Xa kuthelekiswa ne-silicon-based power semiconductors, i-SiC (i-silicon carbide) i-semiconductors yamandla ineenzuzo ezibalulekileyo ekutshintsheni ukuphindaphinda, ukulahlekelwa, ukuchithwa kobushushu, i-miniaturization, njl.

Ngemveliso enkulu yee-silicon carbide inverters nguTesla, iinkampani ezininzi ziqalisile ukwenza iimveliso ze-silicon carbide.

I-SiC "iyamangalisa", yenziwa njani emhlabeni? Zeziphi izicelo ngoku? Masibone!

01 ☆ Ukuzalwa kweSiC

Njengamanye ama-semiconductors amandla, ikhonkco leshishini le-SiC-MOSFET libandakanyai-crystal ende - i-substrate - i-epitaxy - ukuyila - imveliso - ikhonkco lokupakisha.

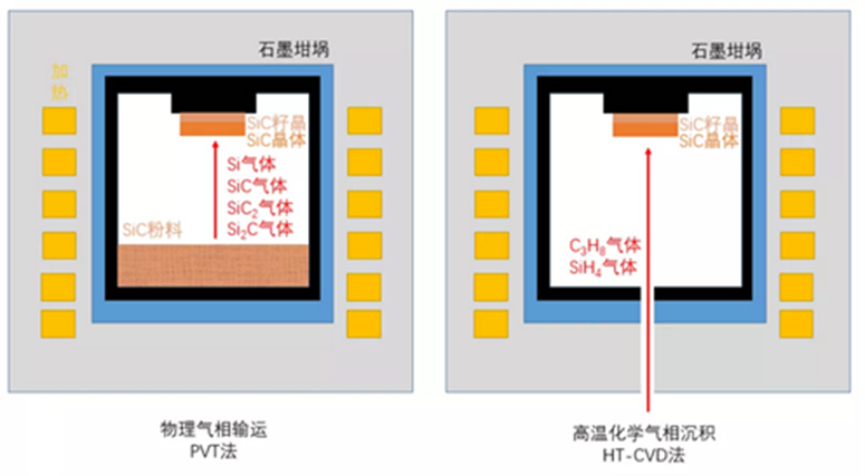

Ikristale ende

Ngexesha le-crystal link ende, ngokungafaniyo nokulungiswa kwendlela ye-Tira esetyenziswe yi-silicon eyodwa ye-crystal, i-silicon carbide ithatha kakhulu indlela yokuthutha igesi yomzimba (i-PVT, eyaziwa ngokuba yi-Lly ephuculweyo okanye indlela ye-crystal sublimation yembewu), indlela yokubeka igesi yekhemikhali ephezulu yokushisa (HTCVD) izongezelelo.

☆ Inyathelo eliphambili

1. Ikhabhoni eqinileyo imathiriyeli ekrwada;

2. Emva kokufudumeza, i-carbide eqinile iba yigesi;

3. Ukuhamba kwerhasi kumphezulu wekristale yembewu;

4. Irhasi ikhula kumphezulu wekristale yembewu ibe yikristale.

Umthombo wemifanekiso: "Inqaku lobuGcisa lokuqhaqha i-PVT yokukhula kwe-silicon carbide"

Ubuchwephesha obahlukileyo bubangele izinto ezimbi ezingalunganga xa kuthelekiswa nesiseko sesilicon:

Okokuqala, imveliso inzima kwaye isivuno siphantsi.Ubushushu besigaba segesi esekwe kwikhabhoni bukhula ngaphezulu kwe-2300 ° C kwaye uxinzelelo luyi-350MPa. Ibhokisi elimnyama elipheleleyo liqhutywa, kwaye kulula ukuxuba kwizinto ezingcolileyo. Isivuno sisezantsi kunesiseko se-silicon. Ubukhulu bedayamitha, isivuno sisezantsi.

Okwesibini kukukhula okucothayo.Ulawulo lwendlela ye-PVT icotha kakhulu, isantya si malunga ne-0.3-0.5mm / h, kwaye inokukhula nge-2cm kwiintsuku ze-7. Ubuninzi bunokukhula kuphela kwi-3-5cm, kwaye ububanzi be-crystal ingot ininzi i-intshi ezi-4 kunye ne-intshi ezi-6.

I-Silicon-based based 72H ingakhula ibe yi-2-3m ubude, kunye nobubanzi ubukhulu becala i-intshi ezi-6 kunye ne-8-intshi amandla okuvelisa amatsha angama-12 intshi.Ke ngoko, i-silicon carbide ihlala ibizwa ngokuba yi-crystal ingot, kwaye i-silicon iba yintonga yekristale.

Carbide silicon crystal ingots

ISubstrate

Emva kokuba i-crystal ende igqityiwe, ingena kwinkqubo yokuvelisa i-substrate.

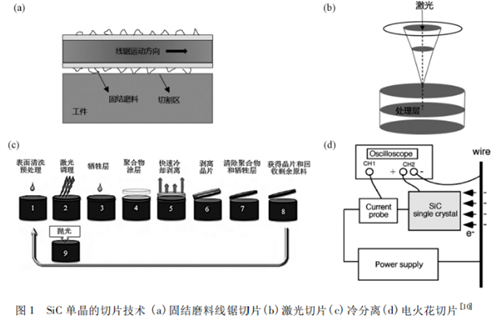

Emva kokusikwa okujoliswe kuyo, ukugaya (ukugaya ngokukrakra, ukugaya kakuhle), ukupholisa (i-mechanical polishing), i-ultra-precision polishing (ikhemikhali yokucoca i-mechanical polishing), i-silicon carbide substrate ifunyenwe.

I-substrate idlala ikakhuluindima yenkxaso yomzimba, i-thermal conductivity kunye ne-conductivity.Ubunzima bokucubungula kukuba impahla ye-silicon carbide iphezulu, i-crispy, kwaye izinzile kwiipropati zeekhemikhali. Ke ngoko, iindlela zemveli zokusetyenzwa kwe-silicon azifanelekanga kwi-silicon carbide substrate.

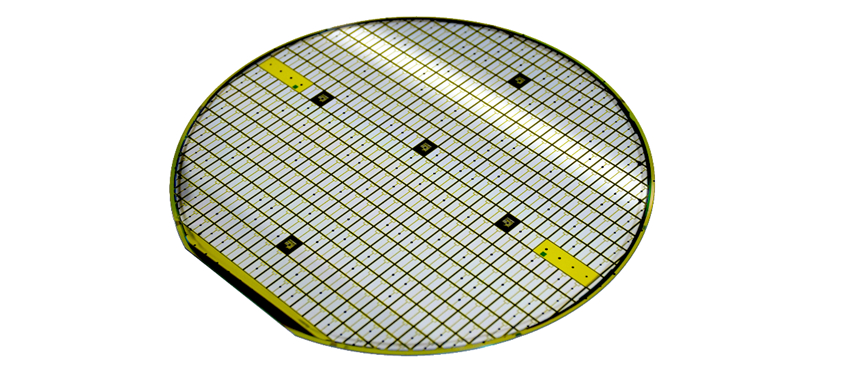

Umgangatho wesiphumo sokusika uchaphazela ngokuthe ngqo ukusebenza kunye nokusetyenziswa kakuhle (iindleko) zeemveliso ze-silicon carbide, ngoko ke kufuneka ukuba kuncinci, ubukhulu obufanayo kunye nokusika okuphantsi.

Ngoku,I-4-intshi kunye ne-6-intshi ikakhulu isebenzisa izixhobo zokusika zemigca emininzi,ukusika iikristale zesilicon zibe ziziqwenga ezibhityileyo ezinobunzima obungekho ngaphezulu kwe-1mm.

Idayagram yesicwangciso sokusika imigca emininzi

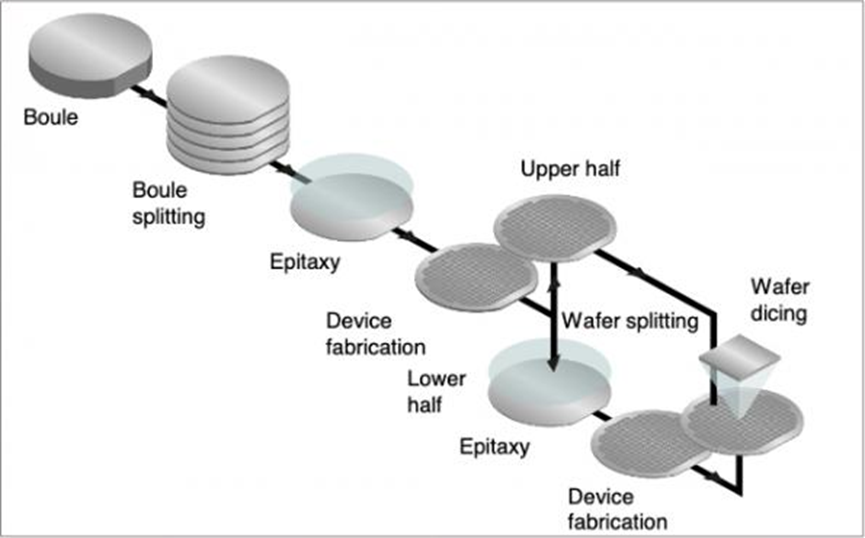

Kwixesha elizayo, ngokunyuka kobungakanani bama-wafers e-silicon, ukonyuka kweemfuno zokusetyenziswa kwezinto kuya kwanda, kwaye ubugcisa obufana nokunqunyulwa kwe-laser kunye nokwahlula okubandayo kuya kusetyenziswa ngokuthe ngcembe.

Ngo-2018, i-Infineon yafumana i-Siltectra GmbH, eyaphuhlisa inkqubo entsha eyaziwa ngokubanda okubandayo.

Xa kuthelekiswa nelahleko yenkqubo yokusika iintambo ezininzi ze-1/4,inkqubo yokuqhekeka ebandayo ilahlekelwe yi-1/8 yezinto ze-silicon carbide.

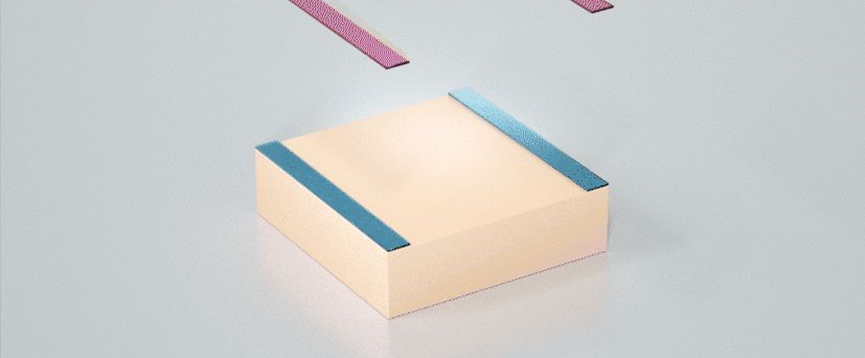

Ulwandiso

Ekubeni izinto ze-silicon carbide azikwazi ukwenza izixhobo zamandla ngokuthe ngqo kwi-substrate, izixhobo ezahlukeneyo ziyafuneka kwi-extension layer.

Ngoko ke, emva kokuba ukuveliswa kwe-substrate kugqityiwe, ifilimu ethile ye-crystal enye encinci ikhuliswe kwi-substrate ngokusebenzisa inkqubo yokwandisa.

Okwangoku, inkqubo ye-chemical gas deposition method (CVD) isetyenziswa kakhulu.

Yila

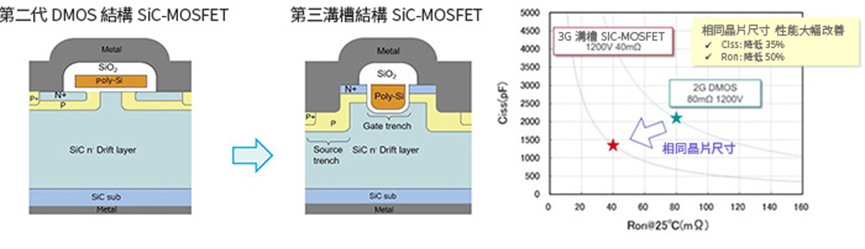

Emva kokuba i-substrate yenziwe, ingena kwinqanaba loyilo lwemveliso.

Kwi-MOSFET, ugqaliselo lwenkqubo yoyilo kuyilo lwegroove,kwelinye icala ukuphepha ukunyhashwa kwelungelo elilodwa lomenzi wechiza(I-Infineon, i-Rohm, i-ST, njl., i-patent layout), kwaye kwelinye icala ukuyaukuhlangabezana neendleko zokwenziwa kunye nokuvelisa.

Ukwenziwa kwe-wafer

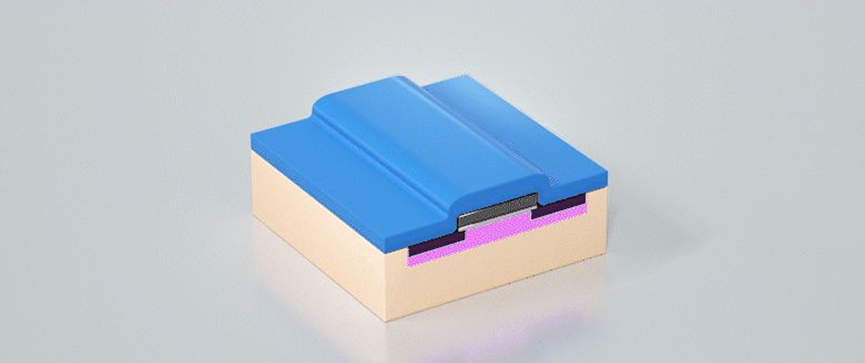

Emva kokuba uyilo lwemveliso lugqityiwe, lungena kwinqanaba lokuvelisa i-wafer,kwaye inkqubo iphantse ifane naleyo ye-silicon, eyona nto inama nyathelo ama-5 alandelayo.

☆Inyathelo loku-1: Tofa imaski

Uluhlu lwefilimu ye-silicon oxide (SiO2) yenziwe, i-photoresist ifakwe, iphethini ye-photoresist yenziwe ngamanyathelo e-homogenization, ukuvezwa, ukuphuhliswa, njl.

☆Inyathelo lesi-2: Ukufakelwa kwe-ion

I-silicon carbide wafer egqunyiweyo ifakwa kwisifakeli se-ion, apho iiyoni ze-aluminiyam zitofwa ukwenza indawo yedoping yodidi lwe-P, kwaye ifakwe i-annelled ukuze isebenze ii-ion ze-aluminiyam ezimiliselweyo.

Ifilimu ye-oxide isusiwe, i-ion ye-nitrogen ifakwe kwingingqi ethile ye-P-type doping region ukwenza i-N-type conductive region ye-drain kunye nomthombo, kunye ne-ion nitrogen emiliselweyo ifakwe kwi-annealed ukuze isebenze.

☆Inyathelo lesi-3: Yenza igridi

Yenza igridi. Kwindawo ephakathi komthombo kunye ne-drain, isango le-oxide yesango lilungiswe yinkqubo ye-oxidation yokushisa okuphezulu, kwaye i-electrode layer ifakwe kwisakhiwo sokulawula isango.

☆Inyathelo lesi-4: Ukwenza iileya zepassivation

Umaleko wokugqitha uyenziwa. Idiphozithi umaleko we-passivation oneempawu ezilungileyo zokugquma ukuthintela ukophuka kwe-interelectrode.

☆Inyathelo lesi-5: Yenza i-electrodes-source source

Yenza umsele kunye nomthombo. I-passivation layer i-perforated kwaye isinyithi sichithwa ukwenza umsele kunye nomthombo.

Umthombo wefoto: Xinxi Capital

Nangona kukho umahluko omncinci phakathi kwenqanaba lenkqubo kunye ne-silicon esekelwe, ngenxa yeempawu ze-silicon carbide materials,ukufakelwa kwe-ion kunye nokufakwa kwe-annealing kufuneka kuqhutywe kwindawo yobushushu obuphezulu(ukuya kwi-1600 ° C), ukushisa okuphezulu kuya kuchaphazela isakhiwo se-lattice sezinto ngokwazo, kwaye ubunzima buya kuchaphazela isivuno.

Ukongeza, kumacandelo e-MOSFET,umgangatho we-oksijini yesango ichaphazela ngokuthe ngqo ukuhamba kwesiteshi kunye nokuthembeka kwesango, kuba kukho iindidi ezimbini zesilicon kunye neeathom zekhabhoni kwizinto zesilicon carbide.

Ngoko ke, indlela ekhethekileyo yokukhula kwesango eliphakathi iyadingeka (enye ingongoma kukuba i-silicon carbide sheet ibonakala, kwaye ukulungelelaniswa kwendawo kwinqanaba le-photolithography kunzima kwi-silicon).

Emva kokuba ukuveliswa kwe-wafer kugqityiwe, itshiphu nganye iyasikwa ibe yitshiphu engenanto kwaye inokupakishwa ngokwenjongo. Inkqubo eqhelekileyo yezixhobo ezidityanisiweyo yi TO ipakethe.

I-650V CoolSiC™ MOSFETs kwi-TO-247 iphakheji

Ifoto: Infineon

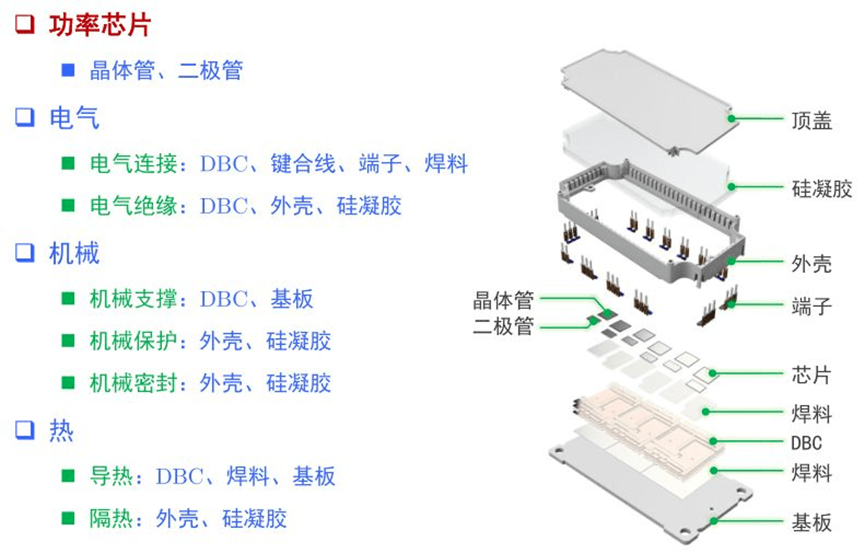

Intsimi yeemoto inamandla amakhulu kunye neemfuno zokutshatyalaliswa kobushushu, kwaye ngamanye amaxesha kuyimfuneko yokwakha ngokuthe ngqo iisekethe zebhulorho (isiqingatha sebhulorho okanye ibhuloho epheleleyo, okanye ihlanganiswe ngokuthe ngqo ngeediode).

Ke ngoko, ihlala ipakishwa ngokuthe ngqo kwiimodyuli okanye kwiinkqubo. Ngokwenani lee-chips ezifakwe kwimodyuli enye, ifom eqhelekileyo yi-1 kwi-1 (BorgWarner), i-6 kwi-1 (i-Infineon), njl., Kwaye ezinye iinkampani zisebenzisa i-single-tube parallel scheme.

Borgwarner Viper

Ixhasa ukupholisa kwamanzi amacala amabini kunye ne-SiC-MOSFET

Iimodyuli ze-Infineon CoolSiC™ MOSFET

Ngokungafaniyo nesilicon,iimodyuli ze-silicon carbide zisebenza kubushushu obuphezulu, malunga ne-200 ° C.

Iqondo lobushushu elithambileyo lemveli lokunyibilika lisezantsi, alikwazi ukuhlangabezana neemfuno zobushushu. Ke ngoko, iimodyuli ze-silicon carbide zihlala zisebenzisa inkqubo ye-welding yesilivere enobushushu obuphantsi.

Emva kokuba imodyuli igqityiwe, ingasetyenziswa kwinkqubo yamalungu.

Umlawuli wemoto yeTesla Model3

I-chip engenanto ivela kwi-ST, iphakheji eziphuhlisiwe kunye nenkqubo yokuqhuba umbane

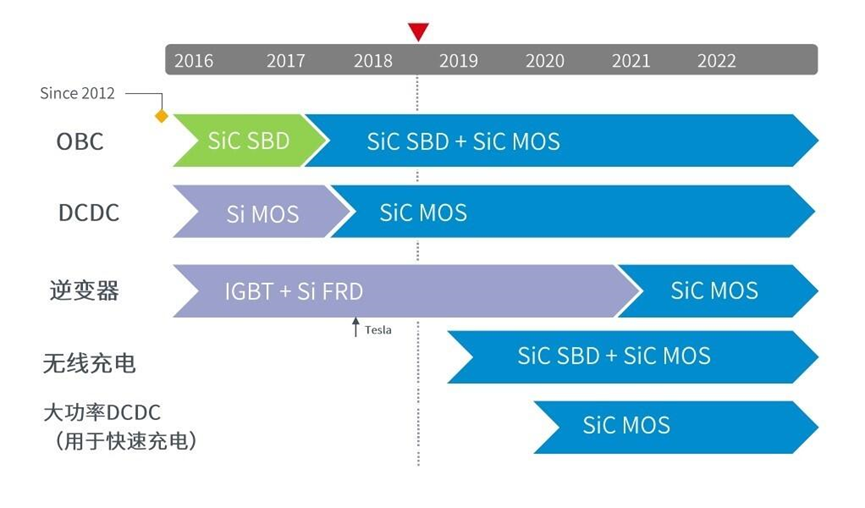

☆02 Ubume besicelo seSiC?

Kwintsimi yeemoto, izixhobo zombane zisetyenziswa kakhuluI-DCDC, i-OBC, ii-motor inverters, ii-inverters zombane zomoya, ukutshaja ngaphandle kwamacingo kunye nezinye iindawo.ezifuna ukuguqulwa ngokukhawuleza kwe-AC / DC (i-DCDC ikakhulu isebenza njengokutshintsha ngokukhawuleza).

Ifoto: BorgWarner

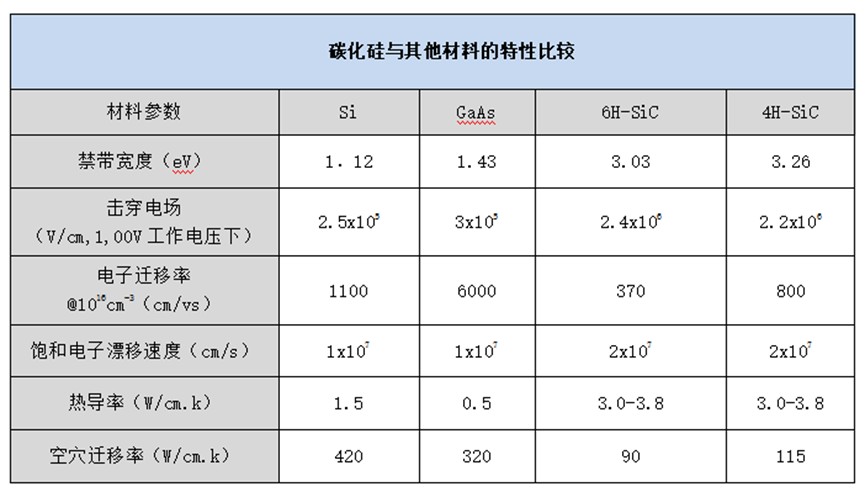

Xa kuthelekiswa nezinto ezisekwe kwi-silicon, izixhobo ze-SIC ziphezuluukomelela kwebala lokuqhekeka kwe-avalanche(3×106V/cm),ngcono thermal conductivity(49W/mK) kunyeumsantsa band ebanzi(3.26eV).

I-gap yebhendi ibanzi, incinci ukuvuza kwangoku kunye nokusebenza kakuhle. Eyona nto ingcono i-thermal conductivity, iphakamileyo yoxinaniso lwangoku. Okona kunamandla ibala elibalulekileyo lokuqhekeka kwe-avalanche kukuba, ukuxhathisa kombane wesixhobo kunokuphuculwa.

Ke ngoko, kwibala le-voltage ephezulu ebhodini, ii-MOSFETs kunye ne-SBD ezilungiselelwe yi-silicon carbide izinto zokutshintsha indawo ye-silicon-based IGBT kunye ne-FRD indibaniselwano inokuphucula ngokufanelekileyo amandla kunye nokusebenza kakuhle,ngakumbi kwiimeko zesicelo esiphezulu sokunciphisa ilahleko zokutshintsha.

Okwangoku, kunokwenzeka ukuba kuphunyezwe usetyenziso olukwinqanaba elikhulu kwii-motor inverters, zilandelwa yi-OBC kunye ne-DCDC.

Iqonga lombane le-800V

Kwiqonga lombane le-800V, iadvanteji yefrikhwensi ephezulu yenza amashishini athambekele ngakumbi ekukhetheni isisombululo se-SiC-MOSFET. Ke ngoko, uninzi lwe-800V yesicwangciso solawulo lwe-elektroniki sangoku iSiC-MOSFET.

Ucwangciso lwenqanaba leqonga lubandakanyaI-E-GMP yanamhlanje, i-GM Otenergy - indawo yokuthatha, i-Porsche PPE, kunye ne-Tesla EPA.Ngaphandle kweemodeli zeqonga lePorsche PPE ezingathwali ngokucacileyo iSiC-MOSFET (imodeli yokuqala yi-silica-based IGBT), amanye amaqonga ezithuthi amkela izikim zeSiC-MOSFET.

Iqonga lamandla e-Universal Ultra

Uyilo lwemodeli ye800V luninzi,iSalon enkulu yoDonga iJiagirong, iBeiqi pole Fox S HI version, imoto efanelekileyo iS01 kunye neW01, Xiaopeng G9, BMW NK1, Changan Avita E11 wathi uya kuthwala 800V iqonga, ukongeza BYD, Lantu, GAC 'an, Mercedes-Benz, zero Run, FAW Red Flag, Volkswagen kwakhona uthe 800V ubuchwepheshe kuphando.

Ukusuka kwimeko yee-odolo ze-800V ezifunyenwe ngababoneleli beTier1,BorgWarner, Wipai Technology, ZF, United Electronics, kunye neHuichuanzonke zibhengezwe ii-odolo zombane ze-800V.

Iqonga lombane le-400V

Kwiqonga lombane le-400V, i-SiC-MOSFET igxile ikakhulu ekuqwalaselweni kwamandla aphezulu kunye noxinano lwamandla kunye nokusebenza okuphezulu.

Njengemoto yeTesla 3\Y eveliswe ngobuninzi ngoku, amandla encopho ye-BYD Hanhou motor imalunga nama-200Kw (Tesla 202Kw, 194Kw, 220Kw, BYD 180Kw), i-NIO nayo iya kusebenzisa i-SiC-MOSFET yeemveliso eziqala ukusuka ku-ET5 kwaye ziya kufakwa kuluhlu lweET5. Amandla aphezulu ngama-240Kw (ET5 210Kw).

Ukongeza, ngokwembono yokusebenza ngempumelelo okuphezulu, amanye amashishini ajonga ukuba nokwenzeka kweemveliso ezincedisayo zeSiC-MOSFET.

Ixesha lokuposa: Jul-08-2023