1. Intshayelelo

Kwindibano yebhodi yesiphaluka, isolder paste iprintwa kuqala kwibhodi yesiphaluka solder pad, kuze emva koko kuncanyathiselwe izinto ezahlukeneyo ze-elektroniki. Ekugqibeleni, emva kwesithando somlilo, amaso e-tin kwi-solder paste ayanyibilika kwaye zonke iintlobo zamacandelo e-elektroniki kunye ne-solder pad yebhodi yesekethe ziyadityaniswa ukuze ziqonde ukuhlanganisana kwee-submodules zombane. i-surfacemounttechnology (sMT) isetyenziswa ngokunyukayo kwiimveliso zokupakisha ezixineneyo, njengepakethe yenqanaba lenkqubo (i-siP), izixhobo ze-ballgridarray (BGA), kunye ne-Chip engenamandla, i-square flat pin-less package (quad aatNo-lead, ebizwa ngokuba yi-QFN) isixhobo.

Ngenxa yeempawu zenkqubo yokuwelda uncamathisele kunye nezixhobo, emva kokuwelda kwezi zixhobo zinkulu zesolder, kuya kubakho imingxuma kwindawo yokuwelda, eya kuchaphazela iipropati zombane, iipropati ezishushu kunye neempawu zoomatshini zemveliso yoMsebenzi, kwaye zikhokelela ekungaphumeleli kwemveliso, ke ngoko, ukuphucula i-solder paste reflow welding welding iye yaba yinkqubo kunye nengxaki yobugcisa ekufuneka isonjululwe yi-balder yophando kunye nophando oluye lwasombululwa. i-welding cavity, kunye nezisombululo zokuphucula ezibonelelweyo, inkqubo ye-welding ye-solder yesiqhelo i-reflow ye-welding ye-QFN inkulu kune-10mm2 okanye indawo ye-welding enkulu kune-6 mm2 yesisombululo se-chip esingenanto.

Sebenzisa i-Preformsolder welding kunye ne-vacuum reflux ye-furnace welding ukuphucula umngxuma weld. I-solder eyenziwe ngaphambili idinga izixhobo ezikhethekileyo zokukhomba i-flux. Ngokomzekelo, i-chip ihlanjululwe kwaye ithotywe ngokukhawuleza emva kokuba i-chip ibekwe ngokuthe ngqo kwi-solder eyenziwe ngaphambili. Ukuba i-chip ye-flux ye-mount iphinda iphinde ibuyele kwaye ikhomba, inkqubo yongezwa ngokuphindaphindiweyo kabini, kunye neendleko ze-solder ezenziwe ngaphambili kunye nezinto ezixutywayo ziphezulu kakhulu kune-solder paste.

Izixhobo ze-vacuum reflux zibiza kakhulu, umthamo we-vacuum wegumbi elizimeleyo le-vacuum liphantsi kakhulu, iindleko zokusebenza azikho phezulu, kwaye ingxaki yokutshiza i-tin inzima, eyona nto ibalulekileyo ekusetyenzisweni kwemveliso ephezulu kunye ne-pitch encinci. Kweli phepha, ngokusekwe kwinkqubo yesiqhelo solder paste reflow welding, inkqubo entsha ye-welding welding entsha iphuhliswa kwaye yaziswa ukuze kuphuculwe i-welding cavity kunye nokusombulula iingxaki ze-bonding kunye ne-plastic seal cracking ebangelwa yi-welding cavity.

2 I-Solder paste yokushicilela i-reflow welding cavity kunye nendlela yokuvelisa

2.1 Umgqomo wokuwelda

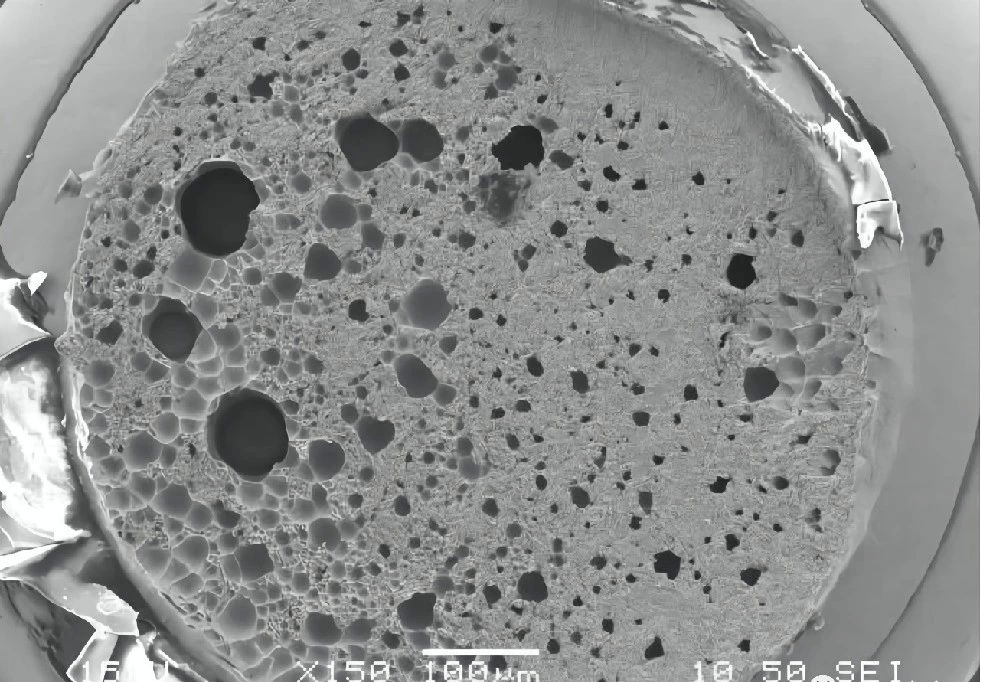

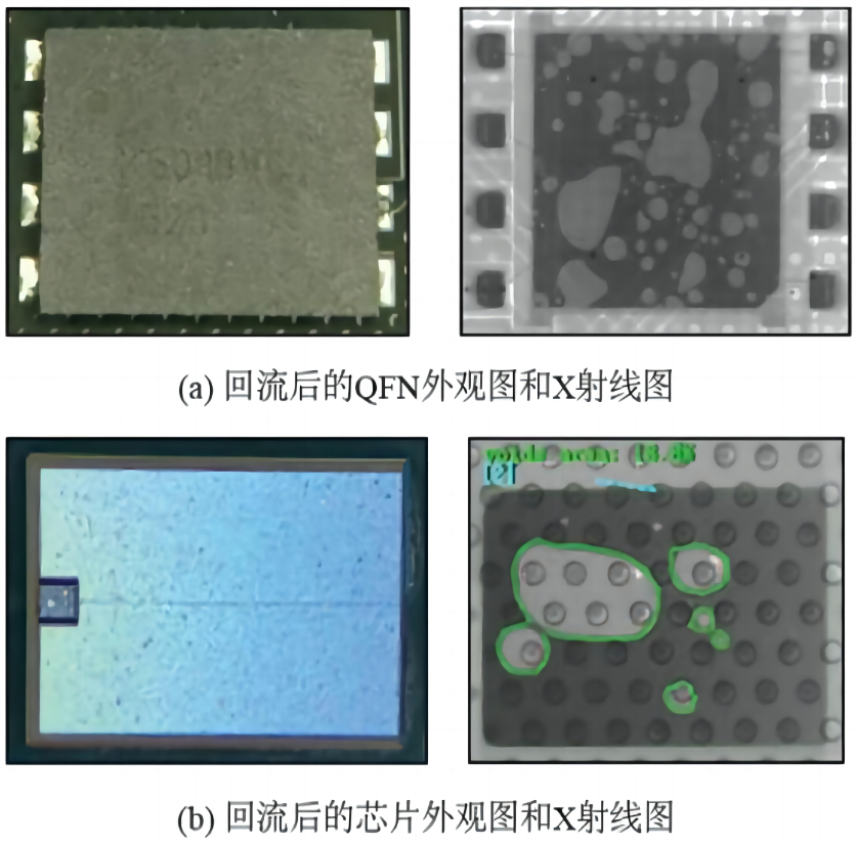

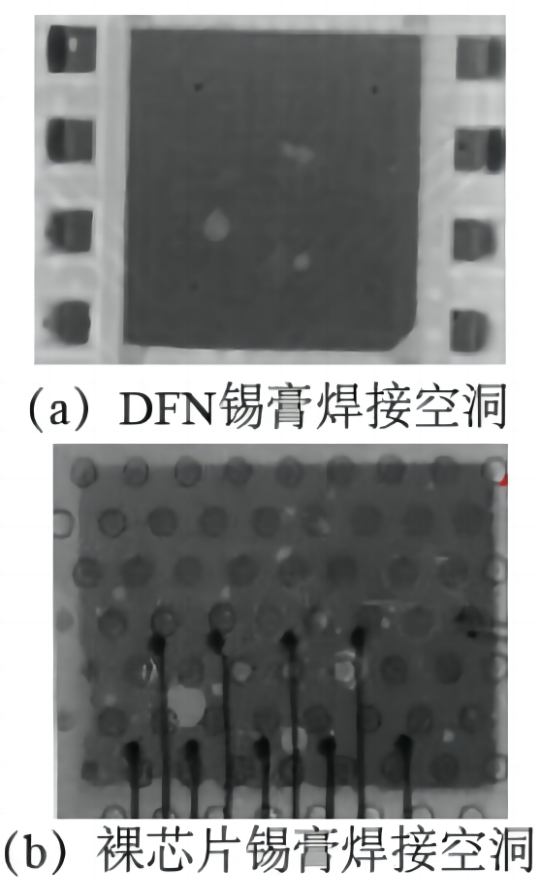

Emva kwe-welding ye-reflow, imveliso yavavanywa phantsi kwe-x-reyi. Imingxuma kwindawo ye-welding enombala okhanyayo ifunyenwe ngenxa yokungonelanga kwe-solder kwi-welding layer, njengoko kubonisiwe kuMfanekiso 1.

Ukufunyanwa kwe-X-ray yomngxuma weqamza

2.2 Indlela yokwenziwa kwe-welding cavity

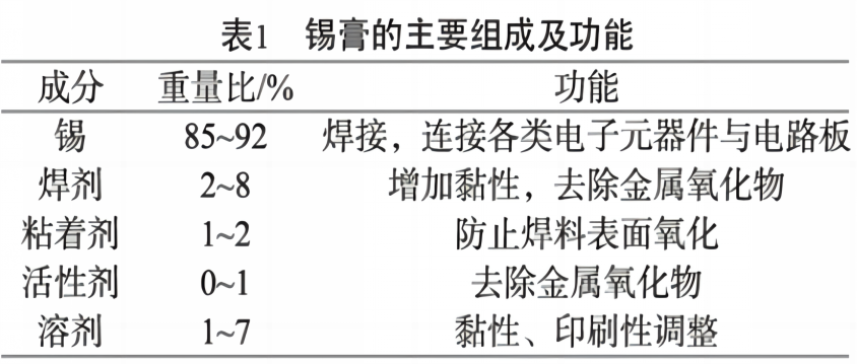

Ukuthatha i-sAC305 i-solder paste njengomzekelo, ukubunjwa okuphambili kunye nomsebenzi kuboniswe kwiThebhile 1. I-flux kunye ne-tin beads zidityaniswe kunye kwi-paste shape. Umlinganiselo wobunzima be-tin solder ukuya kwi-flux malunga ne-9: 1, kunye nomlinganiselo wevolumu malunga ne-1: 1.

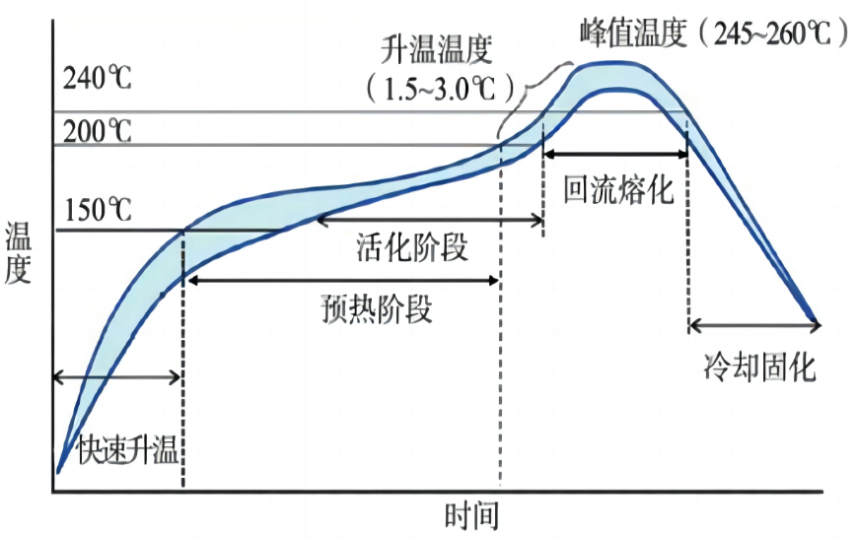

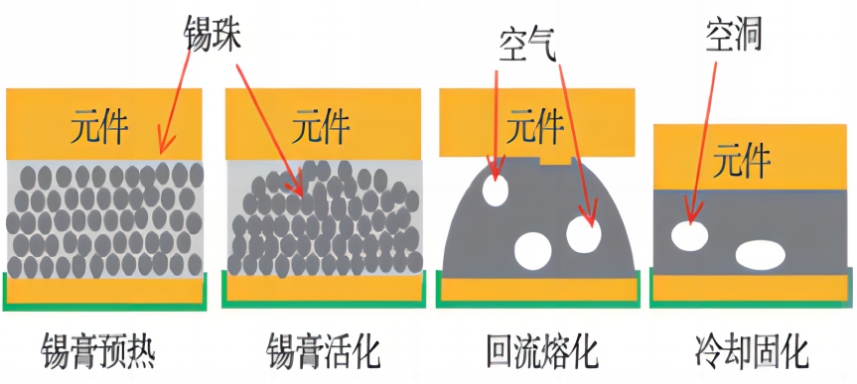

Emva kokuba i-solder paste ishicilelwe kwaye ifakwe ngamacandelo ahlukeneyo e-elektroniki, i-solder paste iya kudlula izigaba ezine zokufudumeza, ukuvuselela, i-reflux kunye nokupholisa xa idlula kwisithando somlilo se-reflux. Ubume be-solder paste bukwahluke ngamaqondo obushushu ahlukeneyo kwizigaba ezahlukeneyo, njengoko kubonisiwe kuMfanekiso 2.

Isalathiso seprofayili yendawo nganye ye-reflow soldering

Kwinqanaba lokufudumeza kunye nelokusebenza, amacandelo aguquguqukayo kwi-flux kwi-paste ye-solder iya kuguqulwa ibe yigesi xa ishushu. Ngelo xesha, iigesi ziya kuveliswa xa i-oxide ebusweni bomgca we-welding isusiwe. Ezinye zezi gesi ziya kuguquguquka kwaye zishiye i-solder paste, kwaye amaso e-solder aya kuqiniswa ngokuqinileyo ngenxa yokuguquka kwe-flux. Kwinqanaba le-reflux, i-flux eseleyo kwi-solder paste iya kuba ngumphunga ngokukhawuleza, amaso e-tin aya kunyibilika, umlinganiselo omncinci wegesi eguquguqukayo eguquguqukayo kwaye uninzi lomoya phakathi kwamaso e-tin awuyi kusasazwa ngexesha, kwaye intsalela kwitoti etyhidiweyo naphantsi koxinzelelo lwetoti etyhidiweyo iya kubanjwa, i-hamburger yesekethe kunye nebhodi ye-elektroniki iyabanjwa. isongelwe kwitoti yolwelo kunzima ukubaleka kuphela ngokunyuka okunyukayo. Ixesha lokunyibilika eliphezulu lifutshane kakhulu. Xa inkonkxa etyhidiweyo iphola kwaye ibe yinkcenkce eqinileyo, iipores zivela kwi-welding layer kwaye imingxuma ye-solder yenziwa, njengoko kubonisiwe kuMfanekiso 3.

Umzobo weSchematic of void oveliswa yi-solder paste reflow welding

Ingcambu ye-welding cavity kukuba umoya okanye igesi eguqukayo ehlanganiswe kwi-solder paste emva kokunyibilika ayikhutshwa ngokupheleleyo. Izinto eziphembelelayo ziquka izinto zokunamathisela i-solder, i-solder paste yokuprinta imilo, isixa sokushicilela i-solder paste, ubushushu be-reflux, ixesha le-reflux, ubungakanani be-welding, isakhiwo njalo njalo.

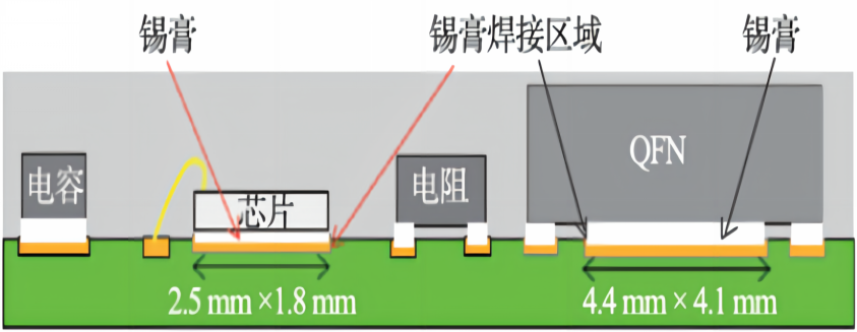

3. Ukuqinisekiswa kwezinto ezinempembelelo kwi-solder paste yokuprinta imingxuma ye-welding

I-QFN kunye neemvavanyo ze-chip ezingenalutho zazisetyenziselwa ukuqinisekisa izizathu eziphambili ze-reflow welding voids, kunye nokufumana iindlela zokuphucula i-reflow welding voids eprintwe yi-solder paste. I-QFN kunye ne-chip solder engenanto i-reflow iprofayili yemveliso ye-welding iboniswe kwi-Figure 4, ubukhulu be-welding ye-QFN yi-4.4mmx4.1mm, i-welding surface yi-tinned layer (100% yetoti ecocekileyo); Ubungakanani be-welding ye-chip engenanto yi-3.0mmx2.3mm, i-welding layer i-sputtered nickel-vanadium bimetallic layer, kunye ne-surface layer yi-vanadium. I-welding pad ye-substrate yayiyi-electroless nickel-palladium gold-dipping, kwaye ubukhulu be-0.4μm / 0.06μm / 0.04μm. I-SAC305 i-solder paste isetyenzisiweyo, izixhobo zokuprinta ze-solder ze-solder yi-DEK Horizon APix, izixhobo ze-reflux ze-furnace yi-BTUPyramax150N, kunye nezixhobo ze-x-ray yi-DAGExD7500VR.

I-QFN kunye nemizobo ye-welding ye-chip

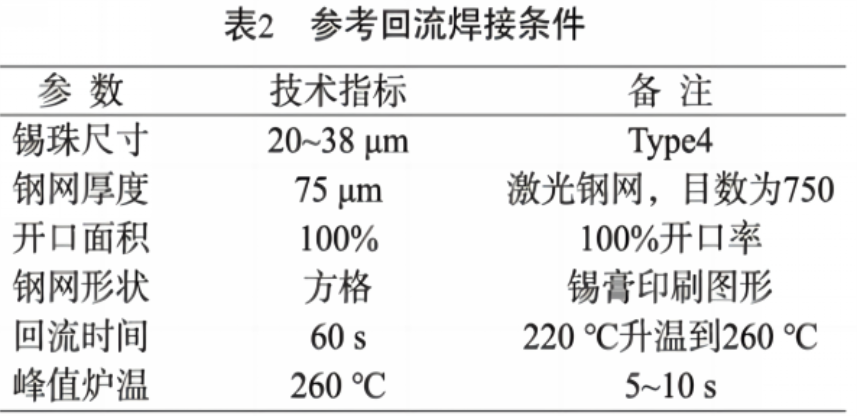

Ukuququzelela ukuthelekiswa kweziphumo zovavanyo, i-reflow welding yenziwa phantsi kweemeko kwiThebhile 2.

Reflow welding imeko itheyibhile

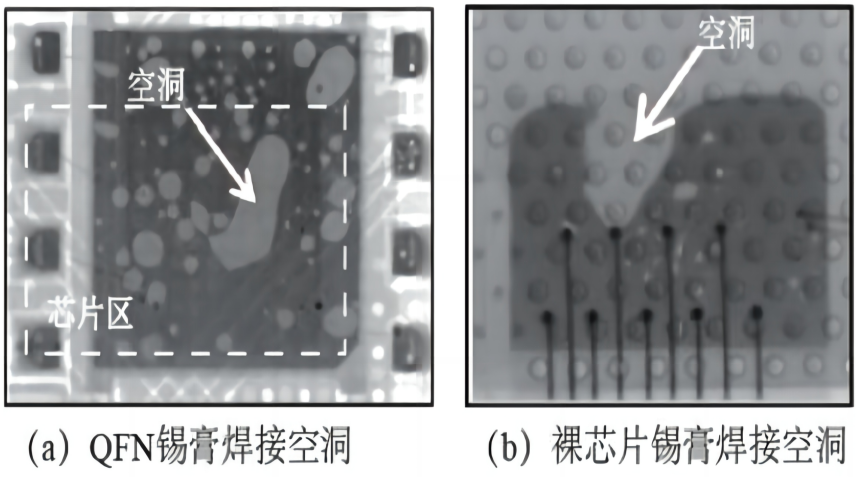

Emva kokunyuka komphezulu kunye ne-welding ye-reflow igqityiwe, i-welding layer yafunyanwa yi-X-ray, kwaye kwafunyaniswa ukuba kukho imingxuma emikhulu kwi-welding layer ephantsi kwe-QFN kunye ne-chip engenanto, njengoko kuboniswe kuMfanekiso 5.

I-QFN kunye ne-Chip Hologram (X-reyi)

Ekubeni ubukhulu be-tin bead, ubukhulu be-mesh yensimbi, izinga lokuvula indawo, i-mesh mesh shape, ixesha le-reflux kunye ne-peak ye-furnace yokushisa kuya kuchaphazela i-reflow welding voids, kukho izinto ezininzi ezichaphazelayo, eziya kuqinisekiswa ngokuthe ngqo ngovavanyo lwe-DOE, kwaye inani lamaqela okulinga liya kuba likhulu kakhulu. Kuyimfuneko ukuba ukhawuleze ukhuse kwaye umisele ezona zinto ziphambili ezinempembelelo ngovavanyo lothelekiso lothelekiso, kwaye emva koko uphucule ezona zinto ziphambili ezinempembelelo nge-DOE.

3.1 Imilinganiselo yemingxuma ye-solder kunye namaso etoti ye-solder

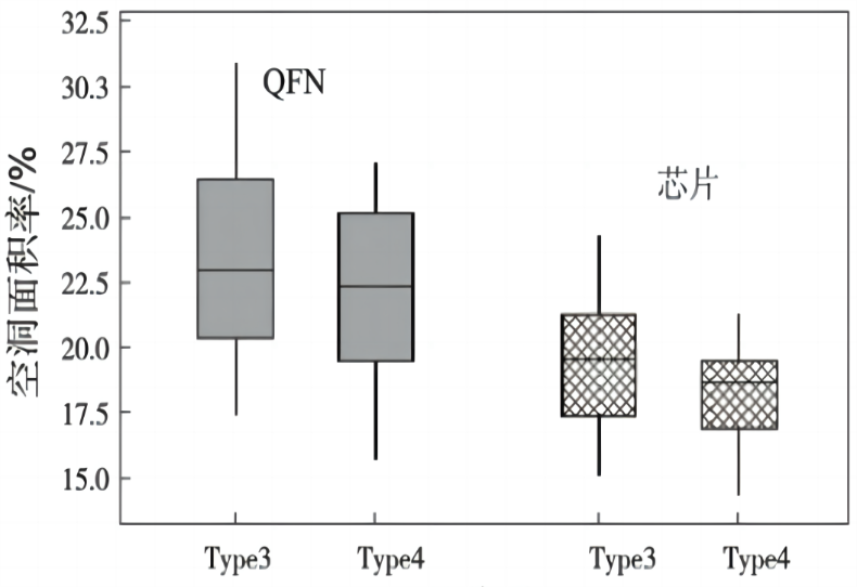

Ngohlobo lwe-3 (ubungakanani be-bead 25-45 μm) Uvavanyo lwe-SAC305 ye-solder paste, ezinye iimeko zihlala zingatshintshi. Emva kokuhamba kwakhona, imingxuma kwi-solder layer iyalinganiswa kwaye ithelekiswa ne-type4 ye-solder paste. Kufunyaniswa ukuba imingxuma kwi-solder layer ayahlukanga kakhulu phakathi kweentlobo ezimbini ze-solder paste, ebonisa ukuba i-solder paste enobungakanani obuhlukeneyo be-bead ayinayo impembelelo ecacileyo kwimingxuma kwi-solder layer, engeyiyo into enempembelelo, njengoko kubonisiwe kwi-FIG. 6 Njengoko kubonisiwe.

Ukuthelekiswa kwemingxuma yentsimbi ye-tin enobungakanani obuhlukeneyo

3.2 Ukutyeba komngxuma wokuwelda kunye nomnatha wentsimbi oprintiweyo

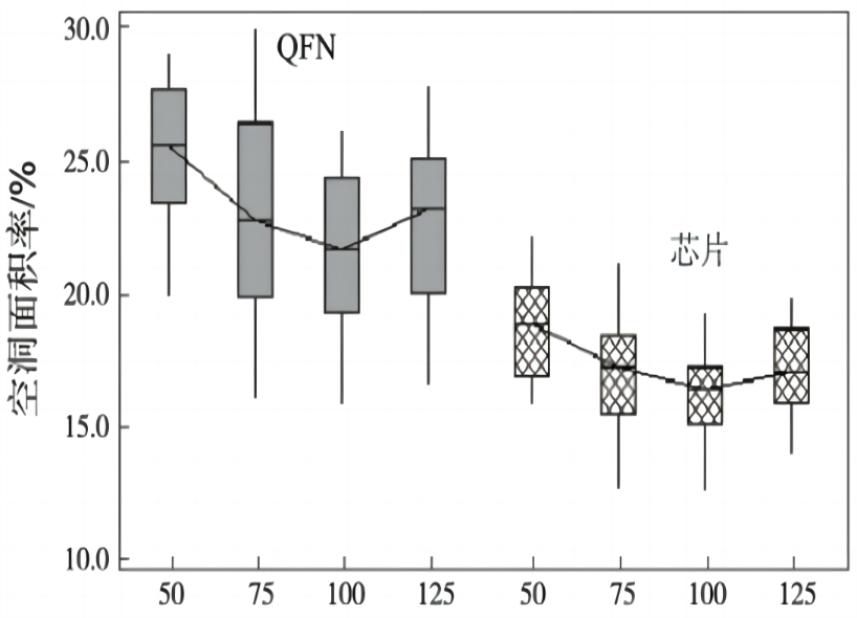

Emva kokuphindaphinda, ummandla we-cavity we-welded layer ulinganiswa kunye ne-mesh yensimbi eprintiweyo kunye nobukhulu be-50 μm, 100 μm kunye ne-125 μm, kunye nezinye iimeko zahlala zingatshintshi. Kwafunyaniswa ukuba isiphumo sobunzima obuhlukeneyo be-mesh yensimbi (i-solder paste) kwi-QFN yafaniswa naleyo ye-mesh yensimbi eprintiweyo kunye nobukhulu be-75 μm Njengoko ubukhulu be-mesh yensimbi bukhula, indawo ye-cavity iyancipha ngokuthe ngcembe. Emva kokufikelela kubukhulu obuthile (i-100μm), indawo ye-cavity iya kuguqulwa kwaye iqale ukunyuka ngokunyuka kobukhulu be-mesh yensimbi, njengoko kuboniswe kuMfanekiso 7.

Oku kubonisa ukuba xa ubuninzi be-solder paste bunyuswa, i-tin engamanzi ene-reflux igutyungelwe yi-chip, kwaye i-outlet ye-residual yokuphunyuka komoya iyancipha kuphela kumacala amane. Xa ubungakanani bento yokuncamathelisa ye-solder butshintshiwe, indawo yokuphuma komoya eyintsalela nayo iye yanda, kwaye ukugqabhuka komoya ngoko nangoko esongelwe kwitoti elulwelo okanye irhasi ebalekayo ephuma kwitoti elulwelo kuya kubangela ukuba inkonkxa yolwelo itshize malunga ne-QFN kunye netshiphu.

Uvavanyo lwafumanisa ukuba ngokunyuka kobunzima bomnatha wentsimbi, ukugqabhuka kweqamza okubangelwa kukuphuncuka komoya okanye irhasi eguquguqukayo nako kuya kwanda, kwaye amathuba okutshiza kwetoti ejikeleze i-QFN kunye ne-chip nawo aya kwanda ngokuhambelanayo.

Ukuthelekiswa kwemingxuma kwi-mesh yensimbi yobunzima obuhlukeneyo

3.3 Umlinganiselo wendawo ye-welding cavity kunye nokuvulwa kwentsimbi yentsimbi

I-mesh yensimbi eprintiweyo enezinga lokuvula i-100%, i-90% kunye ne-80% yavavanywa, kwaye ezinye iimeko zahlala zingatshintshi. Emva kokubuyisela kwakhona, indawo ye-cavity ye-welded layer ilinganiswa kwaye ifaniswa ne-mesh yensimbi eprintiweyo kunye ne-100% yokuvula izinga. Kwafunyaniswa ukuba akukho mmahluko obalulekileyo kwisigxina somgca we-welded phantsi kweemeko zokuvula izinga le-100% kunye ne-90% ye-80%, njengoko kuboniswe kwi-Figure 8.

Ukuthelekiswa kwe-Cavity yendawo eyahlukileyo yokuvula ye-mesh yensimbi eyahlukeneyo

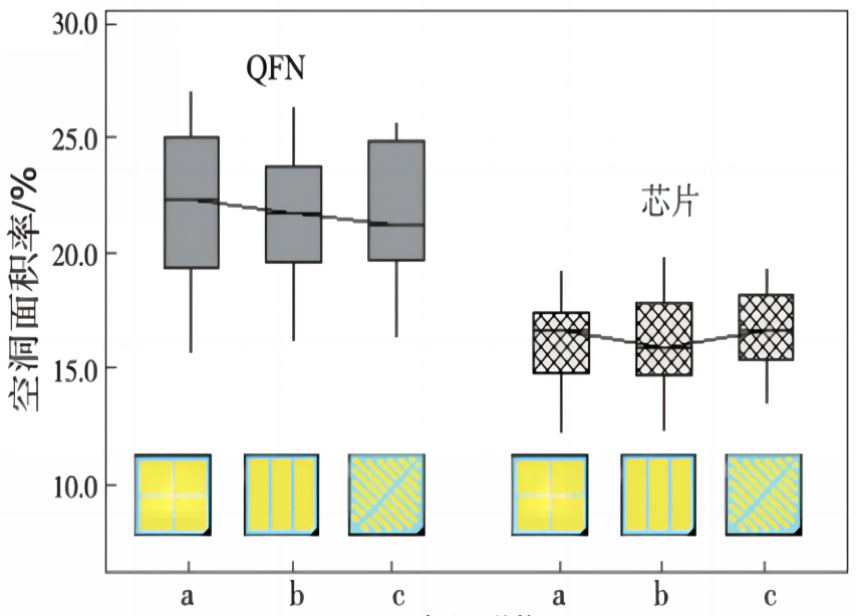

3.4 Umngxuma odityanisiweyo kunye nemilo yentsimbi eprintiweyo

Ngovavanyo lwemilo yoshicilelo lwe-solder paste ye-strip b kunye negridi ethambekeleyo c, ezinye iimeko zihlala zingatshintshi. Emva kokuhamba kwakhona, indawo ye-cavity ye-welding layer ilinganiswa kwaye ithelekiswe kunye nemilo yokushicilela yegridi. Kufunyenwe ukuba akukho mmahluko obalulekileyo kwi-cavity ye-welding layer phantsi kweemeko zegridi, i-strip kunye ne-inclined grid, njengoko kuboniswe kuMfanekiso 9.

Ukuthelekiswa kwemingxuma kwiindlela ezahlukeneyo zokuvula i-mesh yensimbi

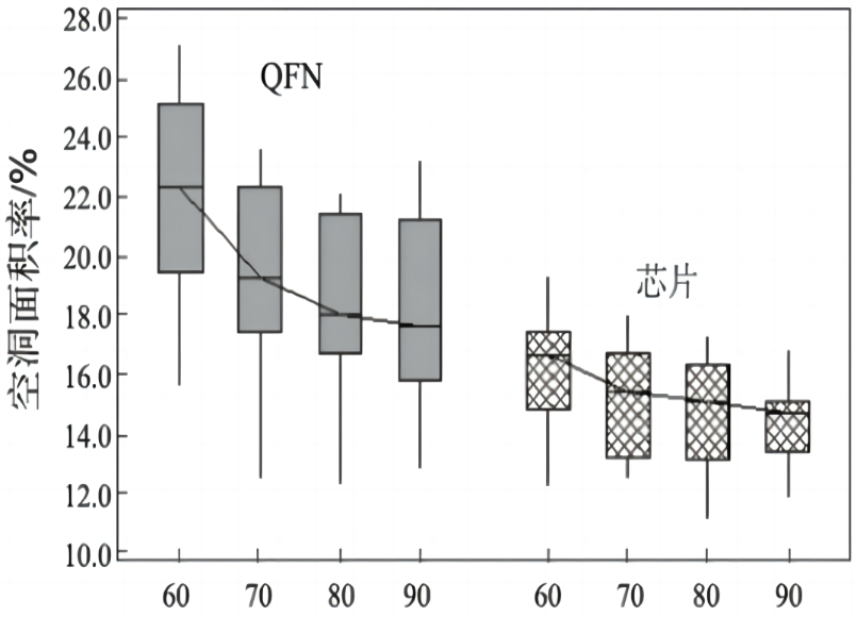

3.5 I-welding cavity kunye nexesha le-reflux

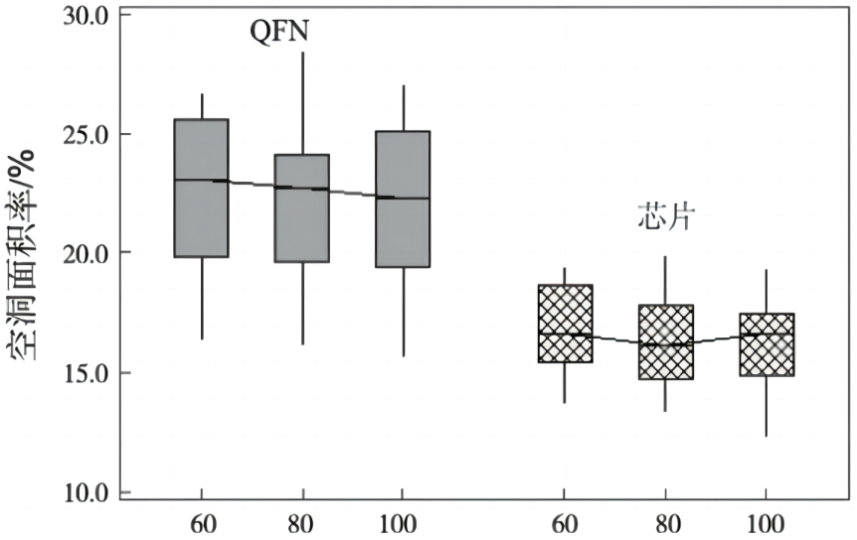

Emva kwexesha elide le-reflux (70 s, 80 s, 90 s) uvavanyo, ezinye iimeko zihlala zingatshintshi, umngxuma kwi-welding layer yalinganiswa emva kwe-reflux, kwaye xa kuthelekiswa nexesha le-reflux ye-60 s, kwafunyaniswa ukuba ngokunyuka kwexesha le-reflux, indawo ye-welding yehla, kodwa ukucutha kwe-welding kuncitshiswe ngokunyuka kwexesha lokunyuka kwe-amplitude. kwimeko yokungonelanga kwexesha le-reflux, ukunyusa ixesha le-reflux kunceda ukuphuphuma ngokupheleleyo komoya ofakwe kwi-tin encibilikisiweyo yolwelo, kodwa emva kwexesha lokunyuka kwe-reflux ukuya kwixesha elithile, umoya ohlanganiswe kwi-tin yolwelo kunzima ukuphuphuma kwakhona. Ixesha le-Reflux yenye yezinto ezichaphazela i-welding cavity.

Ukuthelekisa okungenanto yobude bexesha le-reflux eyahlukileyo

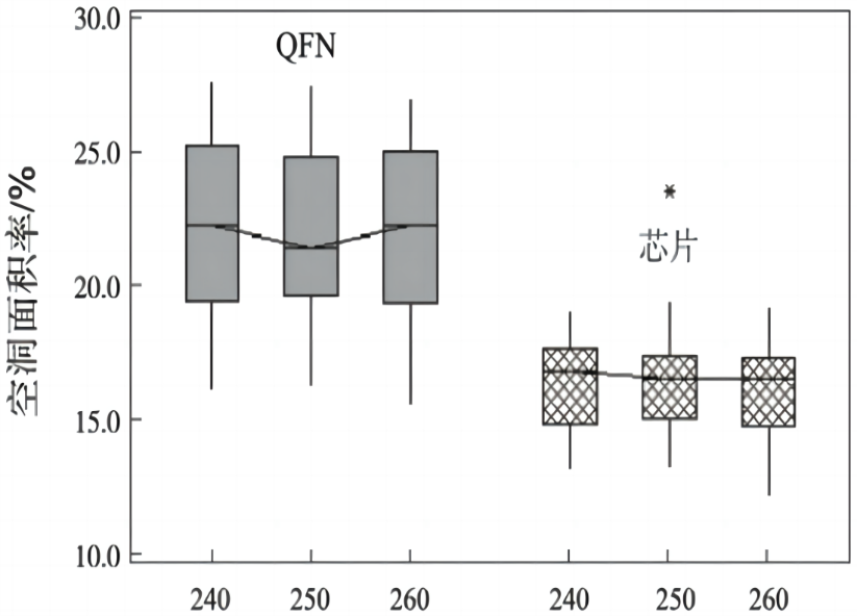

3.6 Umngxunya weWelding kunye nobushushu obuphezulu beziko

Nge-240 ℃ kunye ne-250 ℃ i-peak yokuvavanya ubushushu beziko kunye nezinye iimeko ezingatshintshiyo, indawo ye-cavity ye-welded layer yalinganiswa emva kokuhamba kwakhona, kwaye xa kuthelekiswa ne-260 ℃ i-peak yobushushu beziko lomlilo, kwafunyaniswa ukuba phantsi kweemeko ezahlukeneyo zokushisa eziko, i-cavity ye-welded layer ye-QFN ayizange itshintshe kakhulu. iqondo lobushushu peak eziko ayinayo impembelelo ecacileyo QFN kunye umngxuma umaleko welding ye chip, nto leyo engeyonto enefuthe.

Ukuthelekisa okungenanto kwamaqondo obushushu ahlukeneyo

Olu vavanyo lungentla lubonisa ukuba izinto ezibalulekileyo ezichaphazela i-weld layer ye-QFN kunye ne-chip lixesha le-reflux kunye nobukhulu bentsimbi.

4 Incama ye-Solder yoshicilelo iphinda iphuculwe i-welding cavity

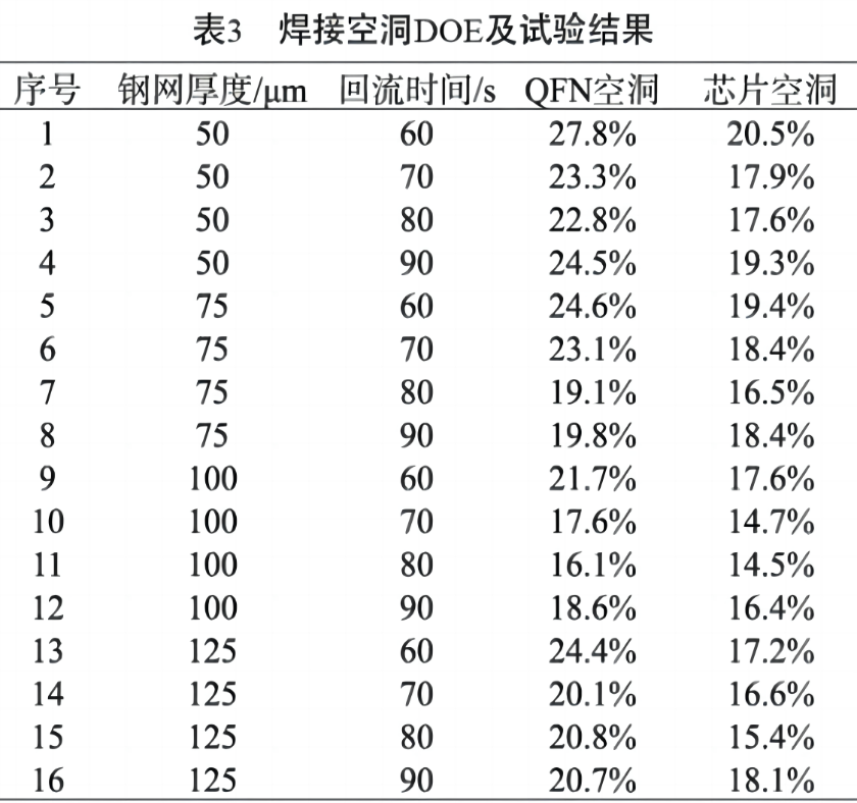

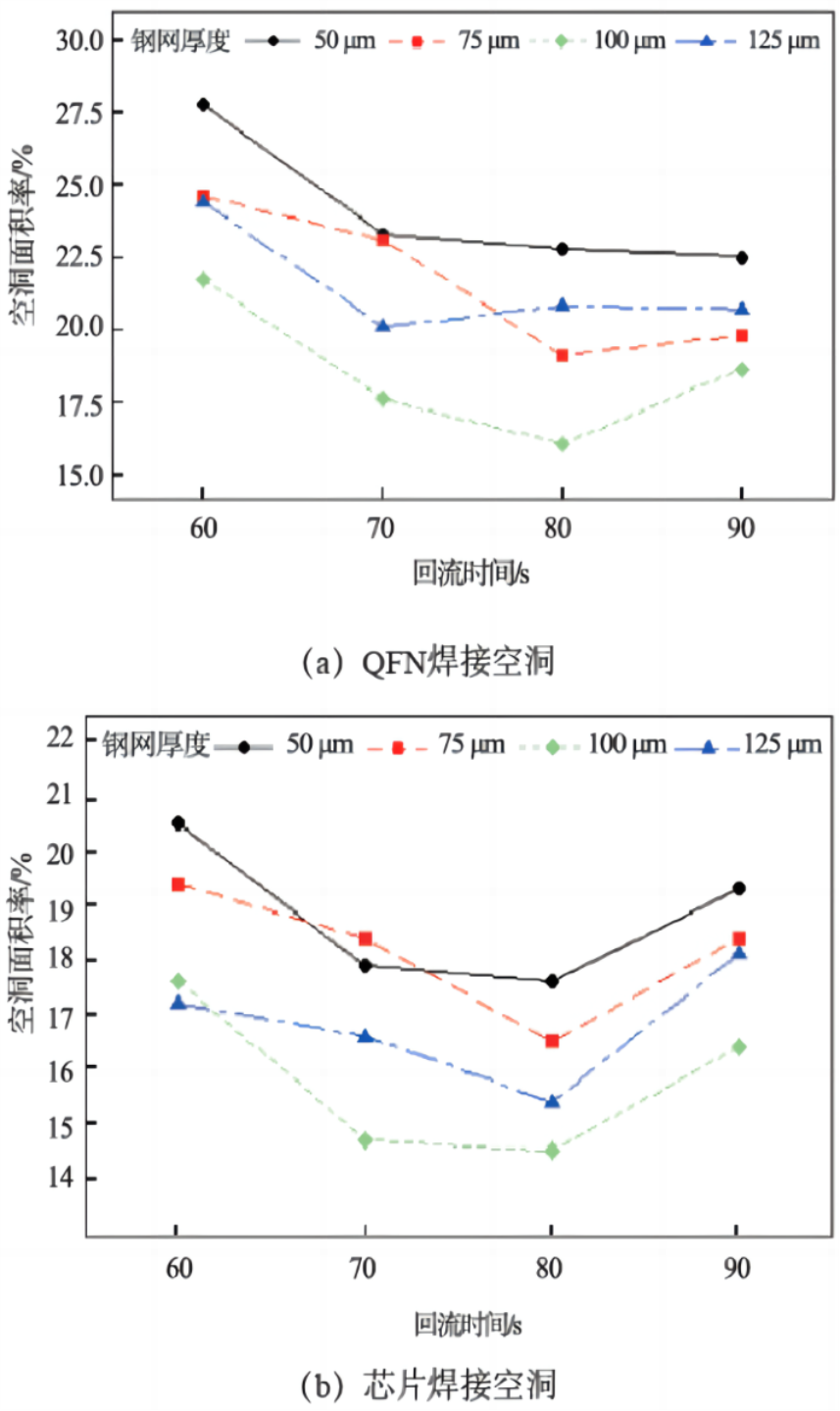

4.1 Uvavanyo lwe-DOE lokuphucula i-welding cavity

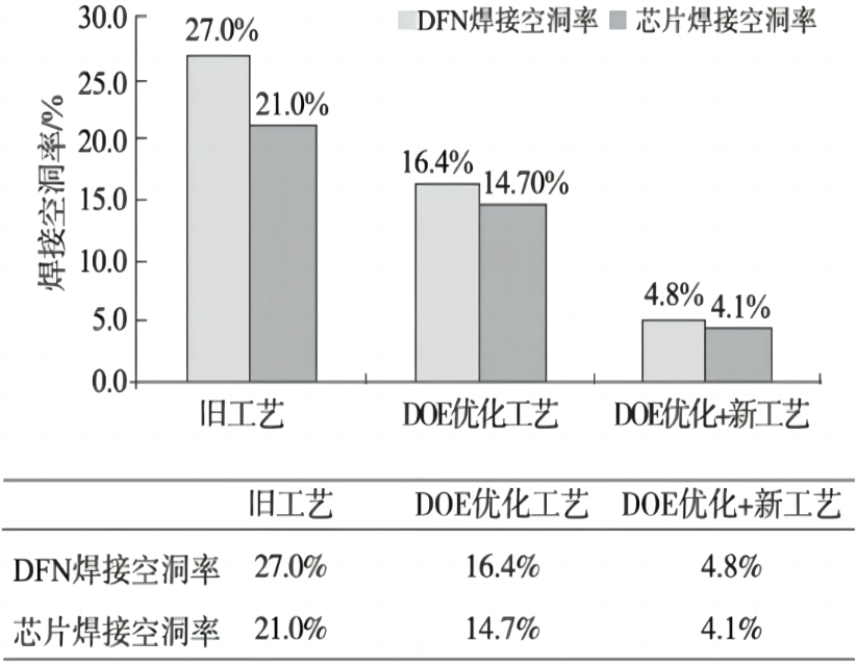

Umngxuma kwi-welding layer ye-QFN kunye ne-chip yaphuculwa ngokufumana ixabiso elifanelekileyo lezona zinto zichaphazelayo (ixesha le-reflux kunye nobukhulu bentsimbi ye-mesh). I-solder paste yayiyi-SAC305 type4, i-mesh yentsimbi yayiyimilo yegridi (i-100% yokuvula idigri), iqondo lokushisa eliphezulu le-furnace laliyi-260 ℃, kunye nezinye iimeko zokuvavanya zifana nezo zezixhobo zokuvavanya. Uvavanyo lwe-DOE kunye neziphumo ziboniswe kwiThebhile 3. Iimpembelelo zentsimbi yentsimbi kunye nexesha le-reflux kwi-QFN kunye nemingxuma ye-chip welding iboniswe kwi-Figure 12. Ngokusebenzisa uhlalutyo lokusebenzisana kwezinto eziphambili ezichaphazelayo, kufunyenwe ukuba ukusebenzisa i-100 μm yentsimbi yentsimbi kunye nexesha le-reflux ye-80 inokunciphisa kakhulu i-welding cavity ye-QN. Izinga le-welding cavity ye-QFN iyancipha ukusuka kwi-27.8% ukuya kwi-16.1% ephezulu, kwaye izinga le-welding cavity ye-chip liyancitshiswa ukusuka kwi-20.5 ephezulu ukuya kwi-14.5%.

Kuvavanyo, iimveliso ze-1000 zaveliswa phantsi kweemeko ezifanelekileyo (i-100 μm ubukhulu bentsimbi ye-mesh, i-80 s ixesha le-reflux), kunye nezinga le-welding cavity ye-100 QFN kunye ne-chip yayilinganiswe ngokungenamkhethe. Umyinge womlinganiselo wokuwelda we-QFN wawuyi-16.4%, kwaye umndilili wesantya sokuwelda kwitshiphu yayiyi-14.7% Umyinge wentsimbi ye-weld yetshiphu kunye netshiphu ngokucacileyo zicuthiwe.

4.2 Inkqubo entsha iphucula i-welding cavity

Imeko yangempela yokuvelisa kunye novavanyo lubonisa ukuba xa indawo ye-welding cavity ephantsi kwe-chip ingaphantsi kwe-10%, ingxaki yokuqhekeka kwendawo ye-chip cavity ayiyi kwenzeka ngexesha lokubambisana kunye nokubumba. Iiparamitha zenkqubo ezilungiselelwe yi-DOE azikwazi ukuhlangabezana neemfuno zokuhlalutya kunye nokusombulula imingxuma kwi-solder paste reflow welding yesiqhelo, kunye nesantya sommandla we-welding we-chip kufuneka sincitshiswe ngakumbi.

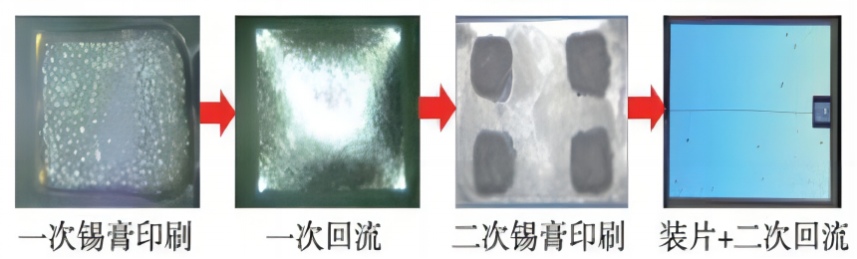

Ekubeni i-chip egqunywe kwi-solder ithintela igesi kwi-solder ekubalekeni, izinga lomngxuma emazantsi e-chip liyancipha ngakumbi ngokuphelisa okanye ukunciphisa igesi efakwe kwi-solder. Inkqubo entsha ye-reflow welding kunye nokuprintwa kwe-solder paste yamkelwa: enye i-solder paste yokushicilela, enye i-reflow ayigubungeli i-QFN kunye ne-chip engenanto ekhupha igesi kwi-solder; Inkqubo ethile yokuprinta i-solder paste yesibini, i-patch kunye ne-reflux yesibini iboniswe kuMfanekiso we-13.

Xa i-75μm intlama ye-solder eshinyeneyo iprintwa okokuqala, uninzi lwerhasi ekwi-solder ngaphandle kwesigqubuthelo setshiphu ibaleka ukusuka kumphezulu, kwaye ubunzima emva kwe-reflux malunga ne-50μm. Emva kokugqitywa kwe-reflux yokuqala, izikwere ezincinci ziprintwa kumphezulu we-solder epholileyo eqinisiweyo (ukwenzela ukunciphisa inani le-solder paste, ukunciphisa umthamo we-gas spillover, ukunciphisa okanye ukuphelisa i-spatter ye-solder), kunye ne-solder paste enobunzima obuyi-50 μm (ezi ziphumo zovavanyo zingasentla zibonisa ukuba ubukhulu be-100 μm yeyona nto ingcono kakhulu ye-50 printing, ngoko ke, i-100 μm yeyona printing ye-10 ye-10 yesibini. μm=50 μm), emva koko faka itshiphu, kwaye emva koko ubuye nge-80 s. Phantse akukho mngxuma kwi-solder emva kokuprintwa kokuqala kunye nokuhamba kwakhona, kwaye i-solder paste kwi-printing yesibini incinci, kwaye umngxuma wokuwelda umncinci, njengoko kubonisiwe kuMfanekiso 14.

Emva kokuprintwa kabini kwe-solder paste, umzobo ongenanto

4.3 Ukuqinisekiswa kwempembelelo ye-welding cavity

Ukuveliswa kweemveliso ze-2000 (ubukhulu be-mesh yokuqala yoshicilelo lwentsimbi yi-75 μm, ubukhulu bentsimbi yesibini yokushicilela i-50 μm), ezinye iimeko azitshintshanga, ukulinganisa okungahleliwe kwe-500 QFN kunye nesantya se-welding ye-chip, yafumanisa ukuba inkqubo entsha emva kwe-reflux yokuqala akukho mgodi, emva kwe-reflux yesibini ye-welding rate ye-QFN kunye ne-4 ye-cavity ye-cavity ephezulu. itshiphu yi-4.1%. Xa kuthelekiswa nenkqubo ye-welding yokuqala yokushicilela i-single-paste kunye nenkqubo ye-DOE ephuculweyo, i-welding cavity iyancipha kakhulu, njengoko kuboniswe kuMzobo 15. Akukho ziqhekeza ze-chip ezifunyenwe emva kovavanyo olusebenzayo lwazo zonke iimveliso.

5 Isishwankathelo

Ukulungiswa kwesixa sokuprinta se-solder kunye nexesha le-reflux kunokunciphisa indawo ye-welding cavity, kodwa izinga le-welding cavity liselikhulu. Ukusebenzisa iindlela ezimbini ze-solder zokuprinta ukuprinta kwe-welding zinokwenza ngokufanelekileyo kunye nokwandisa izinga lokuwelda. Ummandla we-welding ye-QFN yesekethe i-chip engenanto ingaba yi-4.4mm x4.1mm kunye ne-3.0mm x2.3mm ngokulandelanayo kwimveliso yobuninzi Umlinganiselo we-cavity we-welding welding ilawulwa ngaphantsi kwe-5%, ephucula umgangatho kunye nokuthembeka kwe-welding reflow. Uphando kweli phepha lubonelela ngereferensi ebalulekileyo yokuphucula ingxaki ye-welding cavity kwindawo enkulu ye-welding surface.

Ixesha lokuposa: Jul-05-2023