding kukuba umthombo wokufudumeza kunye nendlela yokubonelela nge-solder kwi-welding yahlukile. Kwi-soldering wave, i-solder ifudumala kwangaphambili kwaye inyibilika kwitanki, kwaye i-solder wave eveliswa yimpompo idlala indima emibini yomthombo wobushushu kunye nokubonelela nge-solder. Amaza atyhidiweyo e-solder afudumeza imingxunya, iipads, kunye nezikhonkwane zecandelo lePCB, ngelixa likwabonelela ngesoda efunekayo ukwenza amalungu e-solder. Kwi-soldering ye-reflow, i-solder (i-solder paste) inikezelwe kwangaphambili kwindawo ye-welding ye-PCB, kwaye indima yomthombo wokushisa ngexesha lokunyuka kwakhona kukunyibilikisa i-solder.

(1) I-3 Intshayelelo kwinkqubo yokukhetha i-wave soldering

Isixhobo sokuthengisa amaza senziwe iminyaka engaphezu kwama-50, kwaye ineengenelo zemveliso ephezulu esebenzayo kunye nemveliso enkulu ekuveliseni amacandelo omngxuma kunye neebhodi zesekethe, ngoko ke yayikhe yayisesona sixhobo sibalulekileyo sokuwelda kwimveliso ezenzekelayo yobuninzi. iimveliso zombane. Nangona kunjalo, kukho imida ekusebenziseni kwayo: (1) iiparamitha ze-welding zahlukile.

Amalungu ahlukeneyo e-solder kwibhodi yesekethe enye anokufuna iiparitha ze-welding ezahlukileyo kakhulu ngenxa yeempawu zazo ezahlukeneyo (ezifana nomthamo wobushushu, isithuba se-pin, iimfuno zokungena kwe-tin, njl.). Nangona kunjalo, uphawu lwe-solder ye-wave kukugqiba ukuwelda kwawo onke amalungu e-solder kuyo yonke ibhodi yesekethe phantsi kweeparamitha ezifanayo, ngoko ke iindawo ezahlukeneyo ze-solder kufuneka "zihlalise" enye kwenye, nto leyo eyenza ukuba i-wave soldering ibe nzima ngakumbi ukuhlangabezana ngokupheleleyo ne-welding. iimfuno zeebhodi zeesekethe ezikumgangatho ophezulu;

(2) Iindleko eziphezulu zokusebenza.

Ekusetyenzisweni okusebenzayo kwe-wave soldering yendabuko, yonke ipleyiti yokutshiza ye-flux kunye nokuveliswa kwe-tin slag kuzisa iindleko eziphezulu zokusebenza. Ingakumbi xa i-lead-free welding, kuba ixabiso le-lead-free solder lingaphezulu kwe-3 yamaxesha e-load solder, ukunyuka kweendleko zokusebenza okubangelwa yi-tin slag kuyamangalisa kakhulu. Ukongezelela, i-solder-free-free solder iyaqhubeka inyibilika ubhedu kwi-pad, kwaye ukubunjwa kwe-solder kwi-cylinder ye-tin kuya kutshintsha ngokuhamba kwexesha, okudinga ukongezwa rhoqo kwe-tin ecocekileyo kunye nesilivere ebiza kakhulu ukuyicombulula;

(3) Ingxaki yokugcinwa kunye nokugcinwa kwayo.

I-flux eseleyo kwimveliso iya kuhlala kwindlela yokuhanjiswa kwe-wave soldering, kunye ne-tin slag eyenziwe kufuneka isuswe rhoqo, ezisa ukugcinwa kwezixhobo ezinzima kunye nomsebenzi wokulondoloza kumsebenzisi; Ngenxa yezo zizathu, kwabakho ukuthengiswa kwamaza okukhethiweyo.

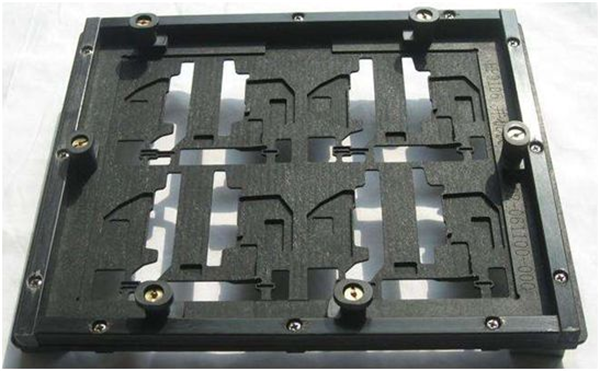

Okubizwa ngokuba yi-PCBA ekhethiweyo ye-wave soldering isasebenzisa iziko lokuqala letoti, kodwa umahluko kukuba ibhodi kufuneka ibekwe kwi-carrier yetoti, nto leyo esihlala siyithetha malunga nokulungiswa kweziko, njengoko kubonisiwe kulo mfanekiso ungezantsi.

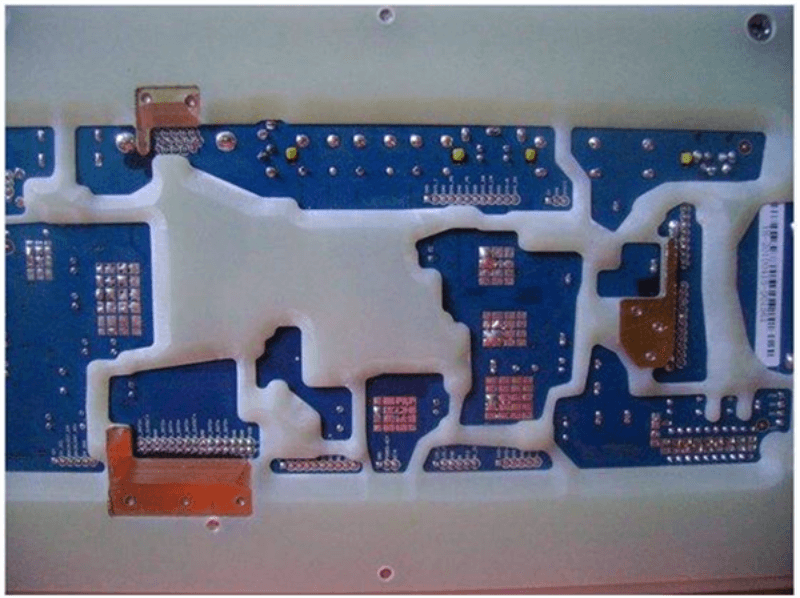

Amalungu afuna i-wave soldering afakwa kwitoti, kwaye amanye akhuselwe ngokugqunywa kwesithuthi, njengoko kubonisiwe ngezantsi. Oku kufana nokubeka i-buoy ebomini kwidama lokuqubha, indawo egqunywe li-life buoy ayizuwafumana manzi, kwaye endaweni yesitovu senkcenkce endaweni yayo, indawo egqunywe sisithuthi ngokwemvelo ayiyi kufumana tin, kwaye kuya kubakho. akukho ngxaki yokuphinda kunyibilike itoti okanye iindawo eziwayo.

"Ngenkqubo yeWelding yokubuyisela kwakhona umngxuma"

Nge-hole reflow welding yinkqubo ye-reflow welding yokufaka amacandelo, esetyenziswa kakhulu ekwenzeni iipleyiti zokudibanisa umphezulu eziqulethe iiplagi ezimbalwa. Ingundoqo yethekhnoloji yindlela yokusetyenziswa kwe-solder paste.

1. Intshayelelo yenkqubo

Ngokwendlela yesicelo se-solder paste, nge-welding ye-hole reflow inokwahlulwa ibe ziindidi ezintathu: ukuprintwa kombhobho ngokusebenzisa inkqubo ye-welding ye-solder, i-solder paste yoshicilelo ngenkqubo ye-welding ye-hole kunye ne-tin sheet exonxiweyo ngokusebenzisa inkqubo ye-welding.

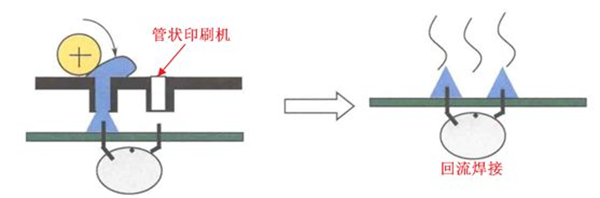

1) Ukuprintwa kweTubular ngokusebenzisa inkqubo ye-welding ye-hole reflow

Ushicilelo lweTubular ngenkqubo ye-welding ye-hole reflow sesona sicelo sakuqala senkqubo ye-welding ye-hole components reflow welding, esetyenziswa kakhulu ekwenzeni i-tuner ye-TV enemibala. Ingundoqo yenkqubo yi-solder paste press tubular, inkqubo iboniswe kumzobo ongezantsi.

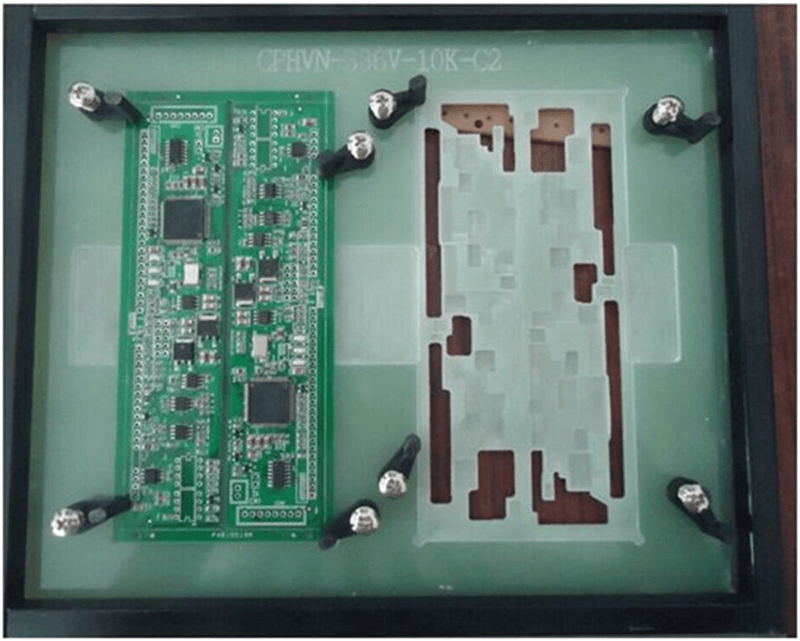

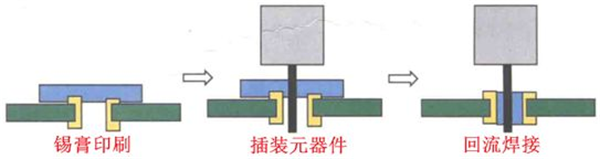

2) I-Solder paste yoshicilelo ngenkqubo ye-welding ye-hole reflow

I-Solder paste yoshicilelo ngenkqubo ye-welding ye-hole reflow iyeyona isetyenziswa kakhulu ngenkqubo ye-welding ye-hole reflow, isetyenziselwa ikakhulu kwi-PCBA edibeneyo equlethe inani elincinci le-plug-ins, inkqubo iyahambelana ngokupheleleyo nenkqubo ye-welding yesiqhelo, akukho zixhobo zenkqubo ekhethekileyo. efunekayo, imfuneko kuphela kukuba i-plug-in i-welded components kufuneka ifaneleke ngokusebenzisa i-hole reflow welding, inkqubo iboniswa kulo mfanekiso ulandelayo.

3) Ukubumba i-tin sheet ngokusebenzisa inkqubo ye-welding ye-hole reflow

Iphepha letoti elibunjiweyo ngenkqubo ye-welding ye-hole reflow isetyenziswa ikakhulu kwizihlanganisi ezininzi ze-pin, i-solder ayikho i-solder paste kodwa i-tin sheet ebunjiweyo, ngokubanzi ngumvelisi we-connector wongezwa ngokuthe ngqo, indibano inokufudunyezwa kuphela.

Ngokusebenzisa iimfuno zoyilo lokuhamba kwakhona komngxuma

Iimfuno zoyilo lwe-1.PCB

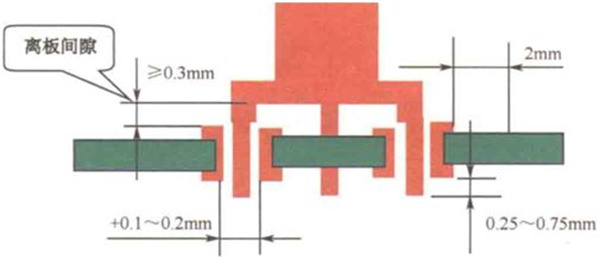

(1) Ifanele PCB ubukhulu ngaphantsi okanye ilingana 1.6mm ibhodi.

(2) Ububanzi obuncinane bepadi yi-0.25mm, kwaye intlama yesolder etyhidiweyo "itsalwa" kube kanye, kwaye intsimbi yenkcenkce ayibunjwa.

(3) Isikhewu secandelo elingaphandle kwebhodi (Ukumiswa) kufuneka sibe sikhulu kune-0.3mm

(4) Ubude obufanelekileyo belothe ephuma kwipad yi-0.25 ~ 0.75mm.

(5) Owona mgama usezantsi phakathi kwamacandelo esithuba esifana ne-0603 kunye ne-pad yi-2mm.

(6) Ukuvulwa okukhulu kwe-mesh yensimbi kunokwandiswa nge-1.5mm.

(7)Imbobo yidayamitha yelothe kunye ne-0.1 ~ 0.2mm. Njengoko kubonisiwe kumfanekiso olandelayo.

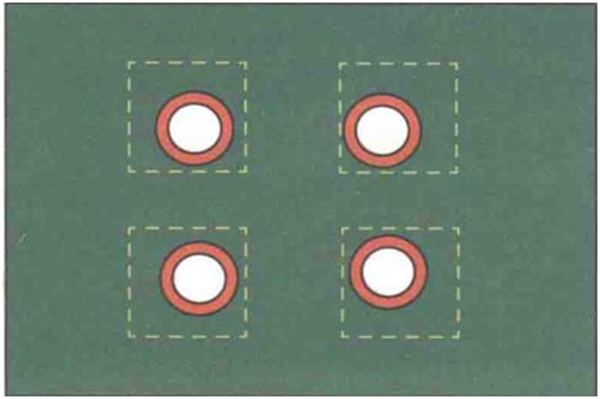

"Iimfuno zokuvula ifestile yentsimbi enemesh"

Ngokubanzi, ukuze ufezekise i-50% yokuzaliswa komngxuma, i-window ye-mesh yensimbi kufuneka yandiswe, inani elithile lokwandiswa kwangaphandle kufuneka ligqitywe ngokuhambelana nobukhulu be-PCB, ubukhulu be-mesh yensimbi, i-gap phakathi komngxuma kunye nokukhokela. kunye nezinye izinto.

Ngokubanzi, nje ukuba ukwandiswa akudluli kwi-2mm, i-solder paste iya kutsalwa ngasemva kwaye izaliswe emngxunyeni. Kufuneka kuqatshelwe ukuba ukwandiswa kwangaphandle akunakunyanzeliswa yipakethe yecandelo, okanye kufuneka kuphephe umzimba wepakethe yecandelo, kwaye wenze i-tin bead kwelinye icala, njengoko kuboniswe kulo mfanekiso ulandelayo.

"Intshayelelo kwiNkqubo yeNdibano eqhelekileyo yePCBA"

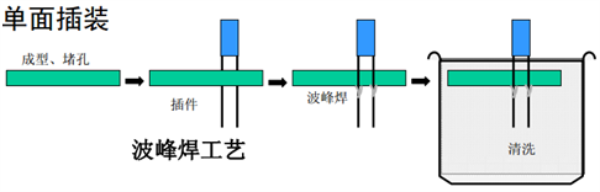

1) Ukunyuswa kwecala elinye

Ukuhamba kwenkqubo kuboniswe kumzobo ongezantsi

2) Ukufakwa kwecala elinye

Ukuhamba kwenkqubo kuboniswe kuMfanekiso 5 ngezantsi

Ukuqulunqwa kwezikhonkwane zesixhobo kwi-soldering wave yenye yezona ndawo zincinci zenkqubo yemveliso, ehambelanayo izisa umngcipheko womonakalo we-electrostatic kunye nokwandisa ixesha lokunikezelwa, kwaye kwandisa ithuba lempazamo.

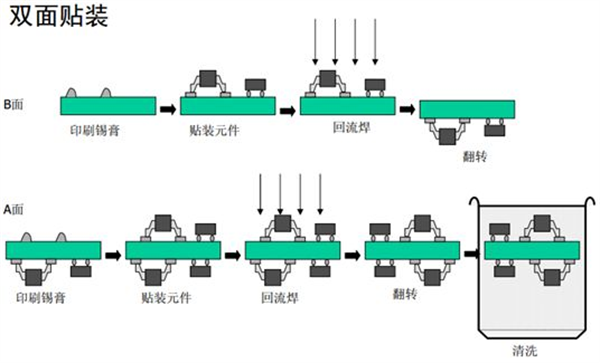

3) Ukuxhonywa kwamacala amabini

Ukuhamba kwenkqubo kuboniswe kumzobo ongezantsi

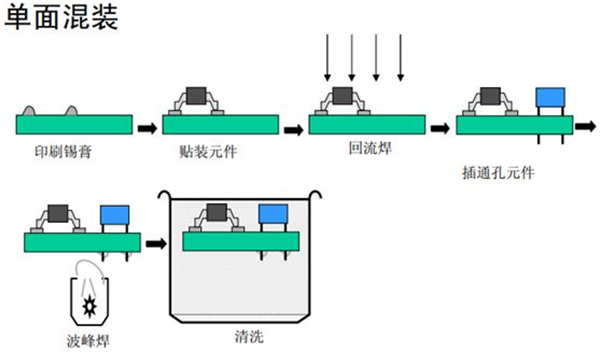

4) Icala elinye lixutywe

Ukuhamba kwenkqubo kuboniswe kumzobo ongezantsi

Ukuba kukho amacandelo ambalwa aphuma emngxunyeni, i-reflow welding kunye ne-welding manual ingasetyenziswa.

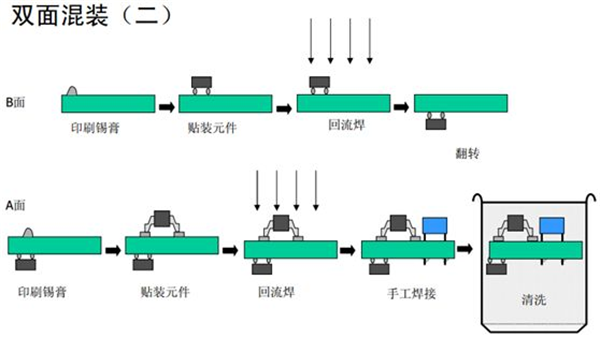

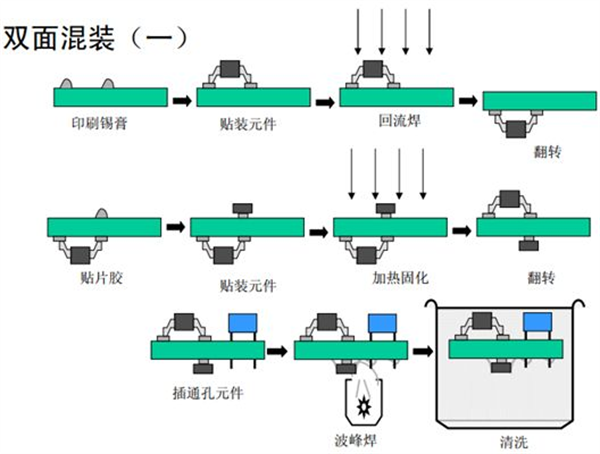

5) Ukuxuba okuphindwe kabini

Ukuhamba kwenkqubo kuboniswe kumzobo ongezantsi

Ukuba kukho izixhobo eziphindwe kabini ze-SMD kunye nezixhobo ezimbalwa ze-THT, izixhobo zeplagi zinokuphinda ziqhutyelwe okanye zifakwe ngesandla. Itshathi yenkqubo yokuqukuqela iboniswe ngezantsi.