Ngexesha lenkqubo yokwenziwa kweebhodi zePCB, iimeko ezininzi ezingalindelekanga ziya kwenzeka, ezinje ngobhedu oluxutywe ne-electroplated, ukufakwa kweekhemikhali zobhedu, ukucakwa kwegolide, ukufakwa kwe-tin-lead alloy plating kunye nolunye ucwecwe lwe-plating delamination. Ngoko yintoni isizathu solu stratification?

Ngaphantsi kwe-irradiation yokukhanya kwe-ultraviolet, i-photoinitiator ethatha amandla okukhanya ichithwa kwiqela elikhululekile elibangela ukusabela kwe-photopolymerization kwaye lenze i-molecule yomzimba engenakunyibilika kwisisombululo se-alkali. Ngaphantsi kwe-exposure, ngenxa ye-polymerization engaphelelanga, ngexesha lenkqubo yophuhliso, ukuvuvukala kwefilimu kunye nokuthambisa, okubangelwa imigca engacacanga kunye nefilimu ewela phantsi, okubangelwa ukuxhamla kakubi phakathi kwefilimu kunye nobhedu; Ukuba ukuvezwa kuninzi, kuya kubangela ubunzima ekuphuhliseni, kwaye kuya kuvelisa i-warping kunye ne-peeling ngexesha lenkqubo yokucoca, ukwenza i-infiltration plating. Ngoko ke kubalulekile ukulawula amandla okuvezwa; Emva kokuba ubuso bobhedu buphathwe, ixesha lokucoca akulula ukuba libe lide kakhulu, kuba amanzi okucoca aqulethe inani elithile lezinto ezi-acidic, nangona umxholo wayo ubuthathaka, kodwa impembelelo ebusweni bobhedu ayikwazi ukuthathwa kancinci, kwaye umsebenzi wokucoca kufuneka uqhutywe ngokuhambelana ngokuthe ngqo kunye nemigaqo yenkqubo.

Esona sizathu sibalulekileyo sokuba umaleko wegolide uwe kumphezulu we-nickel kunyango lomphezulu we-nickel. Umsebenzi ongekho mgangathweni wesinyithi we-nickel kunzima ukufumana iziphumo ezanelisayo. Umphezulu we-nickel yokugquma kulula ukuvelisa ifilimu ye-passivation emoyeni, njengonyango olungafanelekanga, luya kwahlula i-gold layer ukusuka kumphezulu we-nickel layer. Ukuba usetyenziso alufanelekanga kwi-electroplating, uluhlu lwegolide luya kususwa kumphezulu we-nickel layer kunye ne-peel off. Isizathu sesibini kukuba emva kokusebenza, ixesha lokucoca lide kakhulu, nto leyo ebangela ukuba ifilimu ye-passivation yenziwe kwakhona kumphezulu we-nickel, kwaye emva koko ifakwe kwi-gilded, eya kuthi ngokuqinisekileyo ivelise iziphene kwi-coating.

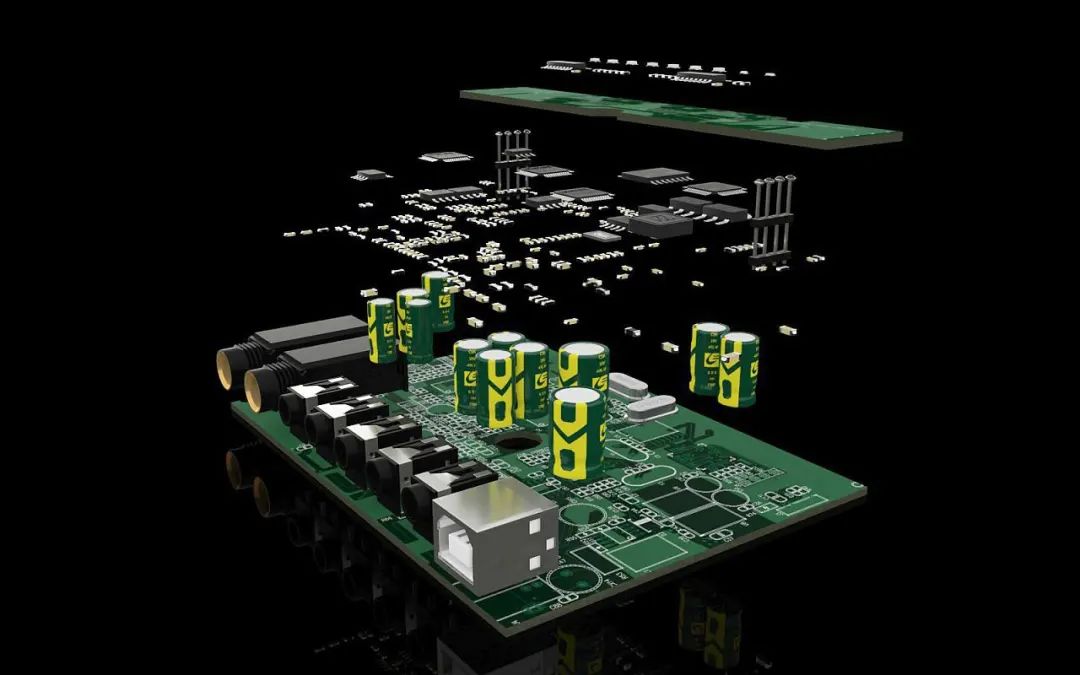

Zininzi izizathu zokubeka i-delamination, ukuba ufuna ukwenza imeko efanayo kwinkqubo yokuvelisa ipleyiti ingenzeki, inonxibelelwano olubalulekileyo kunye nokhathalelo kunye noxanduva lweengcali. Ke ngoko, umenzi wePCB ogqwesileyo uya kuqhuba uqeqesho olukumgangatho ophezulu kumqeshwa ngamnye weworkshop ukuze kuthintelwe ukuhanjiswa kweemveliso ezikumgangatho ophantsi.

Ixesha lokuposa: Apr-07-2024