I-PCB ye-multilayer compaction yinkqubo elandelelanayo. Oku kuthetha ukuba isiseko sokubeka iya kuba sisiqwenga sefoyile yobhedu kunye nomaleko we-prepreg obekwe ngaphezulu. Inani leeleya ze-prepreg liyahluka ngokweemfuno zokusebenza. Ukongeza, i-internal core ifakwe kwi-prepreg billet layer kwaye emva koko izaliswe ngumaleko we-billet we-prepreg ogqunywe ngefoyile yobhedu. I-laminate ye-PCB ye-multi-layer yenziwa njalo. Beka i-laminates ezifanayo phezu komnye. Emva kokuba ifoyile yokugqibela yongeziwe, isitakhi sokugqibela senziwe, esibizwa ngokuba “yincwadi,” kwaye isitaki ngasinye sibizwa ngokuba “sisahluko.”

Xa incwadi igqityiwe, idluliselwa kumatshini wokushicilela owenziwe ngehydraulic. Umshicileli we-hydraulic ushushu kwaye usebenzisa inani elikhulu loxinzelelo kunye ne-vacuum kwincwadi. Le nkqubo ibizwa ngokuba kukuphilisa kuba inqanda unxibelelwano phakathi kwe-laminates kunye nomnye kwaye ivumela i-resin prepreg ukuba idibanise nombindi kunye ne-foil. Amacandelo ke ayasuswa kwaye apholiswe kwiqondo lobushushu begumbi ukuvumela i-resin ukuba izinze, ngaloo ndlela igqibezela ukuveliswa kobhedu lwe-PCB yee-multilayer.

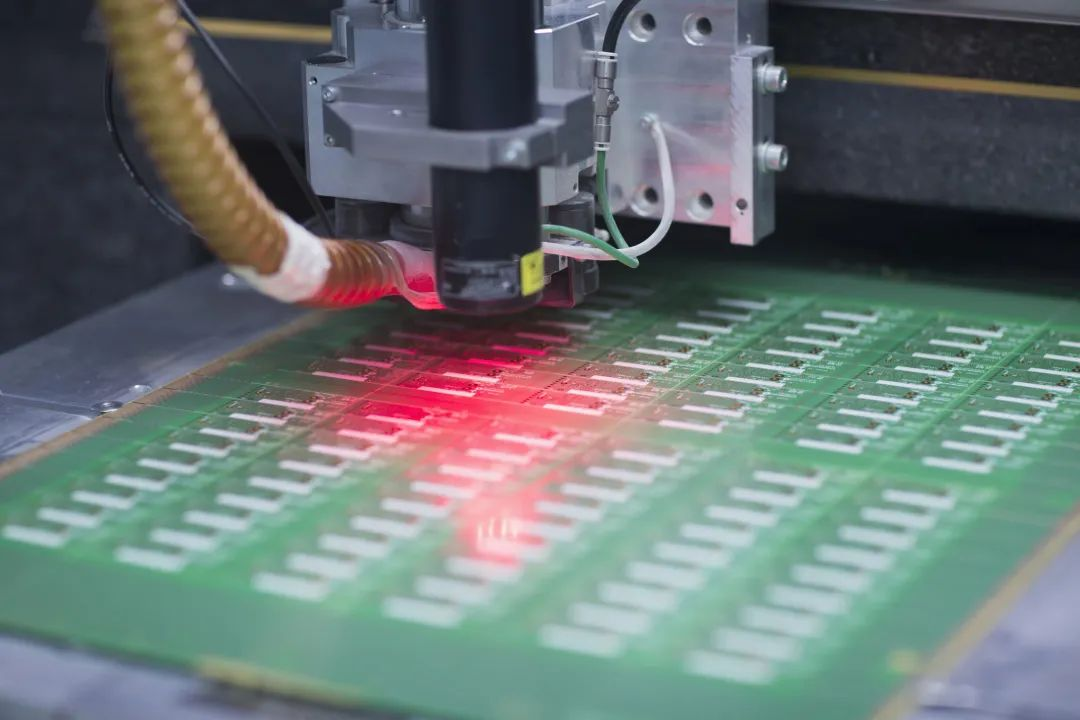

Emva kokuba amaqabunga ahlukeneyo amaqabunga anqunywe ngokuhambelana nobukhulu obuchaziweyo, inani elihlukeneyo lamaphepha likhethwa ngokuhambelana nobukhulu bephepha ukwenza i-slab, kwaye i-slab laminated ihlanganiswe kwiyunithi yokucinezela ngokulandelelana kweemfuno zenkqubo. Tyhiliza iyunithi ecinezelayo kumatshini wokulayita ukuze ucinezele kwaye wenze.

Izigaba ezi-5 zokulawula ubushushu

(a) Inqanaba lokufudumala: iqondo lokushisa lisuka kwiqondo lokushisa ukuya kwiqondo lokuqala lokuphendula okuphilisa umphezulu, ngelixa i-resin ye-core layer ishushu, inxalenye ye-volatiles iyakhutshwa, kwaye uxinzelelo luyi-1/3 ukuya kwi-1/2 yoxinzelelo olupheleleyo.

(b) Inqanaba lokugquma: intlaka yomphezulu iphiliswa ngesantya esisezantsi sokusabela. I-core layer resin ifudunyezwa ngokulinganayo kwaye inyibilike, kwaye i-interface ye-resin layer iqala ukuxubana enye kwenye.

(c) inqanaba lokufudumeza: ukusuka kwiqondo lokushisa lokuqala lokunyanga ukuya kwiqondo lokushisa eliphezulu elichazwe ngexesha lokucinezela, isantya sokufudumeza akufanele sikhawuleze kakhulu, ngaphandle koko isantya sokunyanga somgangatho ophezulu siya kukhawuleza kakhulu, kwaye asinako ukudibanisa kakuhle kunye ne-core layer resin, okubangela ukuchithwa okanye ukuqhekeka kwemveliso egqityiweyo.

D

(e) Inqanaba lokupholisa: Xa i-resin yomgangatho ophakathi we-slab sele iphilisiwe ngokupheleleyo kwaye idityaniswe ngokupheleleyo kunye ne-core layer resin, inokupholiswa kwaye ipholile, kwaye indlela yokupholisa kukudlulisa amanzi okupholisa kwi-plate eshushu yokushicilela, enokuthi ipholiswe ngokwemvelo. Eli nqanaba kufuneka lenziwe phantsi kokugcinwa koxinzelelo oluchaziweyo, kwaye izinga lokupholisa elifanelekileyo kufuneka lilawulwe. Xa ukushisa kweplate kwehla ngaphantsi kweqondo lokushisa elifanelekileyo, ukukhutshwa koxinzelelo kunokwenziwa.

Ixesha lokuposa: Mar-07-2024