I-SMT i-adhesive, eyaziwa ngokuba yi-SMT adhesive, i-SMT ebomvu edibeneyo, idla ngokuba yi-red (nayo ephuzi okanye emhlophe) i-paste esasazwa ngokulinganayo kunye ne-hardener, i-pigment, i-solvent kunye nezinye izinto ezinamathele, ezisetyenziselwa ukulungisa amacandelo ebhodini lokushicilela, ngokubanzi ihanjiswa ngokusasazwa okanye iindlela zokuprinta isikrini sentsimbi. Emva kokugxumeka amacandelo, zibeke kwi-oven okanye i-reflow furnace yokufudumala kunye nokuqina. Umahluko phakathi kwayo kunye ne-solder paste kukuba iphiliswa emva kokushisa, iqondo lokukhenkceza liyi-150 ° C, kwaye ayiyi kuchithwa emva kokuhlaziya, oko kukuthi, inkqubo yokuqina kobushushu bepatch ayinakuguqulwa. Ukusetyenziswa kwe-adhesive ye-SMT kuya kuhluka ngenxa yeemeko zokunyanga kwe-thermal, into edibeneyo, izixhobo ezisetyenzisiweyo, kunye nendawo yokusebenza. I-adhesive kufuneka ikhethwe ngokwenkqubo yebhodi yesekethe eprintiweyo (PCBA, PCA).

Iimpawu, ukusetyenziswa kunye nethemba le-SMT patch adhesive

Iglu ebomvu ye-SMT luhlobo lwe-polymer compound, amacandelo aphambili zizinto ezisisiseko (oko kukuthi, eyona nto iphezulu ye-molecular material), i-filler, i-ejenti yokunyanga, ezinye izongezo kunye nokunye. Iglu ebomvu ye-SMT ine-viscosity fluidity, iimpawu zobushushu, iimpawu zokumanzisa njalo njalo. Ngokwale mpawu yeglue ebomvu, kwimveliso, injongo yokusebenzisa iglue ebomvu kukukwenza iindawo zibambelele ngokuqinileyo kumphezulu wePCB ukuthintela ukuwa. Ke ngoko, i-adhesive patch kusetyenziso olusulungekileyo lweemveliso zenkqubo ezingabalulekanga, kwaye ngoku kunye nokuphuculwa okuqhubekayo koyilo lwePCA kunye nenkqubo, ngokuphinda umngxuma kunye ne-double-side-side reflow welding iye yaphunyezwa, kwaye inkqubo yokunyuswa kwe-PCA usebenzisa i-adhesive patch ibonisa umkhwa wokuncinci nangaphantsi.

Injongo yokusebenzisa i-SMT adhesive

① Thintela izixhobo ekubeni zingawi kwi-soldering ye-wave soldering. Xa usebenzisa i-soldering wave, amacandelo agxininiswe kwibhodi eprintiweyo ukukhusela amacandelo ukuba angawi xa ibhodi eprintiweyo idlula kwi-solder groove.

② Ukuthintela elinye icala lamacandelo ekuweni kwi-welding ye-reflow (inkqubo ye-welding ephindwe kabini). Kwinkqubo ye-welding ye-double-side-side reflow welding, ukwenzela ukukhusela izixhobo ezinkulu kwicala elithengisiweyo ukuba zingawi ngenxa yokuncibilika kobushushu be-solder, i-SMT patch glue kufuneka yenziwe.

③ Thintela ukufuduswa kunye nokuma kwamalungu (inkqubo ye-welding reflow, inkqubo yokwaleka kwangaphambili). Isetyenziswe kwiinkqubo ze-welding reflow kunye neenkqubo zokugubungela kwangaphambili ukukhusela ukufuduka kunye nokunyuka ngexesha lokunyuka.

④ Phawula (i-wave soldering, i-reflow welding, i-pre-coating). Ukongezelela, xa iibhodi eziprintiweyo kunye namacandelo aguqulwa kwiibhetshi, i-adhesive patch isetyenziselwa ukumakisha.

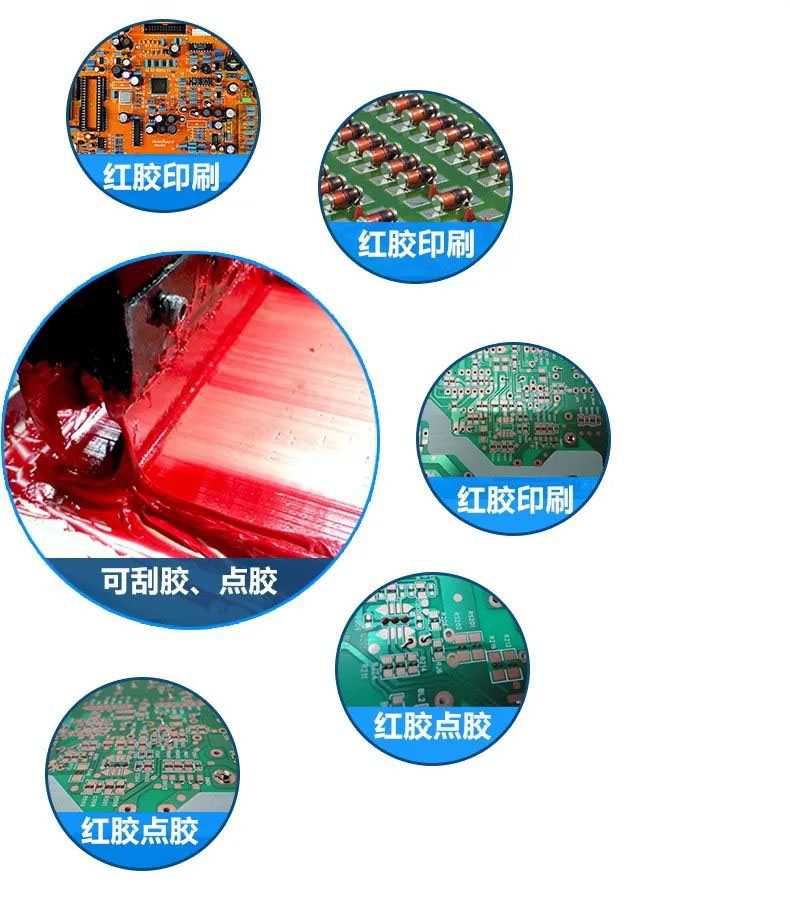

I-adhesive ye-SMT ihlelwa ngokwendlela yokusetyenziswa

a) Uhlobo lokukrala: ukulinganisa kuqhutyelwa ngokuprinta kunye nemodi yokukrazula ye-mesh yensimbi. Le ndlela yeyona isetyenziswa kakhulu kwaye inokusetyenziswa ngokuthe ngqo kwi-solder paste press. Imingxuma yentsimbi yentsimbi kufuneka imiselwe ngokohlobo lwamacandelo, ukusebenza kwe-substrate, ubukhulu kunye nobukhulu kunye nokuma kwemingxuma. Iinzuzo zayo zisantya esiphezulu, ukusebenza kakuhle kunye neendleko eziphantsi.

b) Uhlobo lokukhupha: Iglu isetyenziswe kwibhodi yesekethe eprintiweyo ngokukhupha izixhobo. Kufuneka izixhobo ezikhethekileyo zokuhambisa, kwaye ixabiso liphezulu. Izixhobo zokukhupha kukusetyenziswa komoya ocinezelweyo, iglu ebomvu ngentloko ekhethekileyo yokuhambisa kwi-substrate, ubungakanani bendawo yeglue, kangakanani, ngexesha, ubukhulu betyhubhu yoxinzelelo kunye nezinye iiparitha zokulawula, umatshini wokukhupha unomsebenzi oguquguqukayo. Kwiindawo ezahlukeneyo, sinokusebenzisa iintloko ezihlukeneyo zokukhupha, ukubeka iiparitha zokutshintsha, unokutshintsha kwakhona imilo kunye nobuninzi benqaku leglue, ukuze ufezekise umphumo, iinzuzo zilungele, ziguquguquke kwaye zizinzile. Ukungalungi kulula ukuba nomzobo wocingo kunye namaqamza. Sinokuhlengahlengisa iiparamitha zokusebenza, isantya, ixesha, uxinzelelo lomoya, kunye nobushushu ukuze sinciphise ezi ntsilelo.

I-SMT Patching Eqhelekileyo CICC

lumnka:

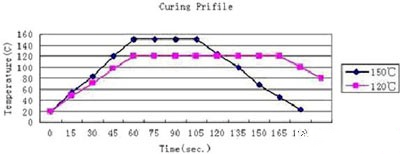

1. Ukuphakama kweqondo lokushisa lokunyanga kunye nexesha elide lokunyanga, amandla okunamathela anamandla.

2. Ngenxa yokuba ukushisa kwe-patch glue kuya kutshintsha kunye nobukhulu beengxenye ze-substrate kunye nesikhundla se-sticker, sincoma ukufumana iimeko ezifanelekileyo zokuqina.

SMT patch glue yokugcina

Inokugcinwa iintsuku ezi-7 kwiqondo lokushisa, ukugcinwa kukhulu kunoJuni ngaphantsi kwe-5 ° C, kwaye inokugcinwa ngaphezu kweentsuku ezingama-30 kwi-5-25 ° C.

I-SMT patch gum ulawulo

Ngenxa yokuba iglu ebomvu ye-SMT ichatshazelwa liqondo lobushushu, iimpawu ze-viscosity, ubumanzi, kunye nobumanzi be-SMT, iglu ebomvu ye-SMT kufuneka ibe neemeko ezithile kunye nolawulo olusemgangathweni.

1) Iglu ebomvu kufuneka ibe nenombolo ethile yokuhamba, kunye namanani ngokwenani lokutya, umhla, kunye neentlobo.

2) Iglue ebomvu kufuneka igcinwe kwifriji ye-2 ukuya ku-8 ° C ukukhusela iimpawu zeempawu ngenxa yokutshintsha kweqondo lokushisa.

I-3) Ukubuyiswa kweglue ebomvu kufuna iiyure ezi-4 kwindawo yokushisa, kwaye isetyenziswe ngomyalelo we-advanced first.

4) Ngemisebenzi yokuzaliswa kwamanqaku, i-glue tube glue ebomvu kufuneka yenziwe. Kwiglue ebomvu engazange isetyenziswe ngexesha elinye, kufuneka ibuyiselwe efrijini ukuze igcinwe.

5) Gcwalisa ifom yokurekhoda ngokuchanekileyo. Ixesha lokubuyisela kunye nokufudumala kufuneka lisetyenziswe. Umsebenzisi kufuneka aqinisekise ukuba ukubuyiswa kugqityiwe ngaphambi kokuba kusetyenziswe. Ngokuqhelekileyo, iglue ebomvu ayinakusetyenziswa.

Iimpawu zenkqubo ye-SMT patch glue

Ubunzulu boQhagamshelwano: I-SMT patch glue kufuneka ibe namandla oqhagamshelwano oluqinileyo. Emva kokuqina, ubushushu be-weld melt abuhluthwanga.

Indawo yokwaleka: Okwangoku, indlela yokuhanjiswa kwebhodi yoshicilelo isetyenziswa kakhulu, ngoko ke kuyafuneka ukuba kubekho oku kulandelayo:

① Ziqhelanise nezincamathelisi ezahlukeneyo

② Kulula ukuseta unikezelo lwecandelo ngalinye

③ Ziqhelanise ngokulula neentlobo zecandelo lokutshintsha

④ Indawo yokwaleka izinzile

Ukuqhelanisa noomatshini abanesantya esiphezulu: Iglu ngoku kufuneka idibane nesantya esiphezulu sokutyabeka kunye nomatshini okwisantya esiphezulu. Ngokukodwa, i-dot-speed dot ithathwa ngaphandle kokudweba, kwaye xa i-high-speed paste ifakwe, ibhodi eprintiweyo ikwinkqubo yokuhanjiswa. Ukunamathela kwetape gum kufuneka kuqinisekise ukuba icandelo alishukumi.

Ukukhwela kunye nokuwa: Emva kokuba i-patch glue ihlanjululwe kwi-pad, icandelo alikwazi ukuxhunywa kwikhonkco lombane kunye nebhodi eprintiweyo. Ukuphepha iipads zongcoliseko.

Ukunyanga ubushushu obuphantsi: Xa uqina, sebenzisa kuqala i-peak-welded insufficient in heat-resistant inserted components to welded, ngoko ke kufuneka ukuba iimeko zokuqina kufuneka zihlangabezane nobushushu obuphantsi kunye nexesha elifutshane.

Ukulungelelaniswa kwe-self-adjustability: Kwi-re-welding and pre-coating process, i-patch glue iqinisiwe kwaye igxininise amacandelo ngaphambi kokuba i-weld inyibilike, ngoko iya kuthintela ukucwiliswa kwe-meta kunye nokuzilungisa. Kule ngongoma, abavelisi baye baphuhlisa i-self-adjustable patch glue.

SMT patch glue iingxaki eziqhelekileyo, iziphene kunye nohlalutyo

Ukutyhala okungonelanga

Iimfuno zamandla e-thrust ye-0603 capacitor yi-1.0kg, ukuxhathisa yi-1.5kg, amandla e-thrust ye-0805 capacitor yi-1.5kg, kwaye ukuxhathisa yi-2.0kg.

Ibangwa ngokubanzi zezi zizathu zilandelayo:

1. Iglue eyaneleyo.

2. Akukho 100% yokuqinisa i-colloid.

3. Iibhodi PCB okanye amacandelo zingcolisekile.

4. I-colloid ngokwayo i-crispy kwaye ayinayo amandla.

I-Tentile ayizinzanga

Iglue yesirinji eyi-30ml idinga ukubethelwa luxinzelelo amashumi amawaka amaxesha ukuze igqitywe, ngoko ke kuyafuneka ukuba ibenobuchule obugqwesileyo ngokugqithisileyo ngokwayo, kungenjalo iya kubangela ukungazinzi kweglu kunye neglu engaphantsi. Xa i-welding, icandelo liyawa. Ngokuchasene noko, i-glue egqithisileyo, ngakumbi kumacandelo amancinci, kulula ukunamathela kwi-pad, ukuthintela uxhumano lombane.

Indawo engonelanga okanye evuzayo

Izizathu kunye namanyathelo okuthintela:

1. Ibhodi enetha yokuprinta ayihlanjwa rhoqo, kwaye i-ethanol kufuneka ihlanjwe rhoqo kwiiyure ezisi-8.

2. I-colloid inokungcola.

3. Ukuvulwa kwe-mesh akunangqiqo okanye kuncinci okanye uxinzelelo lwegesi yeglue luncinci.

4. Kukho amaqamza kwicolloid.

5. Gxuma intloko ukuvala, kwaye ngokukhawuleza ucoce umlomo werabha.

6. Ukushisa kwangaphambi kokushisa kwendawo ye-tape ayanelanga, kwaye ubushushu bompompo kufuneka bubekwe kwi-38 ° C.

Ibrashi

Okubizwa ngokuba yi-brushed kukuba i-patch ayiphulwanga xa i-dicture, kwaye i-patch ixhunyiwe kwi-dot-headed direction direction. Kukho iingcingo ezininzi, kwaye i-patch glue ihlanganiswe kwi-pad eprintiweyo, eya kubangela i-welding embi. Ngokukodwa xa ubukhulu bukhulu, le nto inokwenzeka ukuba yenzeke xa usebenzisa umlomo wakho. Ukuhlaliswa kweebhrashi zeglue yesilayi kuchaphazeleka ikakhulu sisithako saso seebrashi zentlaka kunye noseto lweemeko zokugquma indawo:

1. Yandisa i-tide stroke ukunciphisa isantya sentshukumo, kodwa iya kunciphisa ifandesi yakho yemveliso.

2. I-viscosity encinci, i-high-touch material, encinci ukuthambekela komzobo, ngoko zama ukukhetha olu hlobo lwetape.

3. Ukwandisa kancinci ukushisa kwe-thermal regulator, kwaye uyilungise kwi-viscosity ephantsi, i-high-touch kunye ne-degeneration patch glue. Ngeli xesha, ixesha lokugcina i-patch glue kunye noxinzelelo lwentloko yempompo kufuneka kuthathelwe ingqalelo.

Ukuwa

Ubumanzi beglu yeglu bubangela ukuwa. Ingxaki eqhelekileyo yokuwa kukuba iya kubangela ukuwa emva kokubekwa ixesha elide. Ukuba i-glue ye-patch yandiswa kwi-pad kwibhodi yesekethe eprintiweyo, iya kubangela i-welding embi. Kwaye kulawo macandelo anezikhonkwane eziphezulu, azikwazi ukuqhagamshelana nomzimba oyintloko wecandelo, eliya kubangela ukunamathiswa okwaneleyo. Ngoko ke, kulula ukuwa. Kuxelwe kwangaphambili, ngoko ke ukusetwa kokuqala kwendawo yokwaleka kwayo kukwanzima. Ukusabela koku, kwafuneka sikhethe ezo kwakungelula ukuba ziwe. Ukuwa okubangelwa ngamachaphaza ixesha elide, sinokusebenzisa i-patch glue kunye nokuqina ngexesha elifutshane lokuphepha.

Iseti yecandelo

I-Component offset yinto embi ethanda ukuba noomatshini bepatch abanesantya esiphezulu. Esona sizathu singundoqo:

1. Yi-offset eyenziwe yi-XY direction xa ibhodi eprintiweyo ihamba ngesantya esiphezulu. Esi siganeko sithambekele ekubeni senzeke kwicandelo elinendawo encinci yokugquma iglu. Isizathu sibangelwa ukunamathela.

2. Ayihambelani nesixa seglue phantsi kwecandelo (umzekelo: amanqaku ama-2 eglue ngaphantsi kwe-IC, inqaku leglue likhulu kunye nenqaku elincinci leglue). Xa i-glue ishushu kwaye iqinisiwe, amandla awalingani, kwaye enye isiphelo kunye nenani elincinci leglue kulula ukucima.

Ukuwelda inxalenye yencopho

Unobangela unzima kakhulu:

1. Ukunganyaniseki okwaneleyo kwi-patch glue.

2. Phambi kokudityaniswa kwamaza, yabethwa phambi kokuba i-welding.

3. Kukho iintsalela ezininzi kumacandelo athile.

4. Impembelelo ephezulu yokushisa kwe-colloidity ayichasananga nokushisa okuphezulu

I-Patch glue ixutywe

Abavelisi abahlukeneyo bahluke kakhulu ekubunjweni kweekhemikhali. Ukusetyenziswa okuxubileyo kubangelwa ukuba kubangele ezininzi ezimbi: 1. Ubunzima obusisigxina; 2. Ukuncamathela okunganeleyo; 3. Amalungu adityanisiweyo kakhulu phezu kwencopho.

Isisombululo kukuba: ukucoca ngokucokisekileyo i-mesh, i-scraper, kunye nentloko yentloko, ekulula ukubangela ukusetyenziswa okuxubileyo ukuphepha ukuxuba ukusetyenziswa kweempawu ezahlukeneyo ze-patch glue.

Ixesha lokuposa: Jun-19-2023