Ubudlelwane phakathi kwepleyiti yelaphu yePCB kunye ne-EMC

Isikhokelo: Ukuthetha ngobunzima bokutshintsha kombane, ingxaki yeplate yelaphu yePCB ayinzima kakhulu, kodwa ukuba ufuna ukuseta ibhodi yePCB elungileyo, umbane otshintshayo kufuneka ube ngomnye weengxaki (uyilo lwePCB alulungile, enokubangela ukuba kungakhathaliseki ukuba ulungisa njani umonakalo we-parameters i-debugging ilaphu.Oku akusiyo i-alarmist), kuba kukho izinto ezininzi eziqwalasela iibhodi zelaphu ze-PCB, ezifana nokusebenza kombane, umzila wenkqubo, iimfuno zokhuseleko, iziphumo ze-EMC, njl. Phakathi kwezinto, umbane ngowona usisiseko, kodwa i-EMC yeyona nto inzima ukuyiphatha.Inkqubela phambili yeeprojekthi ezininzi yingxaki ye-EMC.Eli nqaku liza kwabelana nawe ngobudlelwane phakathi kwebhodi yelaphu yePCB kunye ne-EMC ukusuka kwiindlela ezingama-22.

- Isekethe ephekiweyo inokwenza ngokuzolileyo isekethe ye-EMI yoyilo lwePCB

Impembelelo yesekethe engentla kwi-EMC inokucingelwa.Izihluzo zesiphelo segalelo zilapha;i-anti-strikes yoxinzelelo;ukuxhathisa i-R102 yempembelelo yangoku (kunye nelahleko yokunciphisa i-relay);I-Y capacitor ehluzwayo ngohluzo;i-fuse echaphazela ibhodi yoyilo lokhuseleko;sonke isixhobo apha sibaluleke kakhulu.Kuyimfuneko ukunambitha ngokucophelela imisebenzi kunye nemisebenzi yesixhobo ngasinye.Xa isekethe yoyilo iyilwe, inqanaba le-EMC elibukhali lizolile kwaye lizolile, njengokuseta amanqanaba amaninzi okucoca, inani kunye nendawo yenani le-Y capacitors.Ukhetho lobungakanani bovakalelo lombane lunxulumene ngokusondeleyo nemfuno yethu ye-EMC.Wamkele wonke umntu ukuba axoxe ngeesekethe ze-EMI ezibonakala zilula zecandelo ngalinye.

- I-2.I-Circuit kunye ne-EMC: (Eyona nto ixhaphakileyo i-anti-gravity topology, jonga ukuba zeziphi iindawo eziphambili kwisekethe equlethe indlela ye-EMC)

Amacandelo ambalwa esekethe kumzobo ongentla: impembelelo kwi-EMC ibaluleke kakhulu (qaphela ukuba inxalenye eluhlaza ayikho).Ngokomzekelo, wonke umntu uyazi ukuba i-radiation ye-electromagnetic field radiation yindawo, kodwa umgaqo osisiseko kukutshintsha kwemagnethi., Oko kukuthi, i-ring ring circuit ehambelanayo.

Ikhoyo ngoku inokuvelisa intsimi yamagnetic, evelisa umbane ozinzile kwaye ayikwazi ukuguqulwa kwindawo yombane.Intsimi yombane inokuvelisa imagnethi.Ke qiniseka ukuba ubeke ingqalelo kwezo ndawo zinesimo sokutshintsha, oko kukuthi, omnye wemithombo ye-EMC.Nantsi enye yomthombo we-EMC (enye yazo apha, ngokuqinisekileyo, kuya kubakho ezinye iinkalo kamva), njengesiphaluka somgca onamachaphaza kwisekethe, okukuvula ityhubhu yokutshintsha ukuvula ityhubhu.Isekhethi ye-turbine evaliweyo ayinakukwazi kuphela ukutshintshwa kwesantya sokutshintsha kunokulungelelanisa impembelelo kwi-EMC, kodwa indawo ye-cloth ye-routing circuit nayo inefuthe elibalulekileyo!Ezinye iilophu ezimbini zifunxa iringi kunye nesekethe yokulungisa, qala uqonde kwangaphambili, kwaye uthethe ngayo kamva.

- Okwesithathu, umanyano phakathi koyilo lwePCB kunye ne-EMC

1. Impembelelo ye-PCB loop kwi-EMC ibaluleke kakhulu.Umzekelo, i-anti-main power ring circuit, ukuba inkulu kakhulu, i-radiation iya kuba yimbi.

2. Isiphumo sokucoca i-wiring, isihluzo sisetyenziselwa ukucoca ukuphazamisa, kodwa ukuba i-PCB inocingo olubi, isihluzo sinokulahlekelwa umphumo.

3. Izakhiwo zesakhiwo, i-design-ground design ye-radiator iya kuchaphazela, inguqu ekhuselekileyo yomhlaba, njl.;

4. Indawo ebuthathaka isondele kakhulu kumthombo wokuphazamiseka.Ngokomzekelo, isekethe ye-EMI isondele kwi-tube yokutshintsha, eya kubangela ukuba i-EMC ihlupheke kwaye idinga indawo ecacileyo yodwa.

5. I-RC ifunxa isekethe.

6. I-Y capacitor isekelwe phantsi kunye ne-wiring, kwaye indawo ye-Y capacitor nayo ibalulekile.

Makhe sinike umzekelo omncinci ngezantsi:

Njengoko kuboniswe kumzobo kumfanekiso ongentla, i-X -capacitor pin routing icutshungulwa ngaphakathi.Unokufunda indlela yokwenza iplagi yokukhwela i-pink capacitor (usebenzisa i-extrusion current).Ngale ndlela, umphumo wokucoca we-X capacitor unokufikelela elona lizwe lihle.

- 4. Ukulungiselela uyilo lwePCB: (Ulungiselelo lwanele, luyilo kuphela olunokuthi luyilwe inyathelo ngenyathelo ukuphepha ukudilizwa koyilo)

Kukho imiba emalunga nale miba ilandelayo.Kucingelwa ukuba inkqubo yoyilo iya kuqwalaselwa.Wonke umxholo awunanto yakwenza nezinye izifundo.Sisishwankathelo nje samava ayo.

1. Ubungakanani besakhiwo sembonakalo, kubandakanywa imingxuma yokubeka, ukuhamba kwe-air duct, i-input and output sockets, kufuneka uhambelane nenkqubo yabathengi, kwaye kufuneka udibanise nomthengi, okhawulelwe phezulu.

2. Isiqinisekiso sokhuseleko, luhlobo luni lokuqinisekiswa kwemveliso, apho iindawo zenza i-insulation esisiseko kunye nokunyuka komgama, kunye nalapho ukomeleza ukugquma kwaye ushiye i-slot.

3. Uyilo lokupakisha: Ngaba kukho ixesha elikhethekileyo, elifana neendawo ezilungiselelwe ukulungiselela ukupakishwa.

4. Ukukhethwa kweendlela zenkqubo: Iphaneli enye-iphaneli yokhetho lwephaneli ephindwe kabini, okanye ibhodi enamanqwanqwa amaninzi, uvavanyo olubanzi ngokomzobo womgaqo kunye nobukhulu bebhodi, iindleko kunye nolunye uvavanyo olubanzi.

5. Ezinye iimfuno ezikhethekileyo kubathengi.

Ubugcisa bezakhiwo buya kuba bhetyebhetye ngokwentelekiso.Imimiselo yokhuseleko isalungiswa noko.Zeziphi izatifikethi, kwaye yeyiphi imigangatho yokhuseleko, ngokuqinisekileyo, kukho imimiselo yokhuseleko eqhelekileyo kwimigangatho emininzi, kodwa kukho nezinye iimveliso ezikhethekileyo ezifana nonyango lwezonyango.

Ukuze ukhazimle, izihlobo zenjineli entsha yenqanaba lokungena aziphazamisi.Nazi ezinye iimveliso eziqhelekileyo eziqhelekileyo.Oku kulandelayo ziimfuno ezithile zebhodi yelaphu ezishwankathelwa yi-IEC60065.Engqondweni imimiselo yokhuseleko, kufuneka ugcine engqondweni.Xa udibana neemveliso ezithile, kufuneka ujongane nazo:

1. Umgama weepads ze-fuse igalelo mkhulu kune-3.0mm.Ipleyiti yelaphu yokwenene iku-3.5mm (ukunyuka nje umgama wokunyuka kwamandla kwi-3.5mm phambi kwe-fuse, kwaye unyuke amandla kwi-3.0mm).

2. Imimiselo yokhuseleko ngaphambi nangemva kwebhulorho yokulungiswa kufuneka ibe yi-2.0mm, kunye nepleyiti yelaphu yi-2.5mm.

3. Emva kokulungiswa, imimiselo yokhuseleko ngokubanzi ayifuni iimfuno, kodwa igumbi lombane ophezulu kunye neliphantsi lishiywe ngokuhambelana nombane wangempela, kwaye umkhwa we-400V ungaphezulu kwe-2.0mm.

4. Imimiselo yokhuseleko kwinqanaba lokuqala yi-6.4mm (i-gap yombane), kwaye umgama wokunyuka ungcono ngokusekwe kwi-7.6mm (qaphela: oku kuhambelana nombane wegalelo langempela. vumela) .

5. Sebenzisa iindawo ezibandayo kwinqanaba lokuqala kwaye uchonge ngokucacileyo;L, N uchongo, igalelo AC Input logo, fuse isilumkiso logo, etc. zonke kufuneka imakishwe ngokucacileyo.

Wonke umntu uyathandabuza malunga noku kungasentla, unokuxoxa kwaye afunde omnye komnye.

Kwakhona, umgama wokhuseleko wokwenene unxulumene nombane wokufaka igalelo kunye nendawo yokusebenza.Ubalo oluthile lwetheyibhile luyafuneka.Idatha inikezelwe kwireferensi kuphela kwaye iziganeko ezichanekileyo zixhomekeke kwiimeko ezichanekileyo.

- 5. Imithetho yokhuseleko yoyilo lwePCB iqwalasela ezinye izinto

1. Qonda ukuba yintoni ukuqinisekiswa kweemveliso zakho, luhlobo luni lweemveliso, ezifana nonyango, unxibelelwano, umbane, iTV, njl., kodwa kukho iindawo ezininzi ezifanayo.

2. Indawo apho ukhuseleko lusondele kwibhodi yelaphu ye-PCB, qonda iimpawu zokugquma, ezizii-insulation ezisisiseko, eziphuculweyo zokugquma, kunye nemigama eyahlukeneyo yokugquma okusemgangathweni yahlukile.Kungcono ukujonga umgangatho, kwaye umgama wombane ubalwa kwaye umgama ukhuphuka.

3. Gxininisa kwisixhobo sokhuseleko semveliso, esifana nobudlelwane phakathi kwe-transformer magnetism kunye nesekela lomda wokuqala.

4. Ubushushu bokushisa kunye nomgama we-peripheral, umhlaba odibeneyo kwi-radiator uhlukile, umhlaba awufani, umhlaba usabanda, kunye nokufudumala komhlaba kuyafana.

5. Ingqwalasela ekhethekileyo kumgama we-inshurensi, eyona ndawo ingqongqo iyafuneka.Umgama phakathi kwefuse uyahambelana.

6. I-Y capacitor kunye nokuvuza kwangoku, qhagamshelana nobudlelwane bangoku.

Ukulandelela kuya kuchaza indlela yokugcina umgama kunye nendlela yokwenza iimfuno zokhuseleko.

- 6. Uyilo lwamandla loyilo lwePCB

1. Okokuqala, linganisa ubungakanani bePCB kunye nenani lezixhobo, ukwenzela ukuba kube lukhuni, ngaphandle koko kuqinile, kwaye kunzima ukubona iqhekeza le-sparseness.

2. Guqula isekethe, ugxininise kwizixhobo eziphambili, kunye nomgaqo wesixhobo esiphambili sokubeka isixhobo ngexesha elinye.

3. Isixhobo sithe nkqo okanye sithe tye.Enye intle, kwaye enye kukuququzelela imisebenzi yeplug-in.Iimeko ezikhethekileyo zinokuqwalaselwa.

4. Xa uyilo, kufuneka uqwalasele i-wiring kwaye uyibeke kwindawo efanelekileyo kakhulu kwaye uququzelele umgca wokulandelela.

5. Ngethuba lokucwangcisa, indawo yendandatho iyancitshiswa kangangoko kunokwenzeka, kwaye iindlela ezine ezinkulu zamakhonkco ziya kuchazwa ngokubanzi.

Ukufezekisa ezi ngongoma zingasentla, ngokuqinisekileyo, kuyimfuneko ukuyisebenzisa ngokuguquguqukayo, kwaye ulungelelwaniso olufanelekileyo luya kuzalwa kungekudala.

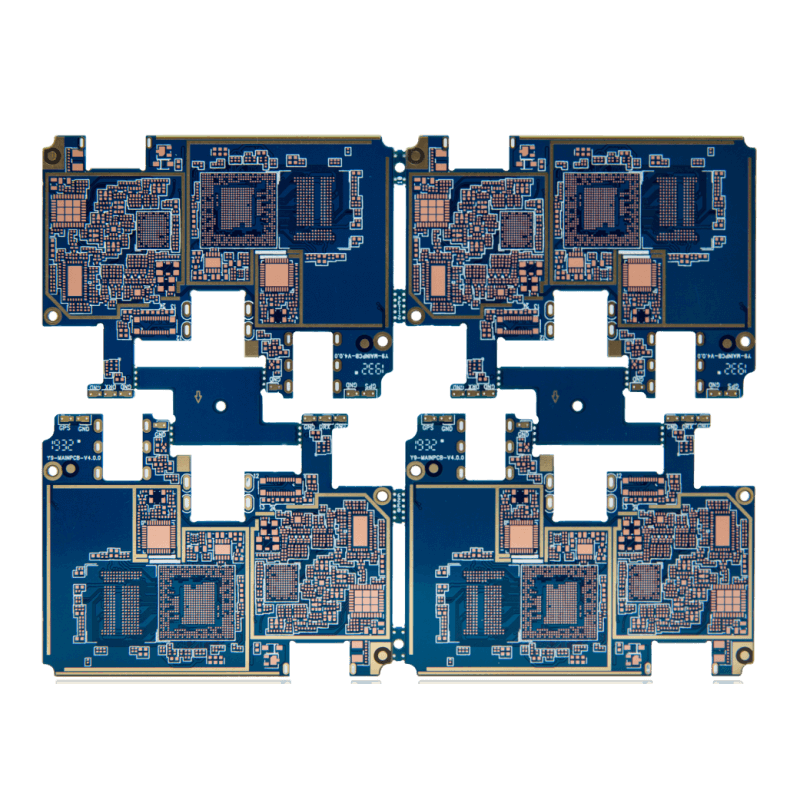

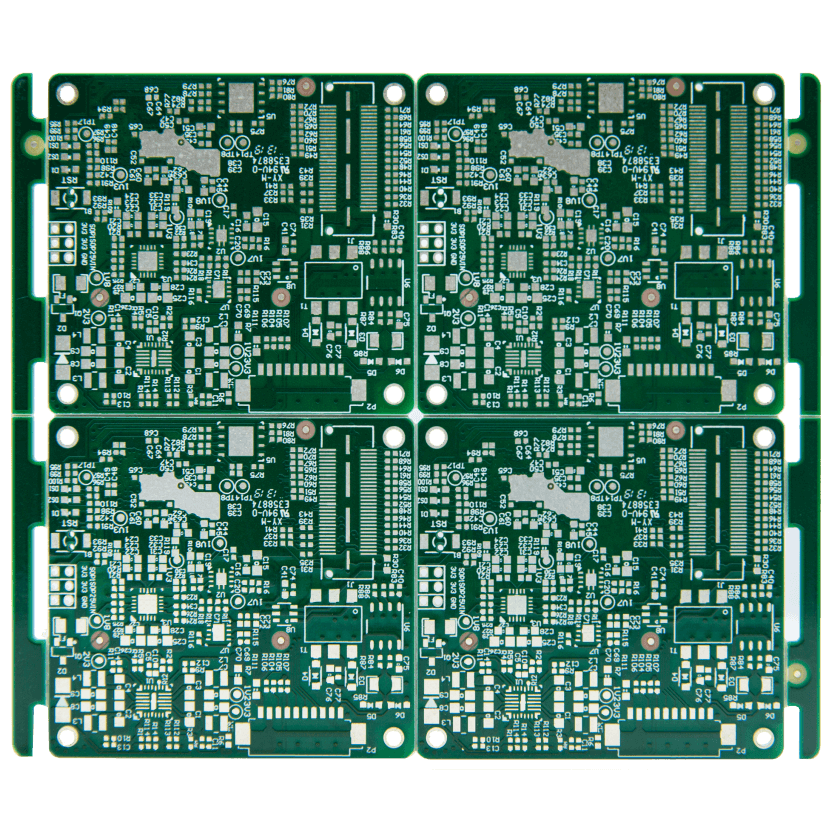

Oku kulandelayo yibhodi yePCB, ekufanele ukuba ifundwe kuyilo jikelele:

Ubuninzi bamandla beli nani busephezulu ngokwentelekiso.Phakathi kwabo, inxalenye yolawulo lwe-LLC, inxalenye yomthombo oncedisayo, kunye ne-BUCK i-circuit drive (i-high-power multi-road output) ikwibhodi encinci.

1. Iitheminali zegalelo kunye nemveliso zilungisiwe kwaye zifile.Ayikwazi ukushukuma.Ibhodi inoxande.Indlela yokukhetha ukuhamba kwamandla okuphambili?Apha, ukusuka ezantsi ukuya phezulu, ukusuka kwesobunxele nakwesokudla ukuya kwisakhiwo, ukutshatyalaliswa kobushushu kuxhomekeke kwigobolondo.

2. Isekethe ye-EMI isacacile.Oku kubaluleke kakhulu.Ukuba ibhidekile, ayilunganga kwi-EMC.

3. Isikhundla se-capacitors enkulu kufuneka sithathelwe ingqalelo kwi-PFC loop kunye neyona nto iphambili yamandla e-LLC.

4. Umjelo wecala lokuncedisa mkhulu.Ukuze kuthathwe i-current and heat dissipation of the rectifier pipe, le layout yamkelwa.Umbhobho wokulungisa uphezulu.nje.

Ibhodi nganye ineempawu zayo, kwaye ngokuqinisekileyo inobunzima bayo.Indlela yokusombulula ngokufanelekileyo ngundoqo.Ngaba uyayiqonda intsingiselo yokhetho olufanelekileyo loyilo?

- 7. PCB umzekelo ukuxabisa

Ngokutsho kobeko lwePCB ekuxoxwe ngalo ngaphambili, khangela le bhodi, nokuba isendaweni, ndicinga ukuba yindawo engcono.Kakade ke, iziphene ziya kuhlala zikhona.Unako kwakhona ukuyiphakamisa.Akukho lula, unokufunda kule bhodi!Kamva, uya kuchaza kwaye ufunde le bhodi.Masiyixabise kuqala.

- 8. Iindlela ezine zeringi ezinkulu zoyilo lwePCB (imfuno esisiseko yoyilo lwePCB yindawo encinci yeesekethe ezine zeringi ezinkulu)

Ukongeza, iringi yokufunxa (i-RCD yokufunxa kunye ne-RC yokufunxa ityhubhu ye-MOS, ukufunxwa kwe-RC kwemibhobho yokuhlaziya) nayo ibaluleke kakhulu, kwaye ikwayi-loop eyenza i-high-frequency radiation.Ukuba unayo nayiphi na imibuzo engentla, wamkelekile ukuba uyixoxe.Logama nje ibuzwa ngemibuzo, ukuxubusha kunye ukufunda kunokwenza inkqubela engakumbi!