【 Impahla eyomileyo 】 Uhlalutyo olunzulu lwe-SMT kutheni ukusebenzisa iglu ebomvu?(uHlelo lwe-Essence luka-2023), lufanelekile!

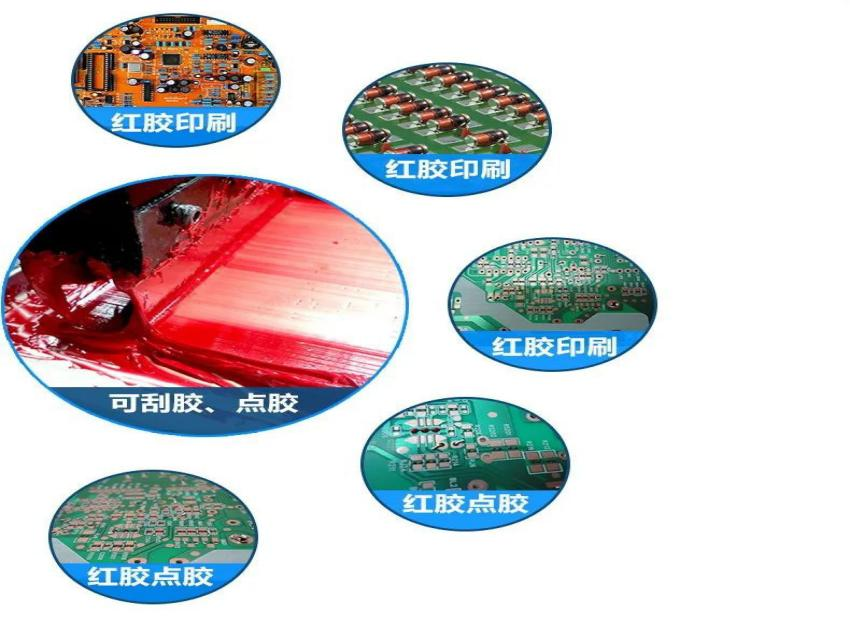

I-SMT encamathelayo, eyaziwa ngokuba yi-SMT adhesive, i-SMT encamathelayo ebomvu, idla ngokuba yintlama ebomvu (ekwayeyethubi okanye emhlophe) isasazwe ngokulinganayo nge-hardener, pigment, solvent kunye nezinye izinto ezincamathelayo, ikakhulu ezisetyenziselwa ukulungisa amacandelo kwibhodi yokushicilela, isasazwa ngokubanzi ngokusasazwa. okanye iindlela zokuprinta isikrini sentsimbi.Emva kokugxumeka amacandelo, zibeke kwi-oven okanye i-reflow furnace yokufudumala kunye nokuqina.Umahluko phakathi kwayo kunye ne-solder paste kukuba iphiliswa emva kokushisa, iqondo lokukhenkceza liyi-150 ° C, kwaye ayiyi kuchithwa emva kokuhlaziya, oko kukuthi, inkqubo yokuqina kobushushu bepatch ayinakuguqulwa.Ukusetyenziswa kwe-adhesive ye-SMT kuya kuhluka ngenxa yeemeko zokunyanga kwe-thermal, into edibeneyo, izixhobo ezisetyenzisiweyo, kunye nendawo yokusebenza.I-adhesive kufuneka ikhethwe ngokwenkqubo yebhodi yesekethe eprintiweyo (PCBA, PCA).

Iimpawu, ukusetyenziswa kunye nethemba le-SMT patch adhesive

Iglu ebomvu ye-SMT luhlobo lwe-polymer compound, amacandelo aphambili zizinto ezisisiseko (oko kukuthi, eyona nto iphezulu ye-molecular material), i-filler, i-ejenti yokunyanga, ezinye izongezo kunye nokunye.Iglu ebomvu ye-SMT ine-viscosity fluidity, iimpawu zobushushu, iimpawu zokumanzisa njalo njalo.Ngokwale mpawu yeglue ebomvu, kwimveliso, injongo yokusebenzisa iglue ebomvu kukukwenza iindawo zibambelele ngokuqinileyo kumphezulu wePCB ukuthintela ukuwa.Ke ngoko, i-adhesive patch kusetyenziso olusulungekileyo lweemveliso zenkqubo ezingabalulekanga, kwaye ngoku ngokuphuculwa okuqhubekayo koyilo lwePCA kunye nenkqubo, ngokuphinda umngxuma kunye ne-double-side-side reflow welding iye yafezekiswa, kunye nenkqubo yokunyuka kwe-PCA usebenzisa i-adhesive patch. ibonisa utyekelo lokuncipha.

Injongo yokusebenzisa i-SMT adhesive

① Thintela izixhobo ekubeni zingawi kwi-soldering ye-wave soldering.Xa usebenzisa i-soldering wave, amacandelo agxininiswe kwibhodi eprintiweyo ukukhusela amacandelo ukuba angawi xa ibhodi eprintiweyo idlula kwi-solder groove.

② Ukuthintela elinye icala lamacandelo ekuweni kwi-welding ye-reflow (inkqubo ye-welding ephindwe kabini).Kwinkqubo ye-welding ye-double-side-side reflow welding, ukwenzela ukukhusela izixhobo ezinkulu kwicala elithengisiweyo ukuba zingawi ngenxa yokuncibilika kobushushu be-solder, i-SMT patch glue kufuneka yenziwe.

③ Thintela ukufuduswa kunye nokuma kwamalungu (inkqubo ye-welding reflow, inkqubo yokwaleka kwangaphambili).Isetyenziswe kwiinkqubo ze-welding reflow kunye neenkqubo zokugubungela kwangaphambili ukukhusela ukufuduka kunye nokunyuka ngexesha lokunyuka.

④ Phawula (i-wave soldering, i-reflow welding, i-pre-coating).Ukongezelela, xa iibhodi eziprintiweyo kunye namacandelo aguqulwa kwiibhetshi, i-adhesive patch isetyenziselwa ukumakisha.

I-adhesive ye-SMT ihlelwa ngokwendlela yokusetyenziswa

a) Uhlobo lokukrala: ukulinganisa kuqhutyelwa ngokuprinta kunye nemodi yokukrazula ye-mesh yensimbi.Le ndlela yeyona isetyenziswa kakhulu kwaye inokusetyenziswa ngokuthe ngqo kwi-solder paste press.Imingxuma yentsimbi yentsimbi kufuneka imiselwe ngokohlobo lwamacandelo, ukusebenza kwe-substrate, ubukhulu kunye nobukhulu kunye nokuma kwemingxuma.Iinzuzo zayo zisantya esiphezulu, ukusebenza kakuhle kunye neendleko eziphantsi.

b) Uhlobo lokukhupha: Iglu isetyenziswe kwibhodi yesekethe eprintiweyo ngokukhupha izixhobo.Kufuneka izixhobo ezikhethekileyo zokuhambisa, kwaye ixabiso liphezulu.Izixhobo zokukhupha kukusetyenziswa komoya ocinezelweyo, iglu ebomvu ngentloko ekhethekileyo yokuhambisa kwi-substrate, ubungakanani bendawo yeglue, kangakanani, ngexesha, ubukhulu betyhubhu yoxinzelelo kunye nezinye iiparameters zokulawula, umatshini wokukhupha unomsebenzi oguquguqukayo. .Kwiindawo ezahlukeneyo, sinokusebenzisa iintloko ezihlukeneyo zokukhupha, ukubeka iiparitha zokutshintsha, unokutshintsha kwakhona imilo kunye nobuninzi benqaku leglue, ukuze ufezekise umphumo, iinzuzo zilungele, ziguquguquke kwaye zizinzile.Ukungalungi kulula ukuba nomzobo wocingo kunye namaqamza.Sinokuhlengahlengisa iiparamitha zokusebenza, isantya, ixesha, uxinzelelo lomoya, kunye nobushushu ukuze sinciphise ezi ntsilelo.

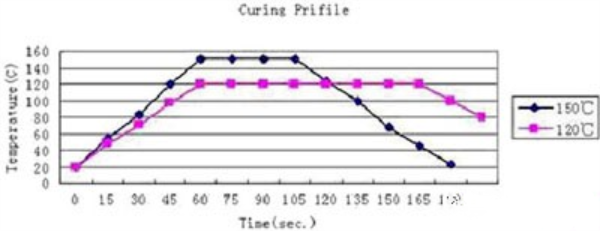

I-SMT patch incamathelisa iimeko eziqhelekileyo zokunyanga

| Ukunyanga ubushushu | Ixesha lokuphumla |

| 100℃ | 5 imizuzu |

| 120℃ | 150 imizuzwana |

| 150℃ | 60 imizuzwana |

Phawula:

I-1, iqondo lokushisa eliphezulu lokunyanga kunye nexesha elide lokunyanga, kokukhona ukomelela kokuqina.

I-2, ngenxa yokuba ukushisa kwe-adhesive patch kuya kutshintsha kunye nobukhulu beengxenye ze-substrate kunye nendawo yokunyuka, sincoma ukuba sifumane iimeko ezifanelekileyo zokuqina.

Ukugcinwa kweepetshi ze-SMT

Inokugcinwa iintsuku ezisi-7 kwiqondo lobushushu begumbi, ngaphezu kweenyanga ezi-6 ngaphantsi kwe-5 ° C, kwaye ngaphezu kweentsuku ezingama-30 kwi-5 ~ 25 ° C.

Ulawulo lokuncamathelisa kwe-SMT

Ngenxa yokuba iglue ebomvu ye-SMT ichaphazeleka bubushushu kunye ne-viscosity yayo, i-fluidity, ukumanzisa kunye nezinye iimpawu, ngoko i-SMT patch iglue ebomvu kufuneka ibe neemeko ezithile zokusetyenziswa kunye nolawulo olusemgangathweni.

1) Iglue ebomvu kufuneka ibe nenombolo ethile yokuhamba, ngokwenani lokutya, umhla, uhlobo kwinani.

2) Iglue ebomvu kufuneka igcinwe kwifriji kwi-2 ~ 8 ° C ukukhusela iimpawu ezichaphazelekayo ngenxa yokutshintsha kweqondo lokushisa.

I-3) Iglue ebomvu iyadingeka ukuba ifudumale kwiqondo lokushisa kweeyure ze-4, ngokulandelelana kokusetyenziswa kokuqala kokuqala.

I-4) Ngomsebenzi wokusabalalisa, i-glue ebomvu ye-hose kufuneka ihlanjululwe, kwaye iglue ebomvu engazange isetyenziswe kufuneka ibuyiselwe kwifriji yokugcina, kwaye i-glue endala kunye ne-glue entsha ayinakuxutywa.

I-5) Ukuzalisa ngokuchanekileyo ifom yerekhodi yokushisa yokubuyisela, ukubuyisela umntu weqondo lokushisa kunye nokubuyisela ixesha lokushisa, umsebenzisi kufuneka aqinisekise ukugqitywa kweqondo lokushisa lokubuyisela ngaphambi kokusetyenziswa.Ngokuqhelekileyo, iglue ebomvu ayikwazi ukusetyenziswa ngaphandle kwexesha.

Iimpawu zenkqubo ye-SMT patch adhesive

Amandla okudibanisa: Ukunamathela kwe-SMT kufuneka kube namandla okudibanisa okuqinileyo, emva kokuba lukhuni, nangona kwiqondo lokushisa elinyibilikayo le-solder alihliki.

Ukugquma amachaphaza: Okwangoku, indlela yokusasazwa kweebhodi eziprintiweyo ubukhulu becala kugquba amachaphaza, ngoko ke iglu iyafuneka ukuba ibe nezi zinto zilandelayo:

① Ukuqhelanisa neenkqubo ezahlukeneyo zokunyusela

Kulula ukuseta unikezelo lwecandelo ngalinye

③ Kulula ukuziqhelanisa nokutshintsha iindidi zecandelo

④ Isixa esizinzileyo sokugquma amachaphaza

Ukulungelelanisa kumatshini ohamba ngesantya esiphezulu: i-adhesive patch esetyenziswayo ngoku kufuneka idibane nesantya esiphezulu sendawo yokwaleka kunye nomatshini we-patch ohamba ngesantya esiphezulu, ngokukodwa, oko kukuthi, i-high-speed spot spotting ngaphandle komzobo wocingo, kwaye oko kukuthi, isantya esiphezulu. ukunyuka, ibhodi eprintiweyo kwinkqubo yokuhanjiswa, i-adhesive ukuqinisekisa ukuba amacandelo angahambi.

Umzobo wocingo, ukuwohloka: nje ukuba iglue incamathele kwipad, izixhobo azikwazi ukufikelela kunxibelelwano lombane kunye nebhodi eprintiweyo, ngoko ke iglu kufuneka ingabikho umzobo wocingo ngexesha lokwaleka, kungabikho kuwa emva kokugquma, ukuze ungangcolisi iphedi.

Ukunyanga ubushushu obuphantsi: Xa unyanga, izixhobo zeplagi ezikwazi ukumelana nobushushu ezidityaniswe ne-wave crest welding kufuneka ziphinde zidlule kwisithando somlilo se-reflow, ngoko ke iimeko zokuqina kufuneka zihlangabezane nobushushu obuphantsi kunye nexesha elifutshane.

Ukuzilungisa: Kwi-reflow welding kunye ne-pre-coating process, i-patch glue iyaphiliswa kwaye igxininiswe ngaphambi kokuba i-solder inyibilike, ngoko iya kuthintela icandelo ukuba lingatshoni kwi-solder kunye nokuzilungisa.Ukuphendula oku, abavelisi baye baphuhlisa isiqwenga sokuzilungisa.

SMT ancamathele iingxaki eziqhelekileyo, iziphene kunye nohlalutyo

ukucinezeleka

Imfuneko yamandla e-thrust ye-0603 capacitor yi-1.0KG, ukuxhathisa yi-1.5KG, amandla okuqhubela phambili kwe-0805 capacitor yi-1.5KG, ukuchasana yi-2.0KG, engakwazi ukufikelela ngasentla, ebonisa ukuba amandla awanele. .

Ibangwa ngokubanzi zezi zizathu zilandelayo:

I-1, isixa seglue akwanele.

2, i-colloid ayinyangeki i-100%.

3, ibhodi PCB okanye amacandelo zingcolisekile.

I-4, i-colloid ngokwayo i-brittle, akukho mandla.

Ukungazinzi Thixotropic

Iglue yesirinji ye-30ml idinga ukubethelwa amashumi amawaka amaxesha ngoxinzelelo lomoya ukuze isetyenziswe, ngoko ke iglue patch ngokwayo iyafuneka ukuba ibe ne-thixotropy egqwesileyo, kungenjalo iya kubangela ukungazinzi kwendawo yeglu, iglue encinci kakhulu, eya kukhokelela. ukungonelanga kwamandla, okubangela ukuba amacandelo awele ngexesha le-wave soldering, ngokuchaseneyo, inani leglue lininzi kakhulu, ngokukodwa kumacandelo amancinci, kulula ukunamathela kwi-pad, ukukhusela ukudibanisa kombane.

Iglu okanye indawo evuzayo eyaneleyo

Izizathu kunye namanyathelo okuThintela:

I-1, ibhodi yokushicilela ayicocwanga rhoqo, kufuneka ihlambuluke nge-ethanol rhoqo kwiiyure eziyi-8.

2, i-colloid inokungcola.

I-3, ukuvulwa kwebhodi ye-mesh kungenangqiqo kuncinci kakhulu okanye ukunyanzeliswa kwengcinezelo kuncinci, ukuyila kweglue eyaneleyo.

4, kukho amaqamza kwicolloid.

5. Ukuba intloko yokukhupha ivaliwe, umlomo wokukhupha kufuneka ucocwe ngokukhawuleza.

I-6, ukushisa kwangaphambili kwentloko yokukhupha akwanele, ubushushu bentloko yokukhupha kufuneka bubekwe kwi-38 ℃.

umzobo wocingo

Umzobo obizwa ngokuba ngumzobo wocingo yinto yokuba i-patch glue ayiphulwanga xa ihambisa, kwaye i-patch glue ixhunyiwe ngendlela ye-filamentous kwicala lentloko yokukhupha.Kukho iingcingo ezininzi, kwaye i-patch glue ihlanganiswe kwi-pad eprintiweyo, eya kubangela i-welding embi.Ngokukodwa xa ubukhulu bukhulu, le nto inokwenzeka ukuba yenzeke xa inqaku ligubungela umlomo.Umzobo we-patch glue uchaphazeleka kakhulu kwipropathi yomzobo wecandelo layo eliphambili le-resin kunye nokusekwa kweemeko zokwaleka kwamanqaku.

I-1, yandisa i-stroke yokukhupha, ukunciphisa isantya esihambayo, kodwa iya kunciphisa ukubetha kwakho kwemveliso.

I-2, i-viscosity ephantsi kakhulu, i-thixotropy ephezulu yezinto eziphathekayo, encinci ukuthambekela kokuzoba, ngoko zama ukukhetha i-adhesive patch.

I-3, iqondo lokushisa le-thermostat liphezulu kancinane, linyanzelekile ukuba lilungelelanise i-viscosity ephantsi, i-high thixotropic patch glue, emva koko uqwalasele ixesha lokugcinwa kwe-patch glue kunye noxinzelelo lwentloko ehambisayo.

emqolombeni

Ukunyibilika kwepetshi kuya kubangela ukudilika.Ingxaki eqhelekileyo yokuwa kukuba ukubeka ixesha elide emva kokugquma kwendawo kuya kubangela ukuwa.Ukuba i-glue ye-patch yandiswe kwi-pad yebhodi yesekethe eprintiweyo, iya kubangela i-welding embi.Kwaye ukuwa kwe-adhesive ye-patch yezo zixhobo ezinezikhonkwane eziphezulu, ayichukumisi umzimba oyintloko wecandelo, eliya kubangela ukunamathiswa okwaneleyo, ngoko ke izinga lokuwa kwe-patch ye-adhesive kulula ukudilika kunzima ukuqikelela, ngoko ke ukusetwa kokuqala komthamo wamachaphaza wayo nako kunzima.Ngenxa yoku, kufuneka sikhethe ezo akulula ukuwa, oko kukuthi, i-patch ephezulu kwisisombululo se-shake.Ukudilika okubangelwa ukubeka ixesha elide kakhulu emva kokugquma kwebala, sinokusebenzisa ixesha elifutshane emva kokugquma kwebala ukugqiba iglue ye-patch, ukunyanga ukuphepha.

Component offset

I-Component offset yinto engafunekiyo ekulula ukwenzeka koomatshini be-SMT abanesantya esiphezulu, kwaye ezona zizathu ziphambili zezi:

I-1, ibhodi eprintiweyo intshukumo yesantya esiphezulu sendlela ye-XY ebangelwa yi-offset, indawo yokugubungela i-adhesive patch yamacandelo amancinci athambekele kule nto, isizathu kukuba ukunamathela akubangelwa.

I-2, isixa seglue phantsi kwamacandelo asihambelani (njengokuthi: amanqaku amabini eglue phantsi kwe-IC, enye i-glue iphuzu likhulu kwaye i-glue iphuzu lincinci), amandla eglue ayilingani xa ishushu kwaye iphiliswa; kwaye isiphelo kunye neglue encinci kulula ukucima.

Ngokungaphezulu kwamaza okuthengisa iindawo

Izizathu zinzima:

1. I-adhesive force of patch ayikwanelanga.

2. Iye yachaphazeleka phambi kokuba i-wave soldering.

3. Kukho intsalela engaphezulu kwamanye amacandelo.

I-4, i-colloid ayimelani nefuthe eliphezulu lokushisa

Patch iglue umxube

Abavelisi abahlukeneyo be-patch glue ekubunjweni kweekhemikhali banomahluko omkhulu, ukusetyenziswa okuxubileyo kulula ukuvelisa ezininzi ezimbi: 1, ukuphilisa ubunzima;2, i-adhesive relay ayanelanga;3, ngaphezulu kwe-wave soldering off serious.

Isisombululo kukuba: ucoce ngokucokisekileyo ibhodi ye-mesh, i-scraper, i-dispensing kunye nezinye iindawo ekulula ukubangela ukuxuba, kwaye ugweme ukudibanisa iintlobo ezahlukeneyo ze-patch glue.