Izizathu ze-SMT welding

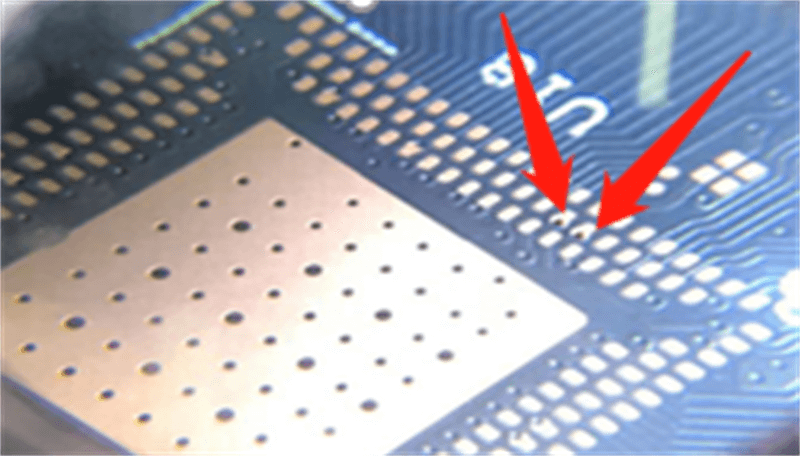

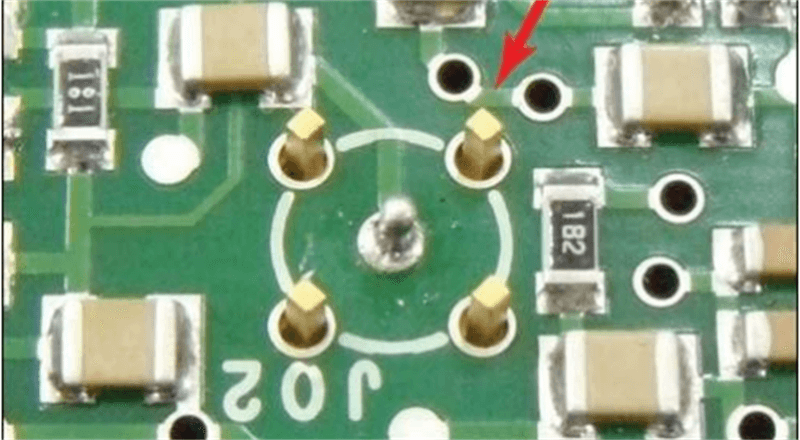

1. PCB iphedi uyilo iziphene

Kwinkqubo yoyilo lwe-PCB ethile, ngenxa yokuba isithuba sincinci ngokwentelekiso, umngxuma unokudlalwa kuphela kwiphedi, kodwa i-solder paste ine-fluidity, enokuthi ingene emngxunyeni, ibangele ukungabikho kwe-solder paste kwi-welding ye-reflow, ngoko xa isikhonkwane singonelanga ukutya i-tin, kuya kukhokelela kwi-welding virtual.

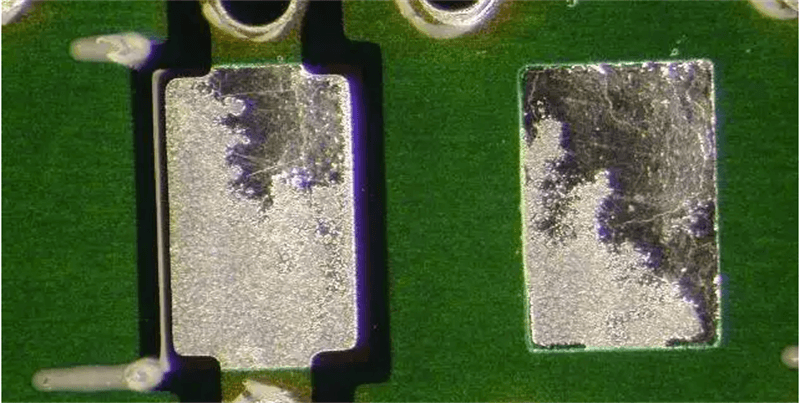

2.I-Pad surface oxidation

Emva kokuphinda kufakwe i-pad oxidized, i-welding ye-reflow iya kukhokelela kwi-welding ebonakalayo, ngoko xa i-pad i-oxidize, kufuneka yomiswe kuqala. Ukuba i-oxidation inzulu, kufuneka iyekwe.

Ukushisa kwe-3.Reflow okanye ixesha lobushushu bommandla ophezulu akwanele

Emva kokuba isiziba sigqityiwe, iqondo lobushushu alanelanga xa udlula kwindawo yokufudumeza i-reflow preheating zone kunye nommandla wobushushu obungaguqukiyo, nto leyo ekhokelela ekubeni enye inyibilika inyibilika itoni engazange yenzeke emva kokungena kwindawo yobushushu obuphezulu, okukhokelela ekutyeni okungonelanga kwetoti yephini yecandelo, okubangele ukuwelda okubonakalayo.

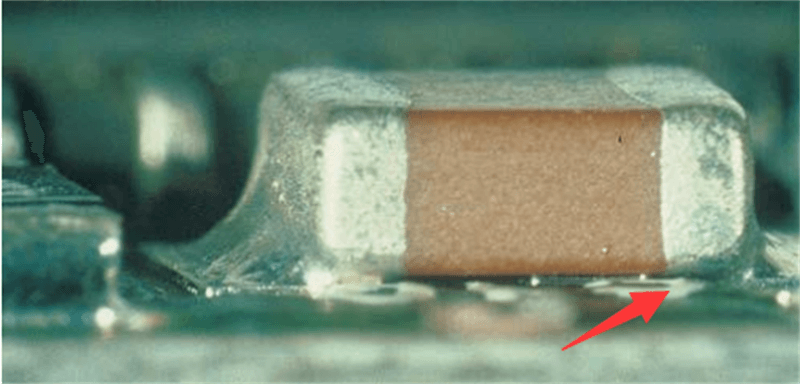

4.I-Solder yokuprinta i-paste ingaphantsi

Xa i-solder paste ihlanjululwa, inokuba ngenxa yokuvuleka okuncinci kwi-mesh yentsimbi kunye noxinzelelo olugqithisileyo lwe-scraper yokushicilela, okukhokelela ekushicileleni kwe-solder paste kunye nokuguquguquka okukhawulezileyo kwe-solder paste ye-welding reflow, ekhokelela kwi-welding virtual.

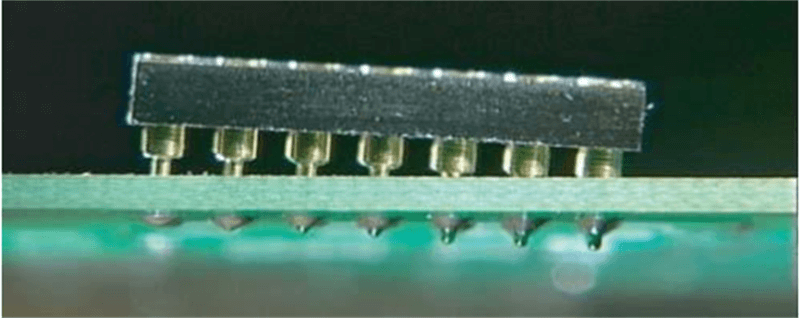

Izixhobo ze-5.High-pin

Xa isixhobo se-high-pin si-SMT, kusenokwenzeka ukuba ngenxa yesizathu esithile, icandelo likhubazekile, ibhodi ye-PCB igobile, okanye uxinzelelo olubi lomatshini wokubeka alunelanga, okubangela ukunyibilika okushushu okuhlukeneyo kwe-solder, okubangelwa ukuwelda okubonakalayo.

Izizathu ze-DIP ze-welding virtual

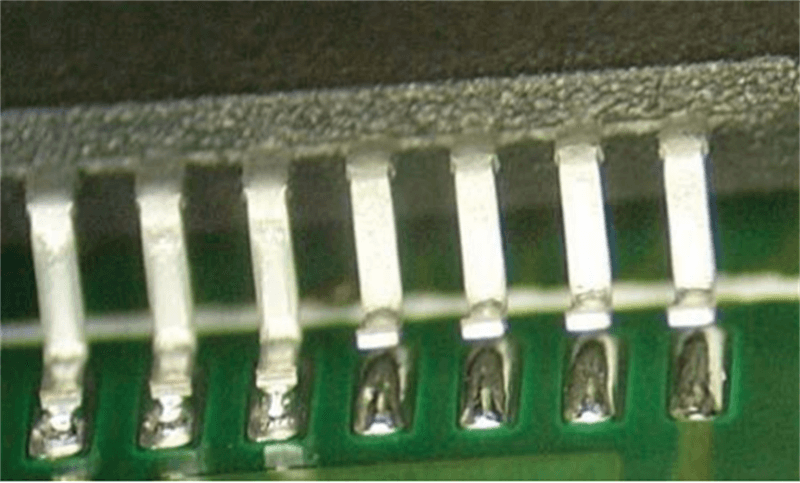

1.PCB plug-in umngxuma iziphene uyilo

I-PCB plug-in umngxuma, ukunyamezelana kuphakathi kwe-± 0.075mm, umngxuma wokupakisha we-PCB mkhulu kune-pin yesixhobo somzimba, isixhobo siya kuba sikhululekile, kubangele i-tin eyaneleyo, i-welding ebonakalayo okanye i-welding yomoya kunye nezinye iingxaki zomgangatho.

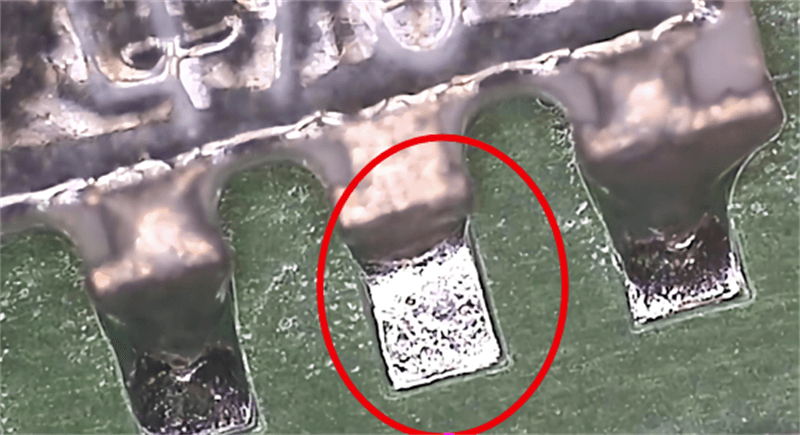

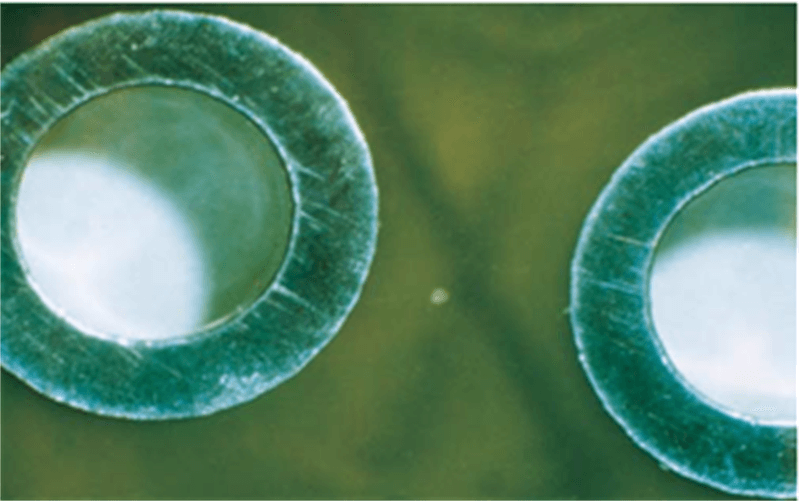

2.I-Pad kunye ne-oxidation yomngxuma

PCB imingxunya pad ayihlambulukanga, oxidized, okanye zingcoliswe izinto ezibiweyo, igrisi, amabala umbilo, njl, nto leyo eya kukhokelela weldability kakubi okanye non-weldability, okukhokelela ukuwelda virtual kunye nokuwelda emoyeni.

3.PCB ibhodi kunye nezinto umgangatho isixhobo

Iibhodi PCB ezithengiweyo, amacandelo kunye nezinye solderability ayifanelekanga, akukho uvavanyo engqongqo ukwamkelwa sele yenziwe, kwaye kukho iingxaki ezisemgangathweni ezifana ukuwelda virtual ngexesha indibano.

Ibhodi ye-4.PCB kunye nesixhobo siphelelwe lixesha

Iibhodi zePCB ezithengiweyo kunye namacandelo, ngenxa yexesha le-inventri lide kakhulu, elichatshazelwa yimeko yendawo yokugcina impahla, efana nobushushu, ukufuma okanye iigesi ezidliwayo, okukhokelela kwiziganeko ze-welding ezifana ne-welding virtual.

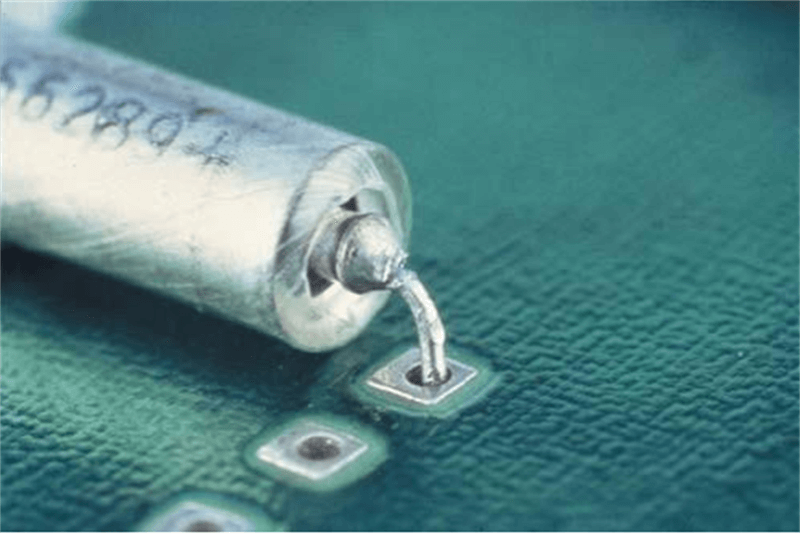

5.Wave izinto zokuthambisa izixhobo

Ubushushu obuphezulu kwisithando somlilo se-welding bukhokelela kwi-oxidation ekhawulezileyo yezinto ze-solder kunye nomphezulu wezinto ezisisiseko, okukhokelela ekunciphiseni ukunamathela komphezulu kwizinto eziphathekayo ze-solder. Ngaphezu koko, ubushushu obuphezulu buphinde budle umphezulu orhabaxa wesiseko, nto leyo ekhokelela ekuncitshisweni kwesenzo se-capillary kunye nokungasebenzi kakuhle, okukhokelela kwi-welding ebonakalayo.

Ixesha lokuposa: Jul-11-2023