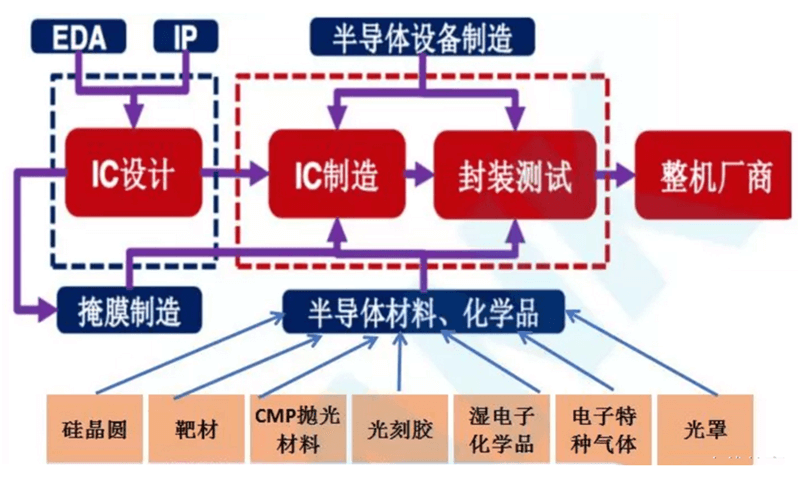

Ukusuka kwimbono yobuchwephesha, inkqubo yokuvelisa itshiphu inzima kakhulu kwaye iyadika. Nangona kunjalo, ukusuka kuluhlu olupheleleyo lwemizi-mveliso ye-IC, yahlulwe kakhulu yangamacandelo amane: uyilo lwe-IC → ukwenziwa kwe-IC → ukupakishwa → uvavanyo.

Inkqubo yokuvelisa iChip:

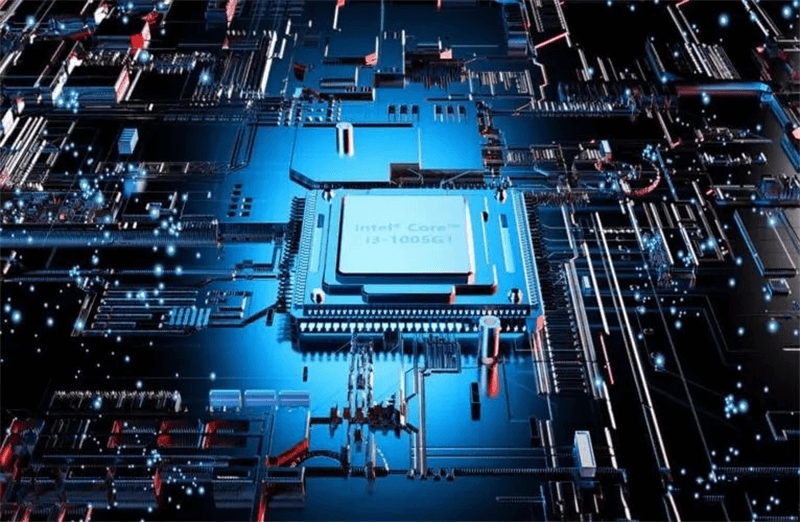

1. Uyilo lweChip

Itshiphu yimveliso enomthamo omncinci kodwa ichaneke kakhulu. Ukwenza i-chip, uyilo yinxalenye yokuqala. Uyilo lufuna uncedo loyilo lwetshiphu yoyilo lwetshiphu olufunekayo ukusetyenzwa ngoncedo lwesixhobo se-EDA kunye nezinye ii-IP cores.

Inkqubo yokuvelisa iChip:

1. Uyilo lweChip

Itshiphu yimveliso enomthamo omncinci kodwa ichaneke kakhulu. Ukwenza i-chip, uyilo yinxalenye yokuqala. Uyilo lufuna uncedo loyilo lwetshiphu yoyilo lwetshiphu olufunekayo ukusetyenzwa ngoncedo lwesixhobo se-EDA kunye nezinye ii-IP cores.

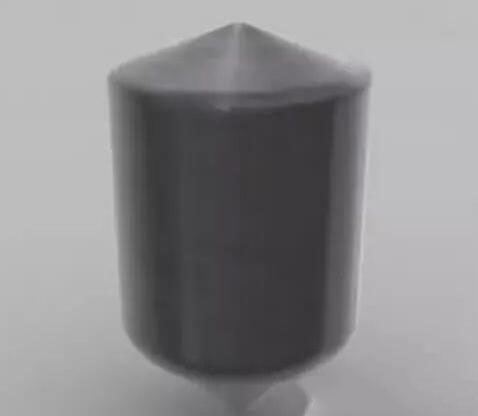

3. I-Silicon -ukuphakamisa

Emva kokuba i-silicon ihlulwe, izinto ezisele zishiywe. I-silicon ecocekileyo emva kwamanyathelo amaninzi ifikelele kumgangatho wokuvelisa i-semiconductor. Le yinto ebizwa ngokuba yi-silicon ye-elektroniki.

4. I-silicon -i-ingots yokuphosa

Emva kokuhlanjululwa, i-silicon kufuneka iphoswe kwii-ingots ze-silicon. Ikristale enye ye-electron-grade silicon emva kokuphonswa kwingot inobunzima obumalunga ne-100 kg, kwaye ukucoceka kwesilicon kufikelela kwi-99.9999%.

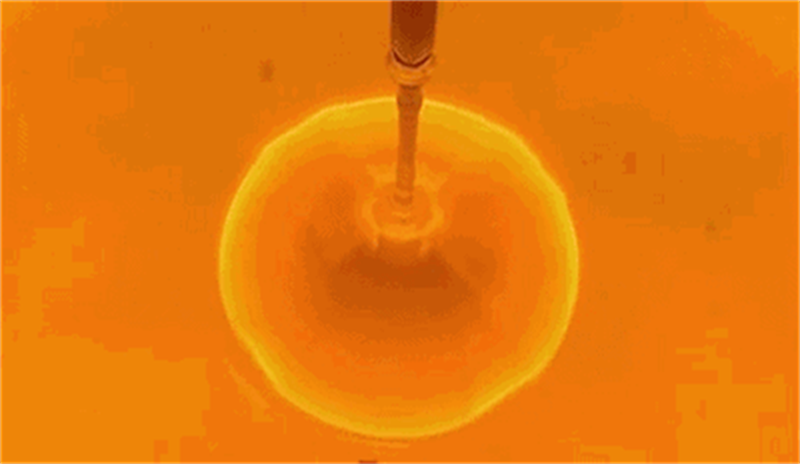

5. Ukulungiswa kweefayile

Emva kokuba i-ingot ye-silicon iphoswe, i-ingot ye-silicon yonke kufuneka inqunyulwe ibe ziziqwenga, nto leyo esiyibiza ngokuba yi-wafer, ebhityile kakhulu. Emva koko, i-wafer igudiswa ide igqibelele, kwaye umphezulu ugudile njengesipili.

Ubukhulu be-silicon wafers yi-8-intshi (200mm) kunye ne-12-intshi (300mm) ububanzi. Ubukhulu bedayamitha, iphantsi ixabiso le-chip enye, kodwa ubunzima bokucubungula.

5. Ukulungiswa kweefayile

Emva kokuba i-ingot ye-silicon iphoswe, i-ingot ye-silicon yonke kufuneka inqunyulwe ibe ziziqwenga, nto leyo esiyibiza ngokuba yi-wafer, ebhityile kakhulu. Emva koko, i-wafer igudiswa ide igqibelele, kwaye umphezulu ugudile njengesipili.

Ubukhulu be-silicon wafers yi-8-intshi (200mm) kunye ne-12-intshi (300mm) ububanzi. Ubukhulu bedayamitha, iphantsi ixabiso le-chip enye, kodwa ubunzima bokucubungula.

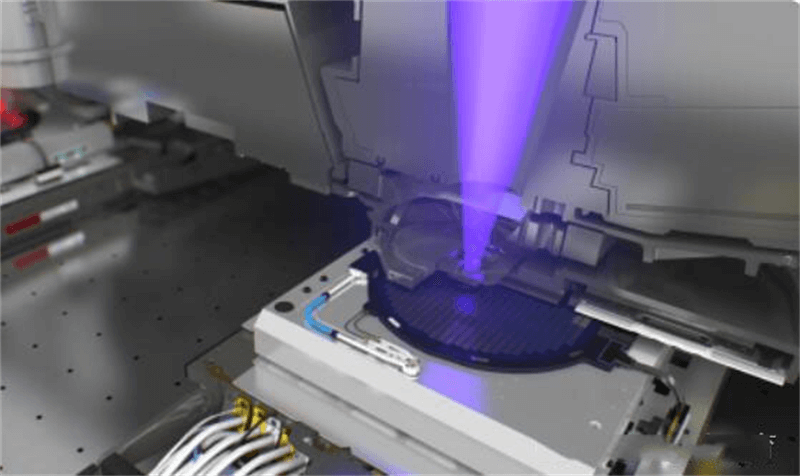

7. Isitofu se-Eclipse kunye ne-ion

Okokuqala, kuyimfuneko ukugqwesa i-silicon oxide kunye ne-silicon nitride evezwe ngaphandle kwe-photoresist, kunye nokunciphisa umaleko we-silicon ukuze ugqume phakathi kwetyhubhu yekristale, emva koko usebenzise itekhnoloji ye-etching ukuveza i-silicon esezantsi. Emva koko ujobe i-boron okanye i-phosphorus kwisakhiwo se-silicon, uze ugcwalise ubhedu ukuze udibanise nezinye ii-transistors, uze usebenzise enye ingqimba yeglue kuyo ukuze wenze uluhlu lwesakhiwo. Ngokubanzi, itshiphu iqulethe intaphane yeeleya, njengohola wendlela ezixineneyo.

7. Isitofu se-Eclipse kunye ne-ion

Okokuqala, kuyimfuneko ukugqwesa i-silicon oxide kunye ne-silicon nitride evezwe ngaphandle kwe-photoresist, kunye nokunciphisa umaleko we-silicon ukuze ugqume phakathi kwetyhubhu yekristale, emva koko usebenzise itekhnoloji ye-etching ukuveza i-silicon esezantsi. Emva koko ujobe i-boron okanye i-phosphorus kwisakhiwo se-silicon, uze ugcwalise ubhedu ukuze udibanise nezinye ii-transistors, uze usebenzise enye ingqimba yeglue kuyo ukuze wenze uluhlu lwesakhiwo. Ngokubanzi, itshiphu iqulethe intaphane yeeleya, njengohola wendlela ezixineneyo.

Ixesha lokuposa: Jul-08-2023