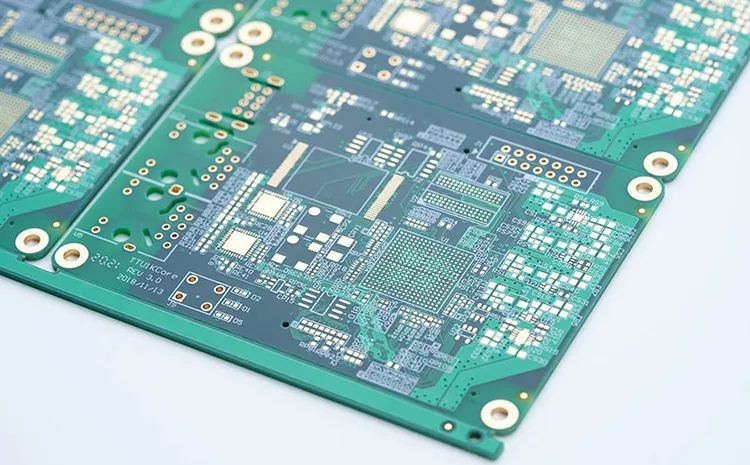

I-PCB ngenxa yokuchaneka kwayo nokuba ngqongqo kwayo, iimfuno zempilo yokusingqongileyo kuzo zonke iindibano zocweyo zePCB ziphezulu kakhulu, kwaye ezinye iindibano zocweyo zide zibe sesichengeni “sokukhanya okutyheli” imini yonke. Ukufuma, kwakhona sesinye sezibonakaliso ezifuna ukulawulwa ngokungqongqo, namhlanje siza kuthetha ngempembelelo yokufuma kwi-PCBA.

"Ukufuma" okubalulekileyo

Ukufuma sisalathisi esibaluleke kakhulu kwaye silawulwa ngokungqongqo kwinkqubo yokuvelisa. Ukufuma okuphantsi kunokubangela ukoma, ukwanda kwe-ESD, ukwanda kwamanqanaba othuli, ukuvaleka ngokulula kokuvuleka kwetemplate, kunye nokunyuka kokunxiba kwetemplate. Uqheliselo lubonakalise ukuba ukufuma okuphantsi kuya kuchaphazela ngokuthe ngqo kwaye kunciphise umthamo wemveliso. Ukuphakama kakhulu kuya kubangela ukuba izinto zifunxe ukufuma, okukhokelela kwi-delamination, iziphumo ze-popcorn, kunye neebhola ze-solder. Ukufuma kwakhona kunciphisa ixabiso le-TG lezinto eziphathekayo kwaye kwandisa i-warping eguquguqukayo ngexesha le-welding ye-reflow.

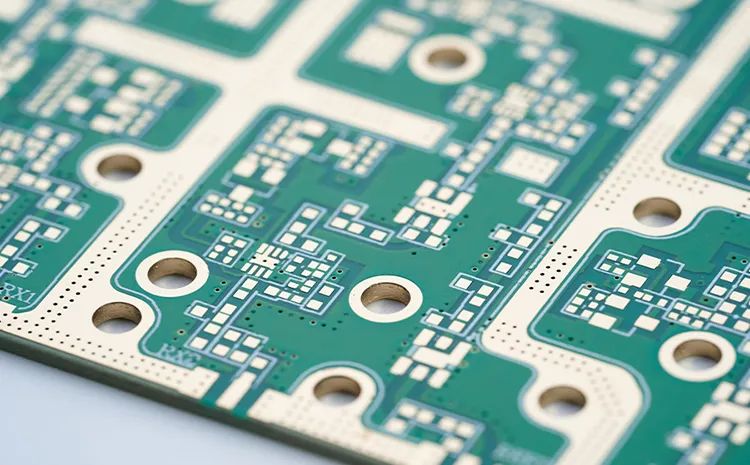

Intshayelelo yokufuma komhlaba

Phantse yonke imiphezulu eqinileyo (enjengentsimbi, iglasi, iiseramikhi, isilicon, njl. njl.) inomaleko omanzi ofunxa amanzi (omnye okanye oneemolekyuli ezininzi) obonakala xa ubushushu bomphezulu bulingana neqondo lombethe lobushushu bomoya ojikelezileyo (kuxhomekeke kubushushu, ukufuma, kunye noxinzelelo lomoya). Ukruthakruthwano phakathi kwesinyithi kunye nentsimbi luyenyuka ngokuncipha kokufuma, kwaye xa kufumama okunxulumene ne-20% RH nangaphantsi, ukukhuhlana kukuphinda-phindwe ka-1.5 ngaphezulu kokufuma okunxulumene nama-80% e-RH.

I-Porous okanye ukufuma okufunxa iindawo (i-epoxy resins, iiplastiki, ii-fluxes, njl.) zivame ukufunxa ezi maleko ezifunxayo, kwaye naxa ubushushu bomphezulu bungaphantsi kwendawo yombethe (i-condensation), umaleko wokufunxa oqulethe amanzi awubonakali kumphezulu wezinto eziphathekayo.

Ngamanzi akwimaleko afunxa imolekyuli enye kule miphezulu angena kwisixhobo seplastiki sokugquma iplastiki (MSD), kwaye xa umaleko wemolekyuli enye efunxayo isondela kumaleko angama-20 ubukhulu, ukufuma okufunxwa yile maleko yokufunxa imolekyuli enye ekugqibeleni kubangela isiphumo sepopcorn ngexesha lokuphinda kufakwe i-soldering.

Impembelelo yokufuma ngexesha lokuvelisa

Ukufuma kuneempembelelo ezininzi kwimveliso nakwimveliso. Ngokuqhelekileyo, umswakama awubonakali (ngaphandle kobunzima obuninzi), kodwa iziphumo ziyi-pores, i-voids, i-solder spatter, iibhola ze-solder, kunye ne-bottom-fill voids.

Kuyo nayiphi na inkqubo, ukulawulwa komswakama kunye nomswakama kubaluleke kakhulu, ukuba ukubonakala kwendawo yomzimba akuqhelekanga, imveliso egqityiweyo ayifanelekanga. Ngoko ke, iworkshop eqhelekileyo kufuneka iqinisekise ukuba umswakama kunye nomswakama we-substrate surface kulawulwa ngokufanelekileyo ukuqinisekisa ukuba izikhombisi zokusingqongileyo kwinkqubo yokuvelisa imveliso egqityiweyo ziphakathi koluhlu oluchaziweyo.

Ixesha lokuposa: Mar-26-2024