Ukuchaneka okuphezulu kwebhodi yesekethe ye-PCBA ye-DIP iplagi-in ekhethiweyo yoyilo lwe-welding welding kufuneka ilandele iimfuno!

Kwinkqubo yendibano ye-elektroniki yemveli, itekhnoloji ye-welding ye-welding isetyenziswa ngokubanzi kwi-welding yamacandelo ebhodi eprintiweyo kunye ne-perforated insert elements (PTH).

I-DIP ye-wave soldering inezinto ezininzi ezingalunganga:

1. Ubuninzi obuphezulu, i-fine-pitch SMD components ayikwazi ukuhanjiswa kwi-welding surface;

2. Zininzi iibhulorho kunye nezinto ezilahlekileyo zokutywina;

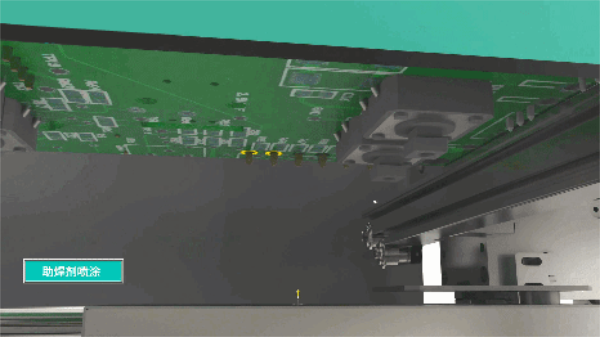

3.I-Flux kufuneka itshizwe; ibhodi eprintiweyo ijijekile kwaye ikhubazeke kukothuka okukhulu kwe-thermal.

Njengoko ingxinano yendibano yesiphaluka yangoku iya inyuka kwaye iphezulu, akunakuphepheka ukuba i-high-density, i-fine-pitch-pitch SMD iza kuhanjiswa kumphezulu we-soldering. Inkqubo yemveli yokuthengisela i-wave soldering ayinamandla okwenza oku. Ngokuqhelekileyo, amacandelo e-SMD kumphezulu we-soldering angaphinda athengiselwe ngokwahlukileyo. , kwaye emva koko ulungise ngesandla i-plug-in eseleyo ye-solder joints, kodwa kukho ingxaki yokungaguquki komgangatho odibeneyo we-solder.

Njengoko i-soldering of through-hole components (ingakumbi umthamo omkhulu okanye i-fine-pitch components) iba nzima ngakumbi nangakumbi, ngakumbi kwiimveliso ezineemfuno ezingenalo ilothe kunye nokuthembeka okuphezulu, umgangatho wokusoda we-soldering manual awusakwazi ukuhlangabezana nezixhobo zombane ezikumgangatho ophezulu. Ngokweemfuno zemveliso, i-wave soldering ayikwazi ukuhlangabezana ngokupheleleyo nemveliso kunye nokusetyenziswa kweebhetshi ezincinci kunye neentlobo ezininzi ekusetyenzisweni okukhethekileyo. Ukusetyenziswa kwe-wave soldering ekhethiweyo kuphuhliswe ngokukhawuleza kwiminyaka yamuva.

Kwiibhodi zesekethe ze-PCBA ezinamacandelo anemingxuma ye-THT kuphela, ngenxa yokuba iteknoloji yokuthengisa i-wave iseyeyona ndlela isebenzayo ngoku, akukho mfuneko yokubuyisela i-soldering yamaza kunye ne-soldering ekhethiweyo, ebaluleke kakhulu. Nangona kunjalo, i-solder ekhethiweyo ibalulekile kwiibhodi zetekhnoloji ezixubeneyo kwaye, kuxhomekeke kuhlobo lombhobho osetyenzisiweyo, iindlela zokuthambisa zamaza zinokuphinda ziphindwe ngendlela entle.

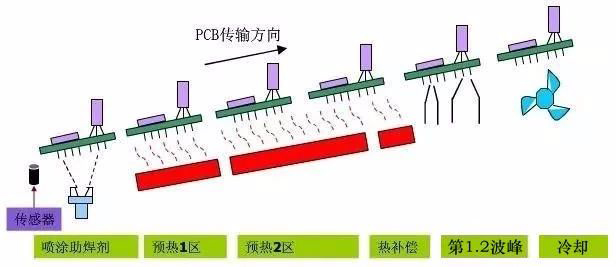

Kukho iinkqubo ezimbini ezahlukeneyo zokukhetha i-soldering: ukutsala i-solder kunye ne-dip soldering.

Inkqubo ekhethiweyo yokutsalwa kwe-solder yenziwa kwinqanaba elincinci elincinci le-solder. Inkqubo yokutsalwa kwe-solder ifanelekile kwi-soldering kwiindawo ezixinene kakhulu kwi-PCB. Umzekelo: i-solder joints okanye izikhonkwane, umqolo omnye wezikhonkwane unokutsalwa kwaye uthengiswe.

Itekhnoloji ekhethiweyo yokuthengisa amaza bubuchwephesha obusanda kuphuhliswa kwitekhnoloji ye-SMT, kwaye inkangeleko yayo ihlangabezana kakhulu neemfuno zendibano zoxinaniso oluphezulu kunye neebhodi zePCB ezixubeneyo ezahlukeneyo. I-solder ekhethiweyo ye-wave soldering inezibonelelo zokusetwa okuzimeleyo kweeparamitha ezidibeneyo ze-solder, ukothuka okuncinci kwe-thermal kwi-PCB, ukutshiza okuncinci, kunye nokuthembeka okuqinileyo kwe-solder. Ngokuthe ngcembe iba bubuchwephesha obuyimfuneko bokuthengisa kwiiPCB ezintsonkothileyo.

Njengoko sisazi sonke, inqanaba loyilo lwebhodi yesekethe yePCBA limisela i-80% yeendleko zokwenziwa kwemveliso. Ngokufanayo, iimpawu ezininzi zomgangatho zilungiswa ngexesha loyilo. Ke ngoko, kubaluleke kakhulu ukuqwalasela ngokupheleleyo imiba yokuvelisa kwinkqubo yoyilo lwebhodi yesekethe yePCB.

I-DFM efanelekileyo yindlela ebalulekileyo ye-PCBA yokunyuka kwecandelo abavelisi ukunciphisa iziphene zokuvelisa, ukwenza lula inkqubo yokuvelisa, ukunciphisa umjikelo wokuvelisa, ukunciphisa iindleko zokuvelisa, ukwandisa ulawulo lomgangatho, ukwandisa ukhuphiswano lwemarike yemveliso, kunye nokuphucula ukuthembeka kwemveliso kunye nokuqina. Inokwenza ukuba amashishini afumane ezona nzuzo zingcono notyalo-mali oluncinci kwaye aphumelele kabini isiphumo ngesiqingatha somzamo.

Uphuhliso lwamacandelo okunyuka komphezulu ukuza kuthi ga namhlanje kufuna ukuba iinjineli ze-SMT zinganeli nje ukuba nobuchule kubuchwephesha boyilo lwebhodi yesekethe, kodwa nokuba zibe nokuqonda okunzulu kunye namava atyebileyo asebenzayo kwitekhnoloji ye-SMT. Ngenxa yokuba umyili ongaziqondi iimpawu zokuhamba kwe-solder paste kunye ne-solder ngokuqhelekileyo kunzima ukuqonda izizathu kunye nemigaqo ye-bridging, i-tipping, i-tombstone, i-wicking, njl., kwaye kunzima ukusebenza nzima ukuyila iphethini ye-pad ngokufanelekileyo. Kunzima ukujongana nemiba yoyilo eyahluka-hlukeneyo ngokweembono zokwenziwa koyilo, ukuvavanywa, kunye nokunciphisa iindleko kunye neendleko. Isisombululo esiyilwe ngokugqibeleleyo siya kubiza iindleko ezininzi zokuvelisa kunye nokuvavanya ukuba i-DFM kunye ne-DFT (uyilo lokubonwa) ihluphekile.