Ubeko olufanelekileyo lwamacandelo e-elektroniki kwibhodi yePCB likhonkco elibaluleke kakhulu lokunciphisa iziphene ze-welding! Amacandelo kufuneka aphephe iindawo ezinexabiso elikhulu kakhulu lokuphambuka kunye nemimandla ephezulu yoxinzelelo lwangaphakathi kangangoko kunokwenzeka, kwaye uyilo kufuneka lulingane kangangoko.

Ukuze kwandiswe ukusetyenziswa kwesithuba ibhodi yesekethe, ndiyakholelwa ukuba amaqabane amaninzi uyilo uya kuzama ukubeka amacandelo ngokuchasene emphethweni webhodi, kodwa eneneni, lo mkhuba uya kuzisa ubunzima obukhulu kwimveliso kunye PCBA indibano, kwaye nokuba kukhokelela ekungakwazini ukuwelda indibano oh!

Namhlanje, makhe sithethe ngokucwangciswa kwesixhobo somphetho ngokweenkcukacha

Ingozi yoyilo lwesixhobo secala lephaneli

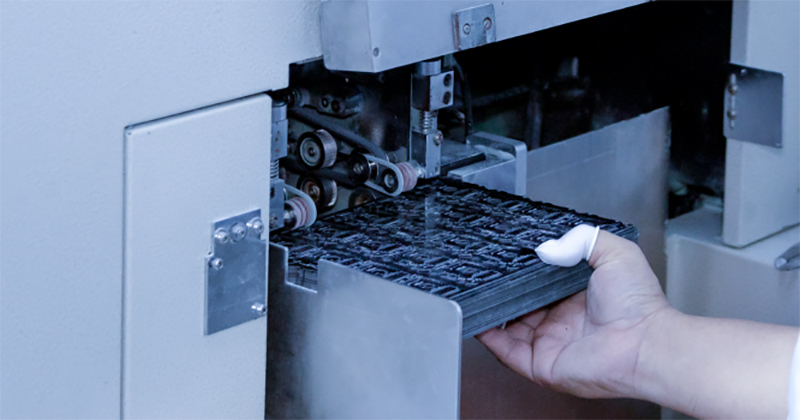

01. Ibhodi yokubumba edge yokusila ibhodi

Xa amacandelo abekwe kufutshane kakhulu kumda weplate, i-welding pad yamacandelo iya kuchithwa xa i-plate yokugaya yenziwe. Ngokuqhelekileyo, umgama phakathi kwe-welding pad kunye nomda kufuneka ube mkhulu kune-0.2mm, ngaphandle koko i-welding pad ye-edge device iya kuchithwa kwaye indibano yangasemva ayikwazi ukuthunga amacandelo.

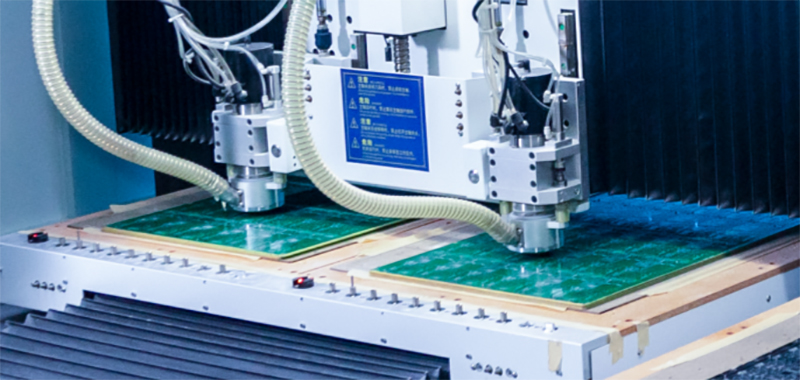

02. Ukwenza iplate edge V-CUT

Ukuba umda weplate nguMoses V-CUT, amacandelo kufuneka abe kude kumda weplate, kuba ummese we-V-CUT osuka phakathi kweplate uqheleke ngaphezu kwe-0.4mm ukusuka kumda we-V-CUT, ngaphandle koko i-V-CUT i-knife iya kulimaza i-welding plate, okubangela ukuba amacandelo angakwazi ukufakwa.

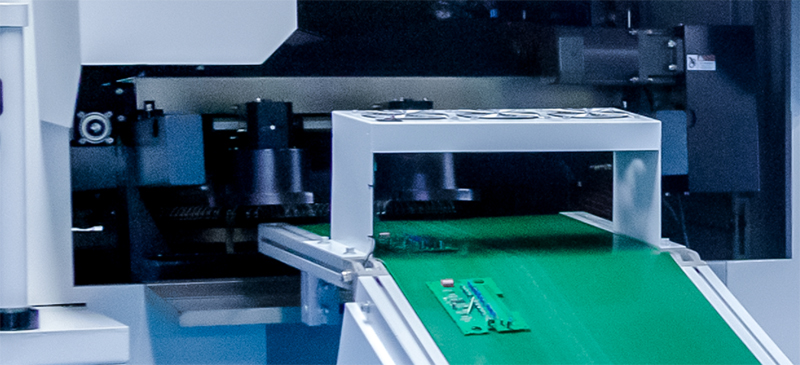

03. Izixhobo zokuphazamiseka kwecandelo

Ukucwangciswa kwamacandelo asondele kakhulu kumda wepleyiti ngexesha loyilo kunokuphazamisa ukusebenza kwezixhobo zokuhlanganisa ngokuzenzekelayo, ezifana ne-wave-soldering okanye i-reflow welding machines, xa kuhlanganiswa amacandelo.

04. Isixhobo siyantlitheka kumalungu

Inxalenye esondeleyo kumda webhodi, inkulu amandla ayo okuphazamisa isixhobo esidibeneyo. Ngokomzekelo, amacandelo afana ne-electrolytic capacitors enkulu, emide kakhulu, kufuneka abekwe kude kumda webhodi kunamanye amacandelo.

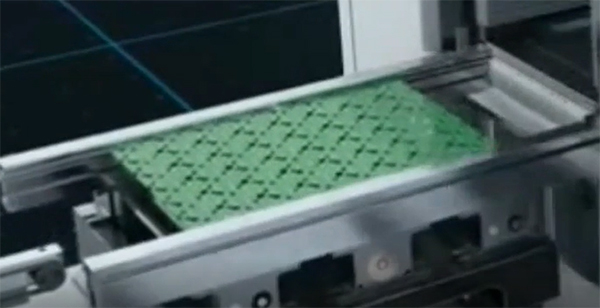

05. Amalungu ebhodi engaphantsi awonakele

Emva kokuba indibano yemveliso igqityiwe, imveliso eqingqiweyo kufuneka ihlulwe kwi-plate. Ngexesha lokwahlula, amacandelo asondele kakhulu kumda angonakaliswa, anokuthi abe phakathi kwaye kube nzima ukuzibona kunye nokucima.

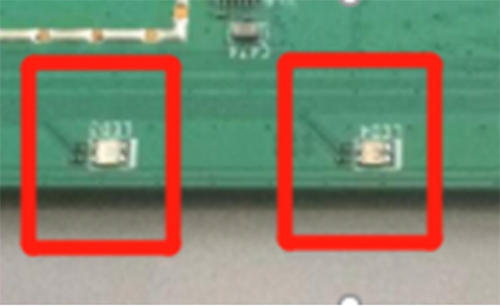

Oku kulandelayo kukwabelana ngemeko yemveliso malunga nomgama wesixhobo somda awonelanga, kukhokelela kumonakalo kuwe ~

Inkcazo yengxaki

Kufunyenwe ukuba isibane se-LED semveliso sisondele kumda webhodi xa i-SMT ibekwe, ekulula ukubethelwa kwimveliso.

Impembelelo yengxaki

Ukuveliswa kunye nokuthutha, kunye nesibane se-LED siya kuphulwa xa inkqubo ye-DIP idlula umzila, oya kuchaphazela umsebenzi wemveliso.

Ukwandiswa kwengxaki

Kuyimfuneko ukutshintsha ibhodi kwaye uhambise i-LED ngaphakathi kwebhodi. Ngexesha elifanayo, kuya kubandakanya utshintsho lwekholamu yesikhokelo sokukhanya kwesakhiwo, okubangela ukulibaziseka okukhulu kumjikelezo wophuhliso lweprojekthi.

Ukufunyanwa komngcipheko wezixhobo ezinqamlekileyo

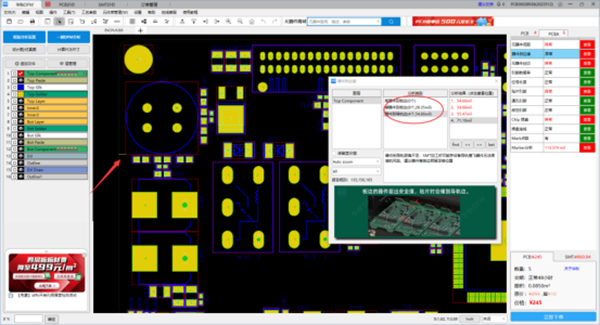

Ukubaluleka koyilo loyilo lwecandelo kuyabonakala, ukukhanya kuya kuchaphazela i-welding, enzima iya kukhokelela ngokuthe ngqo kumonakalo wesixhobo, ngoko ke uqinisekisa njani ukuba iingxaki zoyilo eziyi-0, kwaye emva koko ugqibezele ngempumelelo imveliso?

Ngomsebenzi wokuhlanganisa kunye nokuhlalutya, I-BEST inokuchaza imigaqo yokuhlola ngokweeparamitha zomgama ukusuka kumda wodidi lwecandelo. Ikwanayo nezinto zokuhlola ezikhethekileyo zokubekwa kwamacandelo omda wepleyiti, kubandakanywa izinto ezininzi zokuhlola ezineenkcukacha ezininzi njengesixhobo esiphakamileyo ukuya kumda wepleyiti, isixhobo esisezantsi ukuya kumda weplate, kunye nesixhobo esiya kumda wesikhokelo somatshini, esinokuhlangabezana ngokupheleleyo neemfuno zoyilo lovavanyo lomgama okhuselekileyo wesixhobo ukusuka kumda weplate.

Ixesha lokuposa: Apr-17-2023